Method for making phaseolus coccineus and green tea biscuit

A production method and green tea technology, applied in the field of biscuits, can solve the problems of high price and failure to become popular, and achieve the effects of low cost, prolonged food shelf life, and strong market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

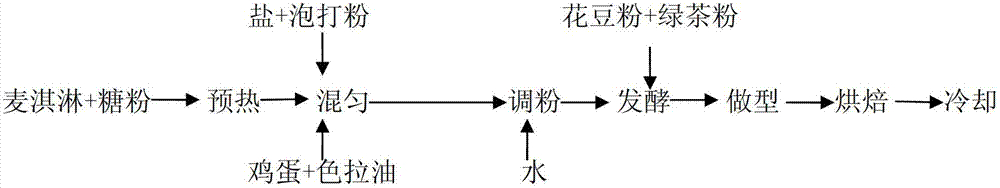

Method used

Image

Examples

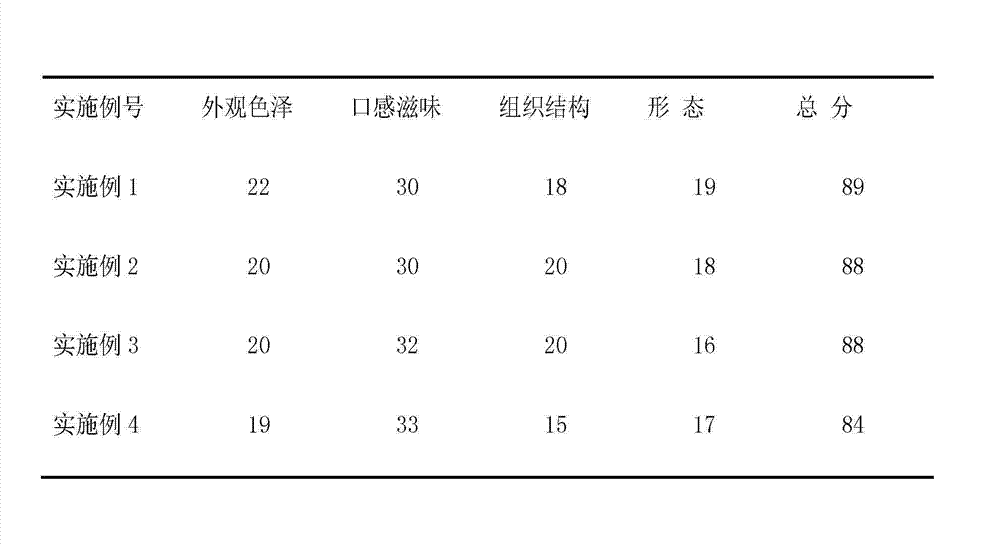

Embodiment 1

[0028] A. Raw material crushing: crush green tea and pinto bean respectively to make green tea powder and pinto bean powder, so that the particle size of both can reach more than 800 mesh;

[0029] B. Weighing: Weigh 100 parts of flour, 3 parts of green tea powder, 7 parts of flower bean powder, 50 parts of Maggie powder, 35 parts of powdered sugar, 6 parts of salad oil, 50 parts of eggs, and 0.7 parts of table salt in parts by weight. , 1.4 parts of baking powder, 18 parts of water;

[0030] C. Preheating: put the weighed margarine and powdered sugar in a container, and put it in an oven to preheat for 15 minutes, and the oven temperature is set at 40°C;

[0031] D. Mixing: Beat the preheated margarine and powdered sugar until there are no obvious white powdered sugar particles, then add eggs and continue to beat until the surface starts to foam, then add salad oil, salt, foam Beat the powder and continue to beat until the surface foams and turns white to form the initial ma...

Embodiment 2

[0036] A. Raw material crushing: crush green tea and pinto bean respectively to make green tea powder and pinto bean powder, so that the particle size of both can reach more than 800 mesh;

[0037] B. Weighing: Weigh 100 parts of flour, 4.5 parts of green tea powder, 7 parts of flower bean powder, 50 parts of Maggie powder, 40 parts of powdered sugar, 8 parts of salad oil, 55 parts of eggs, and 1 part of table salt in parts by weight. , 1.6 parts of baking powder, 20 parts of water;

[0038] C. Preheating: put the weighed margarine and powdered sugar in a container, and preheat in an oven for 20 minutes. The oven temperature is set at 35°C;

[0039] D. Mixing: Beat the preheated margarine and powdered sugar until there are no obvious white powdered sugar particles, then add eggs and continue to beat until the surface starts to foam, then add salad oil, salt, foam Beat the powder and continue to beat until the surface foams and turns white to form the initial material for maki...

Embodiment 3

[0044] A. Raw material crushing: crush green tea and pinto bean respectively to make green tea powder and pinto bean powder, so that the particle size of both can reach more than 800 mesh;

[0045] B. Weighing: Weigh 100 parts of flour, 4.5 parts of green tea powder, 10 parts of flower bean powder, 60 parts of Maggie powder, 45 parts of powdered sugar, 10 parts of salad oil, 60 parts of eggs, and 1.3 parts of salt in parts by weight. , 1.8 parts of baking powder, 22 parts of water;

[0046] C. Preheating: put the weighed Maggiline and powdered sugar in a container, and put it in an oven to preheat for 25 minutes, and set the temperature of the oven at 35°C;

[0047] D. Mixing: Beat the preheated margarine and powdered sugar until there are no obvious white powdered sugar particles, then add eggs and continue to beat until the surface starts to foam, then add salad oil, salt, foam Beat the powder and continue to beat until the surface foams and turns white to form the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com