Process for extracting rice slag protein by organic solvent washing method

A rice dregs and protein technology, which is applied in the field of food research and development, can solve the problems of high enzyme activity requirements, low product protein purity, and low rice protein efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

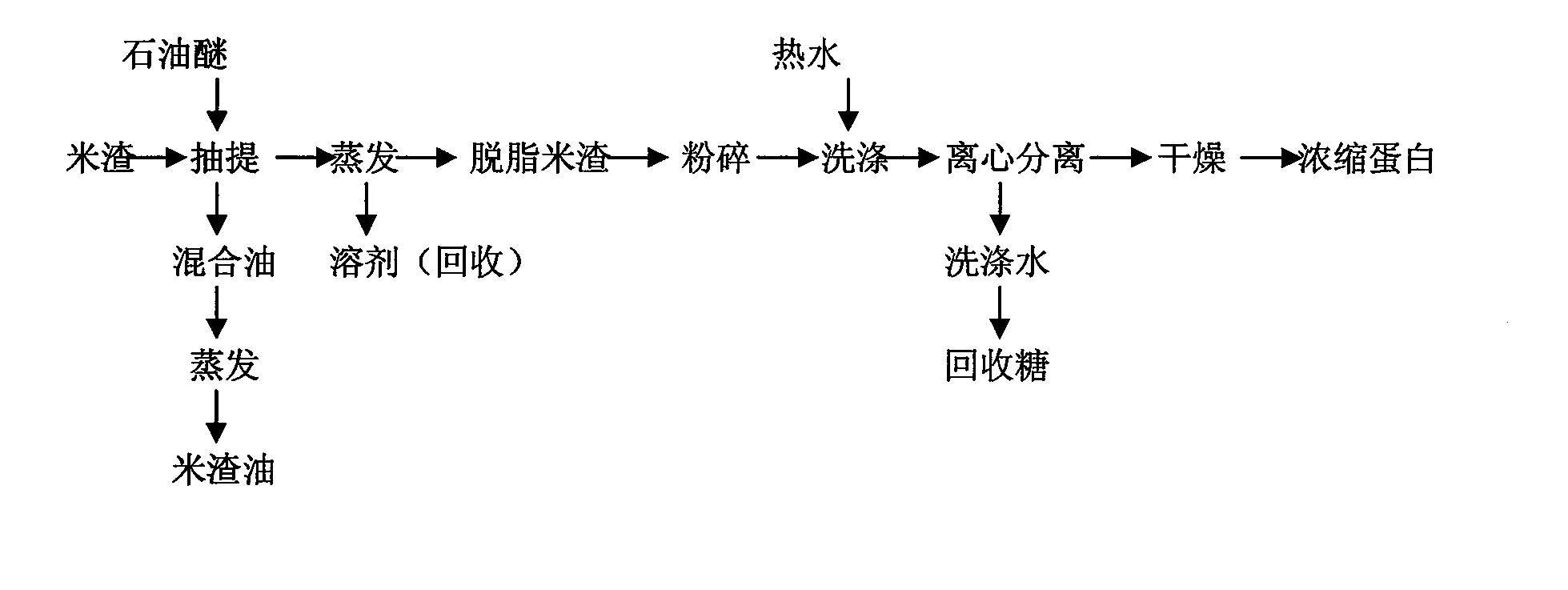

Method used

Image

Examples

Embodiment 1

[0023] Step (2): Evaporate the rice dregs solution from which the mixed oil has been removed (recover the solvent) to obtain defatted rice dregs, crush and sieve;

[0024] Step (3): Add the above defatted rice dregs into hot water at 75°C according to the material-to-liquid ratio of 1:8, soak for 0.5 hours, stir, and centrifuge at 4000r / min to remove free sugar and leave the precipitate;

[0025] Step (4): Repeat the above step (3) once;

[0026] Step (5): spray drying the precipitate in step (4);

[0027] Step (6): packing the product in the step (5).

[0028] Example 2:

Embodiment 2

[0030] Step (2): Evaporate the rice dregs solution from which the mixed oil has been removed (recover the solvent) to obtain defatted rice dregs, crush and sieve;

[0031] Step (3): add the above defatted rice dregs to 85°C hot water according to the material-to-liquid ratio of 1:9, soak for 1 hour, stir, and centrifuge at 4000r / min to remove free sugar and keep the precipitate;

[0032] Step (4): Repeat the above step (3) once;

[0033] Step (5): spray drying the precipitate in step (4);

[0034] Step (6): packing the product in the step (5).

