Small-sized five-axis machining center

A five-axis machining center, small technology, used in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low degree of freedom of tool operation, insufficient equipment processing flexibility and mobility, etc., to reduce the difficulty of cleaning , Improve processing flexibility and mobility, the effect of compact machine tool structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

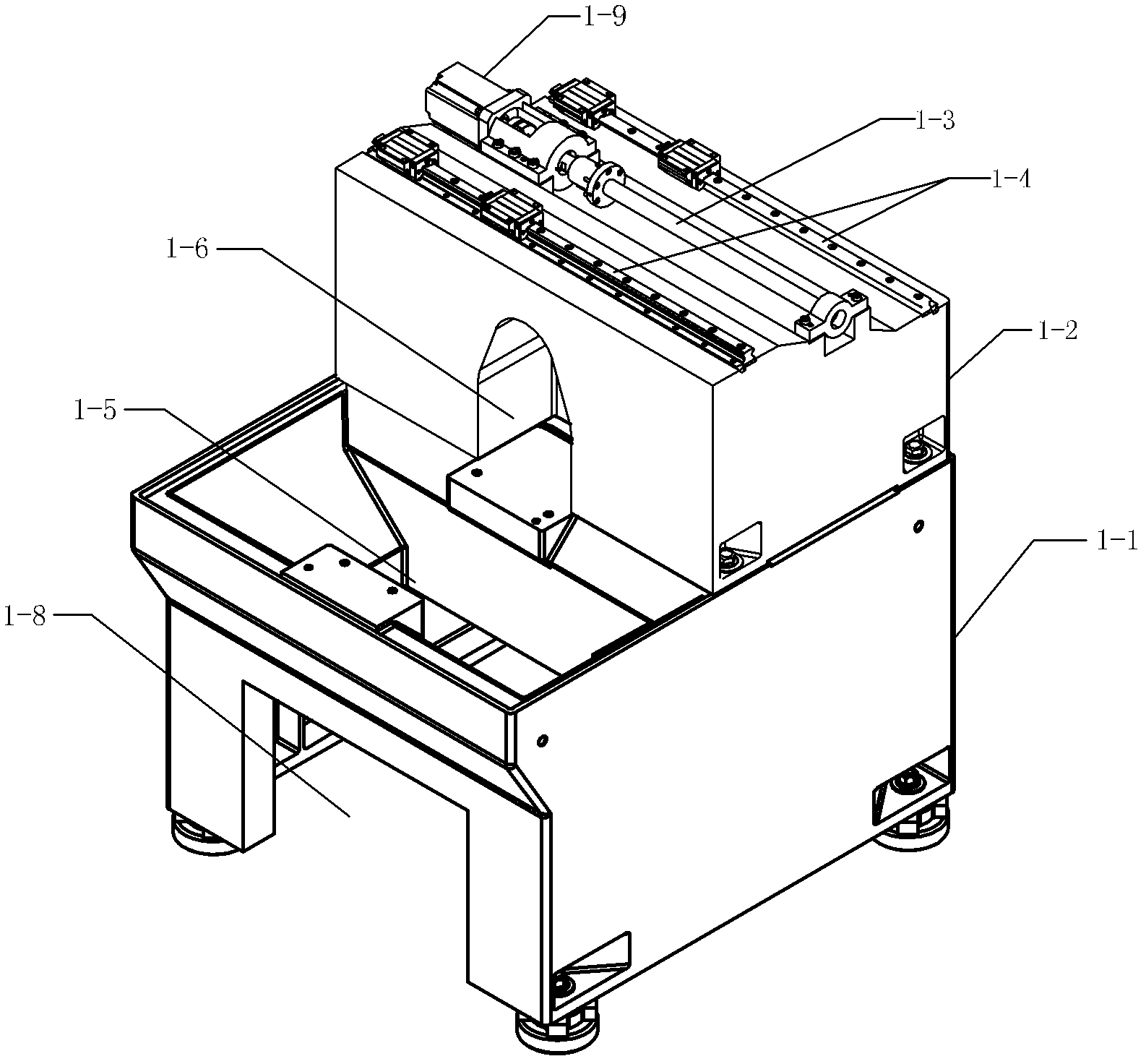

[0037] Figure 1-Figure 10 Constitute the specific embodiment 1 of the present invention.

[0038] refer to Figure 1-Figure 10 , this embodiment includes a base structure 1, an XYZ vertical axis structure 2 and a BC turntable structure 3,

[0039] 1) The base structure 1 is L-shaped, including an X-axis base 1-2 and a hollow machine tool base 1-1. The X-axis base 1-2 is set on the machine tool base 1-1, and the two are integrally formed Structure or fixed connection forming structure, X-axis ball screw 1-3, Y-axis ball screw 2-6, Z-axis ball screw 2-4 and two X-axis guide rails 1 are arranged on the X-axis base 1-2 -4, two Y-axis guide rails 2-7, two Z-axis guide rails 2-5; the BC turntable structure 3 is set on the table top of the machine tool base 1-1 and is located next to the front of the X-axis base 1-2; on the machine tool base 1 -1 is equipped with a funnel-shaped chip removal port 1-5, and a BC turntable structure 3 connection hole 1-6 is provided on the front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com