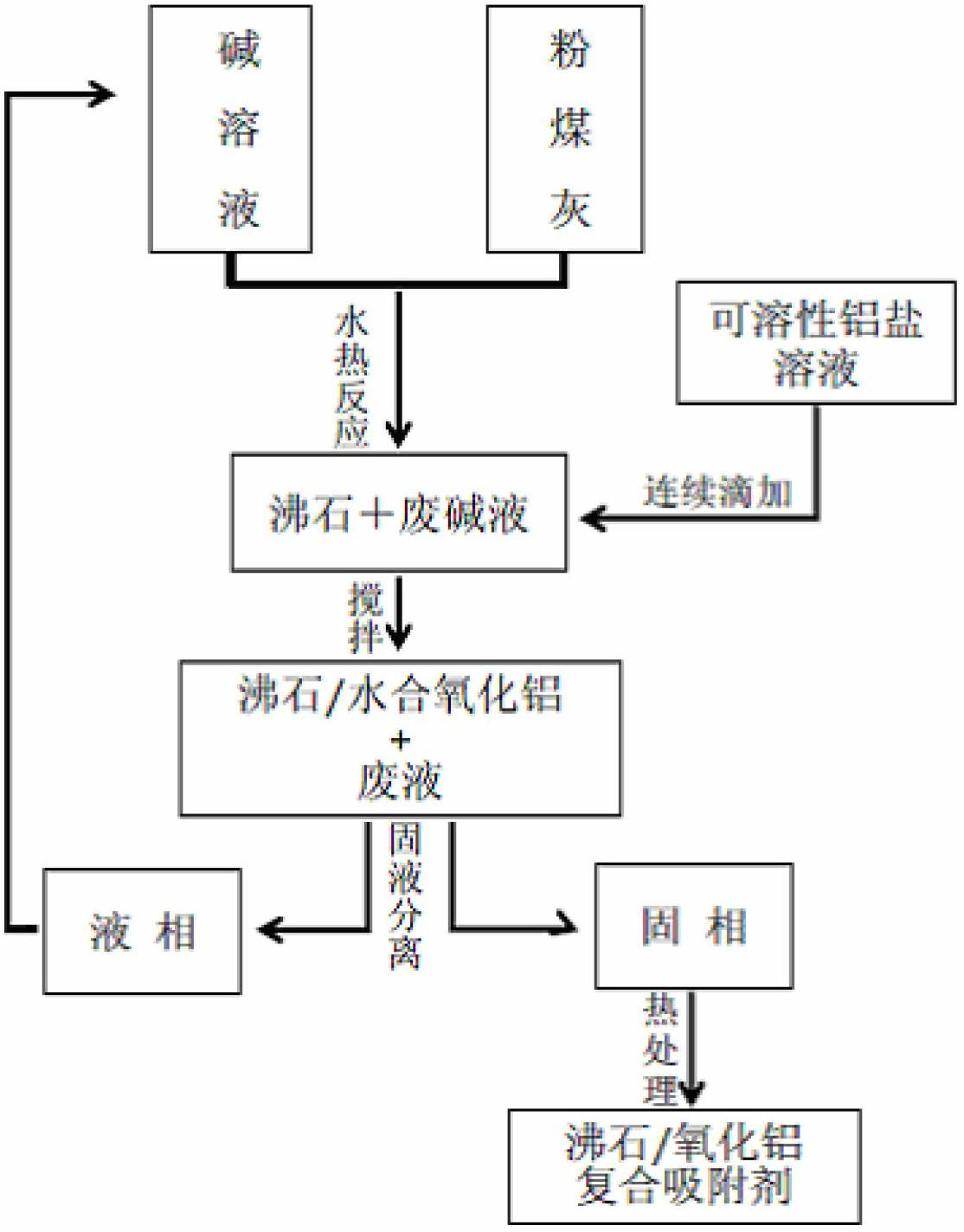

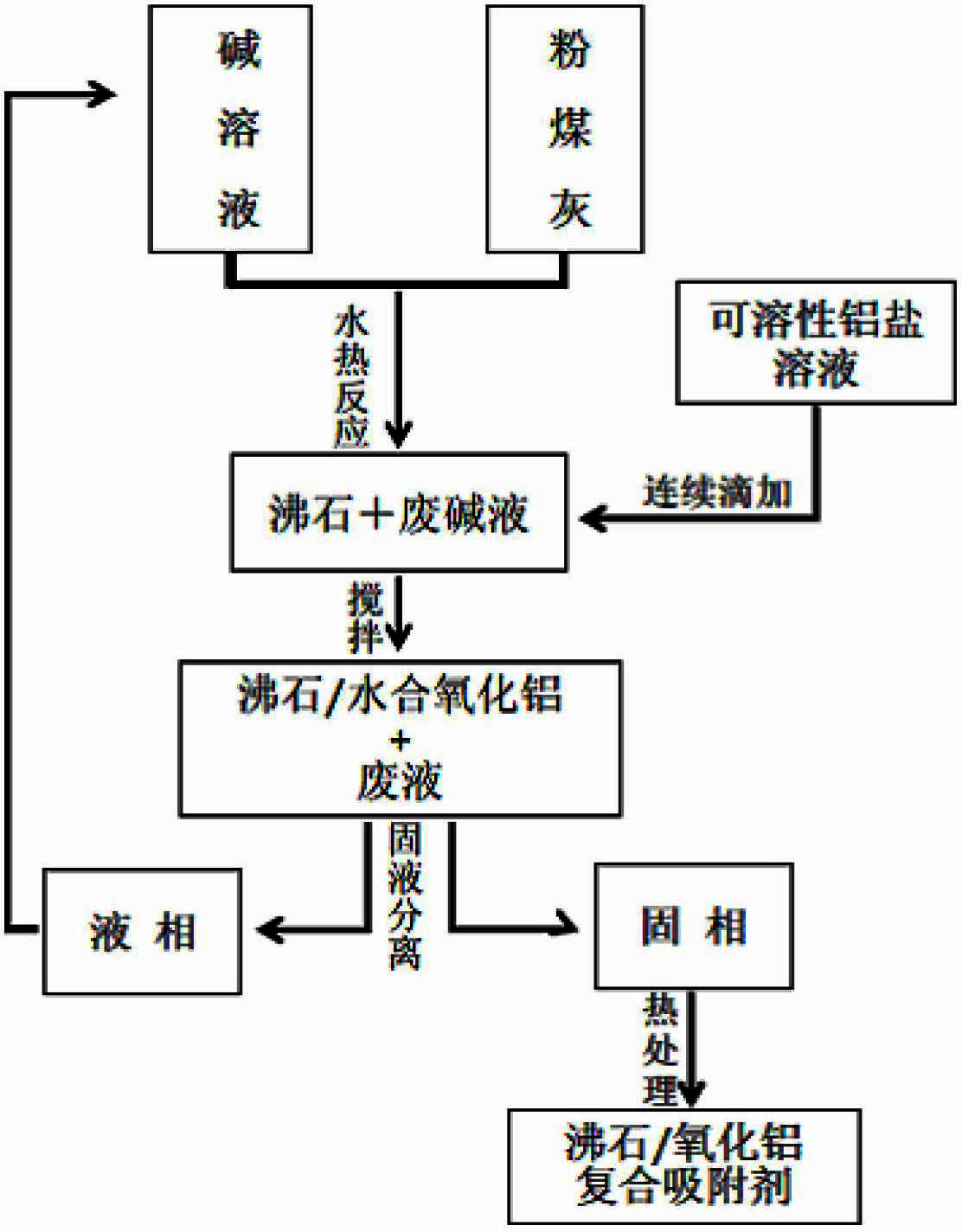

Preparation method of fly ash based zeolite / alumina composite adsorbing material

A composite adsorption material and fly ash technology, applied in the environmental field, can solve the environmental hazards of waste lye and other problems, achieve high effects of ammonia and phosphorus removal, realize the resource utilization of nitrogen and phosphorus in sewage, and solve environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1, add 2M (molar concentration) sodium hydroxide solution and fly ash into the double-layer glass reactor (open system) according to the liquid-solid ratio of 10:1 (L / kg), control the temperature of the reactor at 80°C, and the stirring speed 120 rpm, after hydrothermal reaction for 24 hours, cool the suspension to room temperature.

[0032] Step 2, dissolving aluminum chloride hexahydrate in water to prepare an aqueous aluminum chloride solution with a concentration of 0.5M (molar concentration). The aluminum chloride solution was added into the glass reactor by continuous titration, the titration rate was 10ml / min, the stirring rate was 60rpm, the reaction temperature was 20°C, and the end point pH was 6.0. After the reaction is completed, it is centrifuged and the obtained liquid is collected and used for the subsequent preparation of sodium hydroxide solution; the obtained solid is calcined in a muffle furnace for 2 hours at a calcining temperature of 250°C to ...

Embodiment 2

[0035] Step 1, add 5M (molar concentration) potassium hydroxide solution and fly ash into the double-layer glass reactor (open system) according to the liquid-solid ratio of 1.5:1 (L / kg), control the temperature of the reactor at 100°C, and the stirring speed 120 rpm, after hydrothermal reaction for 12 hours, cool the suspension to room temperature.

