Sonodynamic liposomal material, preparation method and application thereof in preparing pharmorubicin composite liposomal

A technology of epirubicin and compound lipids, applied in the field of medicine, can solve the problems of low tumor cell selectivity, increased drug efficacy, and increased toxicity, and achieve the effects of simple operation methods, reduced toxic and side effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

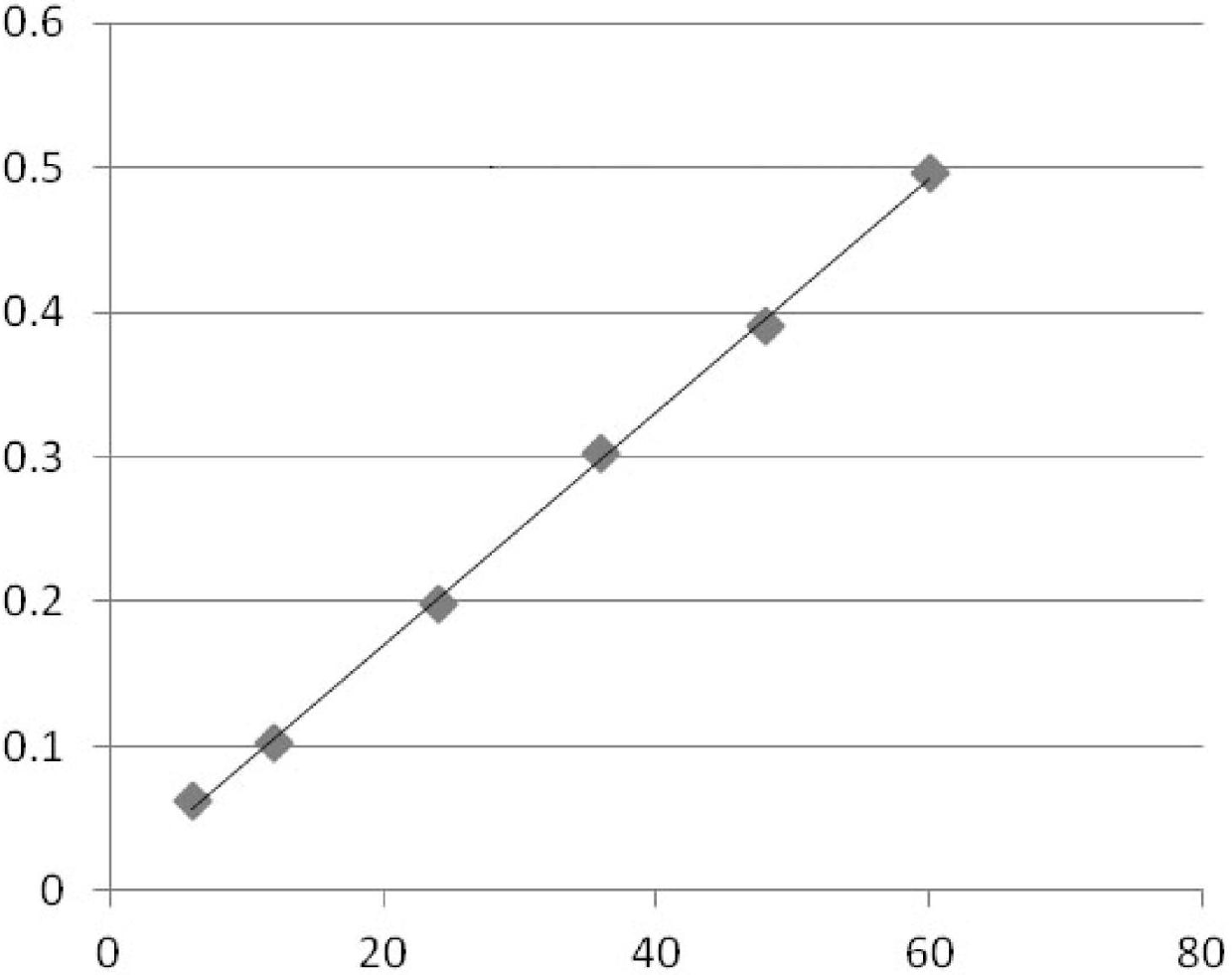

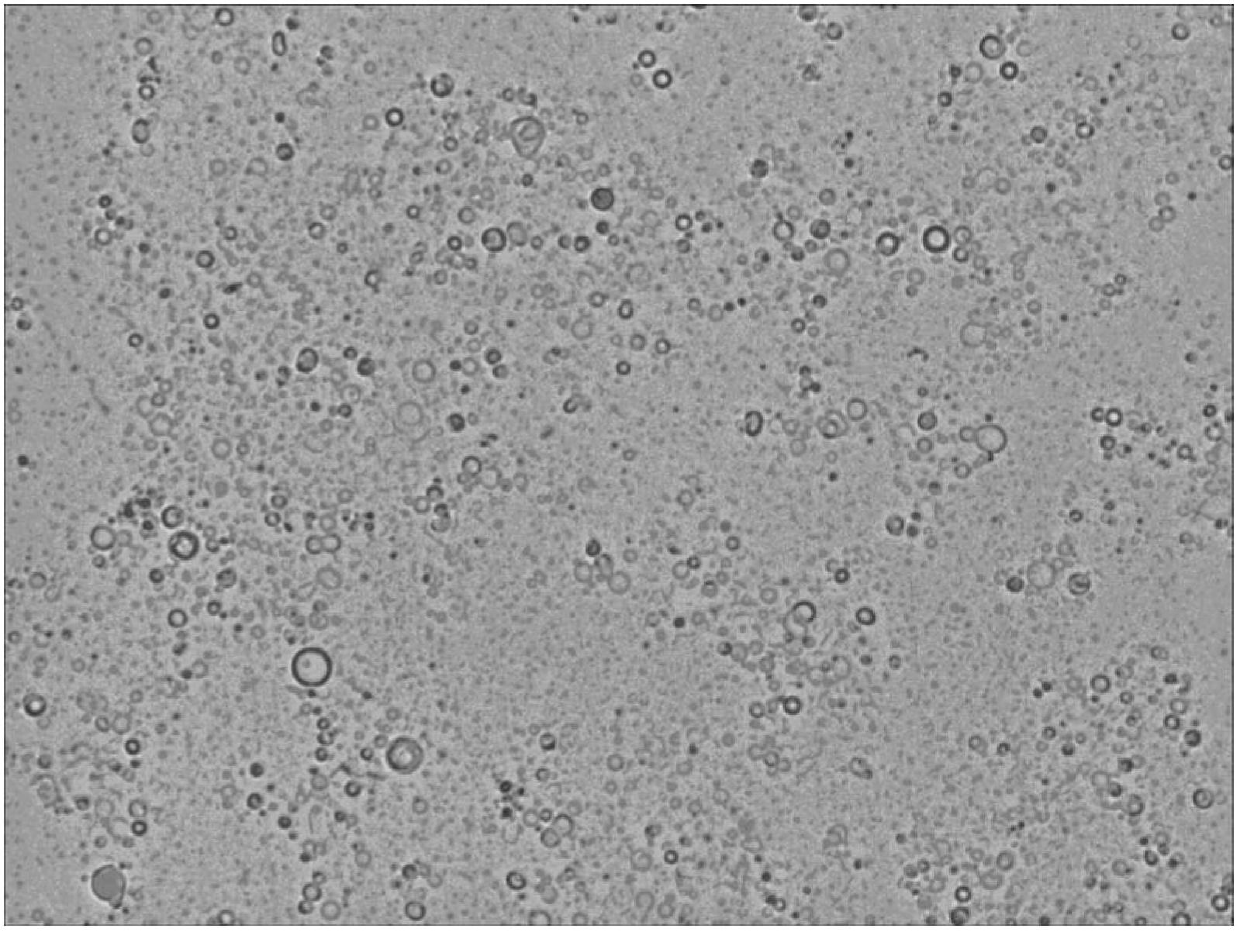

[0035] (1) Prepare complex liposomes by combining film dispersion-pH gradient method, dissolve 30mg lecithin, 10mg cholesterol and 5mg chlorin e4 in chloroform to obtain a mixture, and place the mixture in a rotary evaporator under normal pressure Rotate and mix for 5 minutes to fully mix chlorin e4 and lecithin evenly, then vacuumize the rotary evaporator to 0.09Mpa and perform rotary evaporation to evaporate the chloroform to dry up a white translucent film. The rotary evaporation temperature is 35 ℃, add 3ml of citrate buffer solution with a temperature of 35℃ and a pH of 4 to the white translucent film, then add 0.5ml of surfactant Tween 20, then rotate and mix at 40℃ for 2 hours Hydrate the white translucent film, then turn it into a constant temperature magnetic stirrer and stir at 1500 rpm for 30 minutes. After stirring, use a probe ultrasonic machine for ultrasonic treatment for 10 minutes with an ultrasonic power of 450 watts to obtain liposome materials. See figure ...

Embodiment 2

