Preparation method for recombined coarse cereal food

A technology for miscellaneous grains and food, applied in the field of food processing, can solve the problems of rough taste of miscellaneous grain products, failure to be used as main food, low-value utilization, etc., and achieve the effects of saving preparation cost, improving value and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 cereals recombined rice

[0022] (1) Wash corn, buckwheat, black rice, black beans, bran, barley, mung beans and yam respectively, dry, crush, and pass through an 80-mesh sieve;

[0023] (2) According to 41% corn flour, 22% buckwheat flour, 14% black rice flour, 12% black bean flour, 4% bran flour, 3.4% barley flour, 2.2% mung bean flour and 1.4% yam flour, weigh various raw materials ,well mixed;

[0024] (3) Put the evenly mixed formula powder into the conditioner, and add water with a mass percentage of 20% at the same time for conditioning;

[0025] (4) Put the quenched and tempered material into the single-screw extruder, set the extrusion screw speed of the single-screw extruder to 45rpm, control the temperature of the three-stage barrel at 108°C~115°C~125°C, and the discharge end machine The barrel temperature is 95°C, the cutting machine speed is 1000rpm, and the template is a 32-hole oval-hole template for extrusion and cuttin...

Embodiment 2

[0028] Example 2 Sensory Evaluation Research of Cereals Reconstituted Rice

[0029] Select 10 reviewers to form a review team, and arrange them in a spacious, bright, and quiet room, one for each person, without interfering with each other. The evaluation time is set at 2 hours before the meal. Before the tasting, the reviewers are not allowed to smoke or eat sugar, and rinse their mouths with warm water to remove the residues in the mouth. Divide the prepared mixed-grain rice-type nutritional fortifier rice samples evenly on each white porcelain plate, and evaluate one plate per person, and do not explain the situation of the samples to the evaluation personnel. The results of the judging are recorded on the scoring sheet.

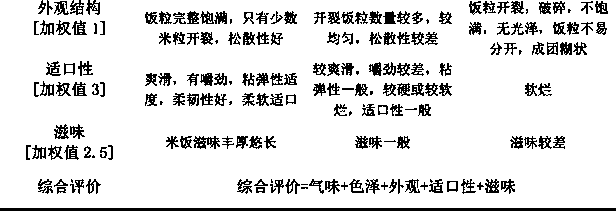

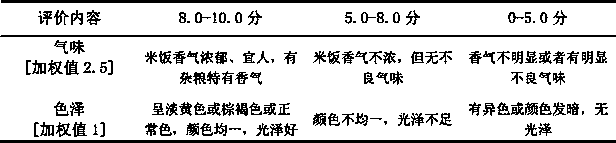

[0030] The content of the evaluation is: the color, aroma, taste, appearance, palatability (including viscosity, elasticity, hardness) and taste of the rice. When tasting, first identify the smell of the rice while it is hot, then observe the color, app...

Embodiment 3

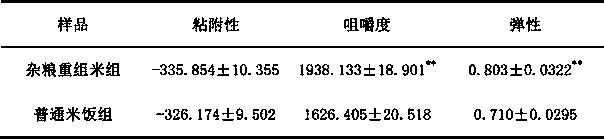

[0040] Example 3 Research on Texture Properties of Cereals Reconstituted Rice of the Present Invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com