[0035] Attached experimental example:

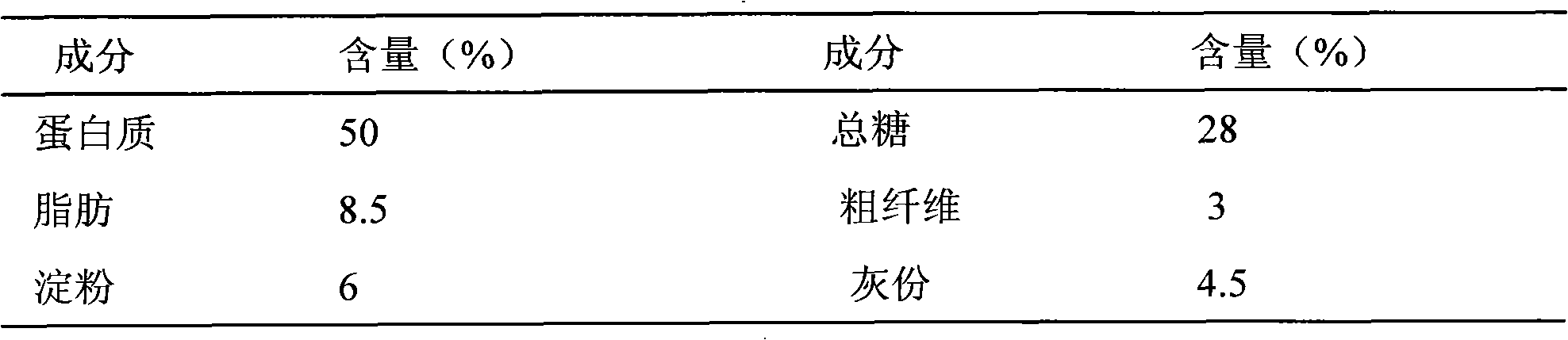

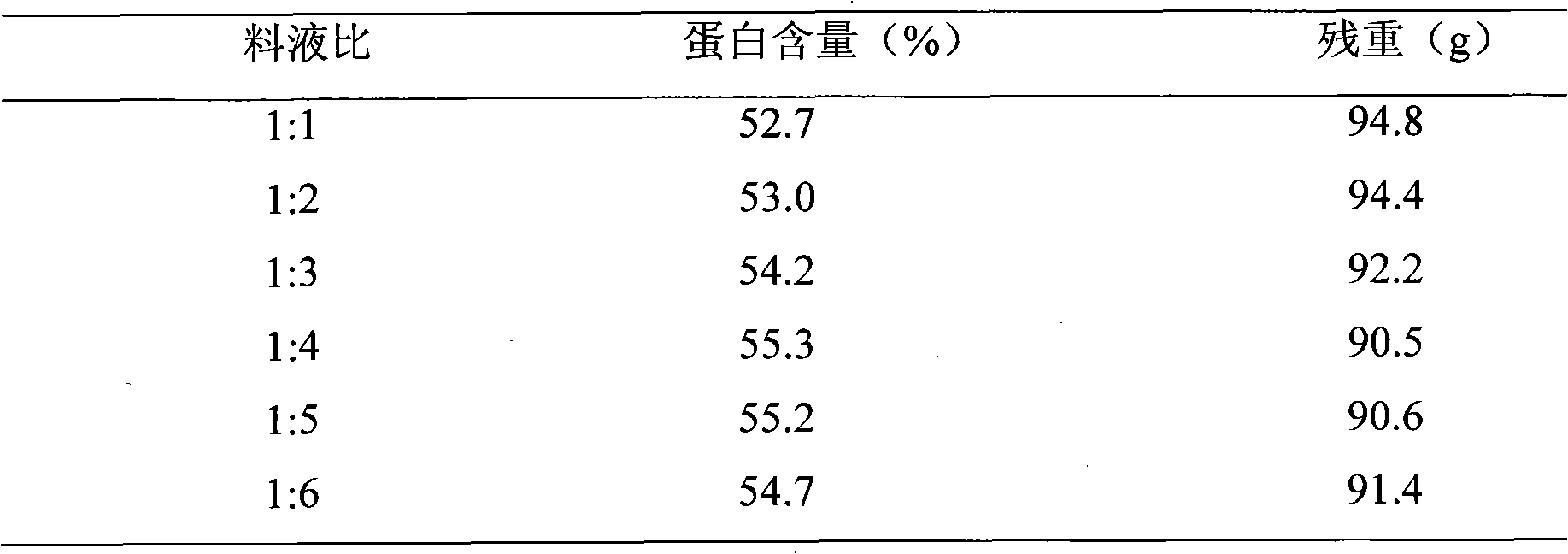

[0036] Study on Extraction of Rice Dregs Protein by Organic Solvent Washing

[0037] 1 Materials and methods

[0038] 1.1 Materials

[0039] Rice dregs: (Shandong Zhengde Food Co., Ltd.), made by drying the solid dregs obtained from rice saccharification and filtration

[0040] Petroleum ether (30-60°C boiling range) (Tianjin Standard Technology Co., Ltd., crystalline bovine serum albumin (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com