Filter element with at least one opening

A filter and element technology, which is used in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of filter element contamination and envelope damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

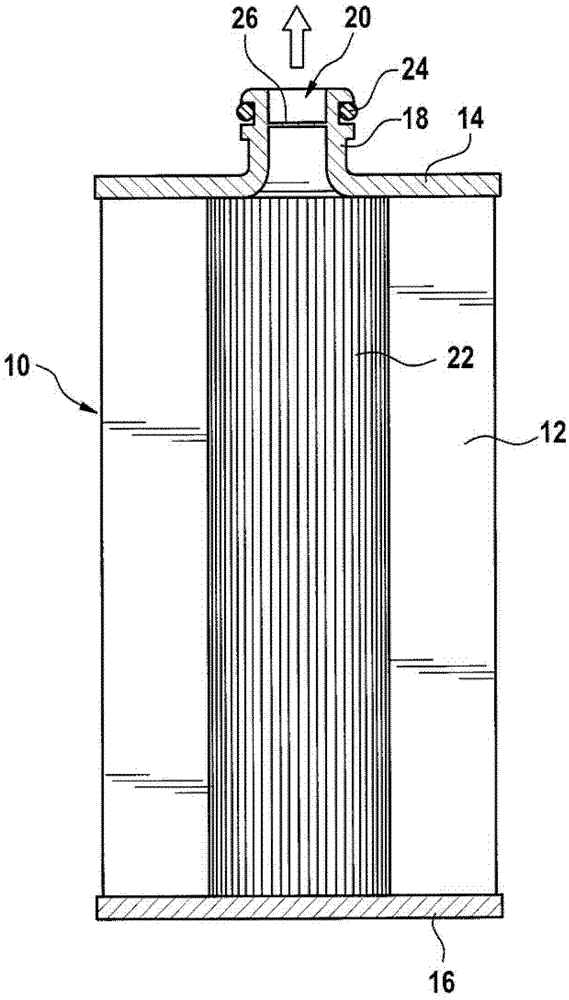

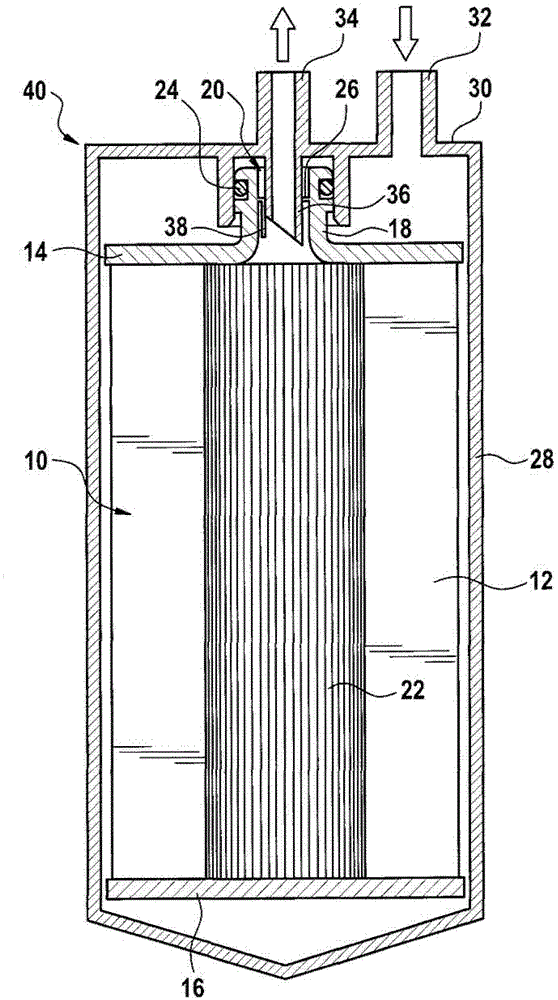

[0020] exist figure 1 shows a filter element 10 which is constructed in the form of a filter insert and here comprises a cylindrical filter body 12 made of felt or cardboard and two filter bodies arranged on the end faces of the filter body Connect pads 14 and 16. These connection pads 14 and 16 are about figure 1 The lower connection plate 16 is closed over its entire surface, while the upper connection plate 14 has a centrally arranged pipe connection 18 . This pipe connection 18 protrudes perpendicularly from the upper connection plate 14 on the side facing away from the filter body 12 and has an opening 20 in itself, which is used to discharge fluid in the form of fuel from the interior of the filter body 12 The space 22 is led out to protrude outward. The pipe connection 18 here has a sealing element 24 in the form of a sealing ring on its outer circumference and a closure device 26 inside it, figure 1 In the delivery state of the filter element 10 shown in , the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com