Reactor and method for producing particle materials

A particle material and reactor technology, applied in chemical instruments and methods, carbon preparation/purification, chemical/physical processes, etc., can solve problems such as affecting product collection, reducing product yield, reducing product yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

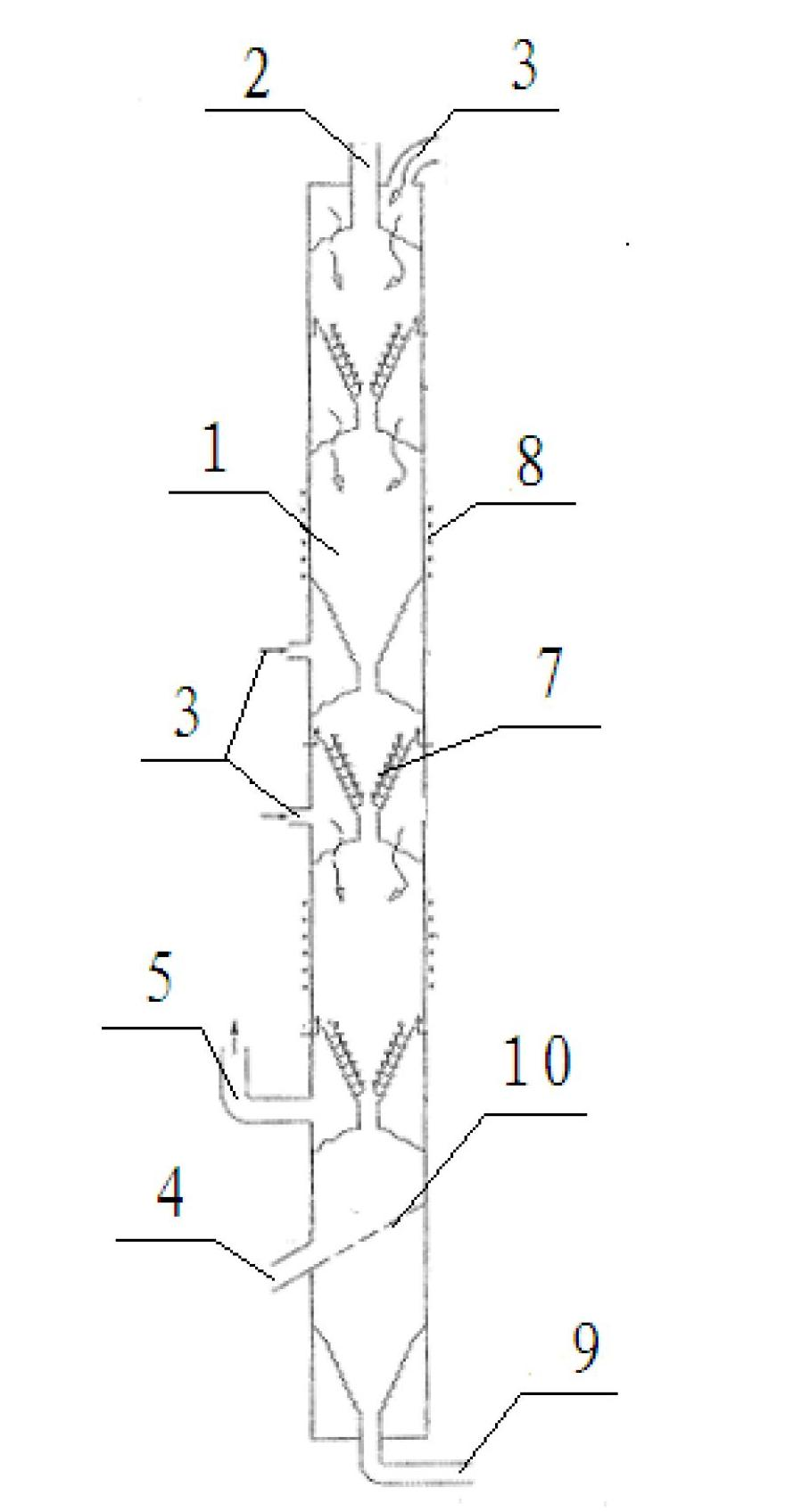

[0092] Figure 1a The schematic diagram of the reactor for producing granular materials provided in the first embodiment; Figure 1b for Figure 1a Schematic diagram of the structure of the mid-cone distributor; figure 2 Schematic diagram of the structure of the particle transport mechanism; Figure 3a , Figure 3b Is a schematic diagram of the structure of the reactor cavity gas curtain; Figure 3c , Figure 3d It is a schematic diagram of the structure of the gas curtain of the raw gas inlet pipe.

[0093] The reactor for producing particulate material provided in this implementation is used to generate particulate material (silicon) from the pyrolysis of raw material gas (silane).

[0094] Such as Figure 1a The reactor shown for producing granular materials includes: a reactor cavity 1;

[0095] The reactor cavity 1 is provided with at least a particle feeding hopper 2, a raw material gas inlet 3, a particle product discharge port 4, and a tail gas outlet 5. Among them, the reactor ...

Embodiment 2

[0129] This embodiment discloses a method for producing granular materials by using a reactor for producing granular materials to thermally decompose nickel carbonyl to prepare nickel granular materials, including the following steps:

[0130] a. Add the nickel granular material seeds into the reactor cavity through the particle feeding hopper, so that the nickel granular material seeds form a stacked particle bed in the reaction zone, and the filling rate of the nickel granular material seeds in the stacked particle bed is above 60%; The filling rate is the volume of the nickel granular material seeds occupying the reaction zone.

[0131] b. Use the variable diameter reactor cavity and change the speed of replenishing the nickel granular material seeds to control the residence time of the nickel granular material seeds in the reactor cavity, and make the nickel granular material seeds in the stacked granular bed in a relative motion state ;

[0132] Heating the stacked particle bed...

Embodiment 3

[0137] Figure 4 The schematic diagram of the reactor for producing high-purity silicon granular material provided in Example 3.

[0138] by Figure 4 It can be seen that the reactor for producing high-purity silicon granular materials provided in this embodiment is an internally-moving close-packed bed reactor, which can be used for other related reactions such as pyrolysis of silane to generate granular high-purity silicon.

[0139] As shown in the figure, the reactor includes a reactor cavity. The bottom of the reactor cavity is an inverted cone. An auxiliary gas inlet 414 is provided at the lower end of the inverted cone. The auxiliary gas inlet 414 can be used to transport auxiliary gas (hydrogen); The side wall in the middle of the cavity is provided with a shutter distributor and a tail gas outlet 416; the top of the reactor cavity is provided with a seed feeding port 401 and a raw material gas inlet 415; the upper end of the reactor cavity side wall distributor is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com