[0036] Step 2, dissolving aluminum chloride hexahydrate in water to prepare an aqueous aluminum chloride solution with a concentration of 2.5M (molar concentration). The aluminum chloride solution was added into the glass reactor by continuous titration, the titration speed was 50ml / min, the stirring speed was 60rpm, the reaction temperature was 20°C, and the end point pH was 7.0. After the reaction is completed, it is centrifuged, and the obtained liquid is collected and used for the subsequent preparation of potassium hydroxide solution; the obtained solid is dried at 105° C. for 4 hours, and the zeolite / alumina composite adsor...

Embodiment 3

[0039] Step 1: Add 1M (molar concentration) sodium hydroxide solution and fly ash to the stainless steel reaction kettle (closed system) according to the liquid-solid ratio of 6:1 (L / kg), control the temperature of the reaction kettle to 200°C, and the stirring speed to 80rpm , after hydrothermal reaction for 3 hours, the suspension was cooled to room temperature.

[0040] Step 2, dissolving aluminum chloride hexahydrate in water to prepare an aqueous aluminum chloride solution with a concentration of 5M (molar concentration). The aluminum chloride solution was added into the stainless steel reaction kettle by continuous titration, the titration speed was 100ml / min, the stirring speed was 60rpm, the reaction temperature was 25°C, and the terminal pH was 5.5. After the reaction is completed, filter and separate, the obtained liquid is collected and continued to be used for the subsequent preparation of sodium hydroxide solution; the obtained solid is calcined in a muffle furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com