Electric vacuum servo brake control system of pure electric automobile

A pure electric vehicle, vacuum boost technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of poor braking effect, hidden dangers, vehicle performance and driving safety restrictions, etc., to ensure sensitivity and reliability, The effect of ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

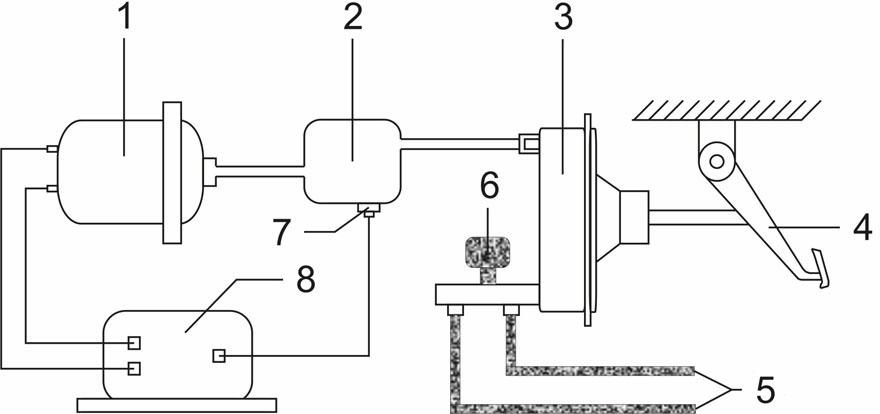

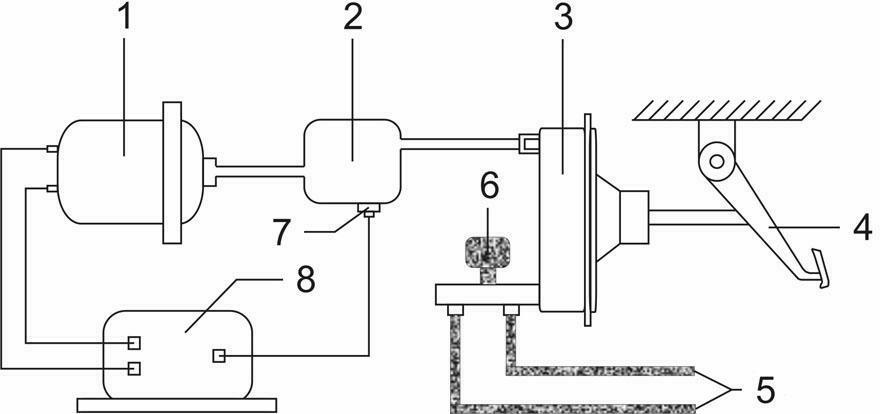

[0050] Such as figure 1 The pure electric vehicle brake booster control system includes: 1 vacuum pump, 2 vacuum air storage tank, 3 booster master cylinder assembly, 4 brake pedal, 5 brake oil circuit, 6 oil storage tank, 7 pressure sensor, 8 vacuum booster Brake controls. The booster master cylinder assembly 3 and the brake pedal 4 form a link mechanism, which is used to provide boost for the brake pedal 5. The booster master cylinder assembly 3 is connected to the vacuum air storage tank 2 by a vacuum pipeline, and the vacuum air storage tank 2 and then connected to the vacuum pump 1 via the vacuum pipeline, the vacuum air storage tank 2 is provided with a pressure sensor 7, the brake vacuum booster controller 8 is electrically connected with the pressure sensor 7 and the vacuum pump 1, and is used to detect the vacuum air storage tank 2 through the pressure sensor 7 The size of the vacuum pressure value, and then through the brake vacuum booster controller 8 to control th...

Embodiment 2

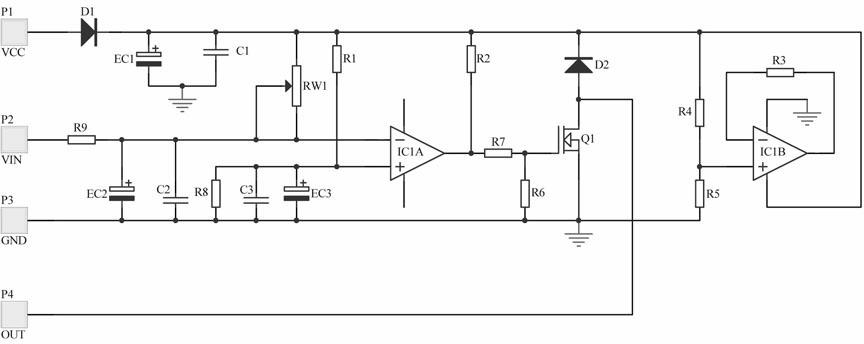

[0053] Such as figure 2 It is a schematic diagram of the principle of the vacuum booster brake control device provided by the present invention.

[0054] figure 2 R1, R2, R3, R3, R4, R5, R6, R7, R8, R9 represent resistors, C1, C2, C3 represent capacitors, EC1, EC2, EC3 represent electrolytic capacitors, RW1 represent adjustable resistors, D1, D2 Represents a diode, Q1 represents a MOS transistor, IC1A and IC1B represent a comparator, VCC represents a power input terminal, VIN represents a signal input terminal, GND represents a ground terminal, and OUT represents an output terminal.

[0055] As shown in the figure, the hardware control circuit includes, D1, EC1, C1 composed of power supply reverse connection protection and power filtering, R1, R8, EC3, C3 provide the comparison voltage threshold of comparator IC1A, the voltage threshold range can be It is set according to the specific situation. Preferably, the voltage threshold is half of the power supply voltage, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com