[0038] (1) The complex liposomes were prepared by combining thin film dispersion-pH gradient method, 40mg lecithin, 10mg cholesterol and 5mg chlorin e4 were dissolved in chloroform to obtain a mixture, and the mixture was placed in a rotary evaporator for normal Press and rotate and mix for 10 minutes to fully mix chlorin e4 and lecithin evenly, then vacuumize the rotary evaporator to 0.09Mpa and then carry out rotary evaporation to evaporate the chloroform to dry up a white translucent film. The rotary evaporation temperature is 37°C, add 3.5ml of citrate buffer solution with a temperature of 38°C and a pH of 4 to the white translucent film, then add 0.7ml of surfactant Tween 40, then rotate and mix at 50°C under normal pressure Hydrate the white translucent film in 1 hour, then transfer to a constant temperature magnetic stirrer and stir at 1500 rpm for 30 minutes, after stirring, use a probe ultrasonic machine for ultrasonic treatment for 5 minutes, with an ultrasonic power ...

Embodiment 3

[0041] (1) Prepare complex liposomes by combining thin film dispersion-pH gradient method, dissolve 20mg lecithin, 10mg cholesterol and 5mg chlorin e6 in chloroform to obtain a mixture, and place the mixture in a rotary evaporator under normal pressure Rotate and mix for 15 minutes to fully mix chlorin e6 and lecithin evenly, then vacuumize the rotary evaporator to 0.09Mpa and perform rotary evaporation to evaporate chloroform to obtain a white translucent film. The rotary evaporation temperature is 40 ℃, add 4mL of citrate buffer solution with a temperature of 40℃ and a pH of 5 to the white translucent film, then add 1mL of surfactant Tween 60, and then rotate and mix at 60℃ for 1.5 hours under normal pressure to make the white The translucent membrane was hydrated, then transferred to a constant temperature magnetic stirrer and stirred at 1500 rpm for 30 minutes, after stirring, it was ultrasonically treated with a probe ultrasonic machine for 15 minutes, with an ultrasonic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com