Shield machine synchronous grouting pipeline system and shield machine with same

A technology of synchronous grouting and pipeline system, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of insufficient flushing, blockage of synchronous grouting pipeline system, inconvenient cleaning, etc., so as to shorten the maintenance time. , the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

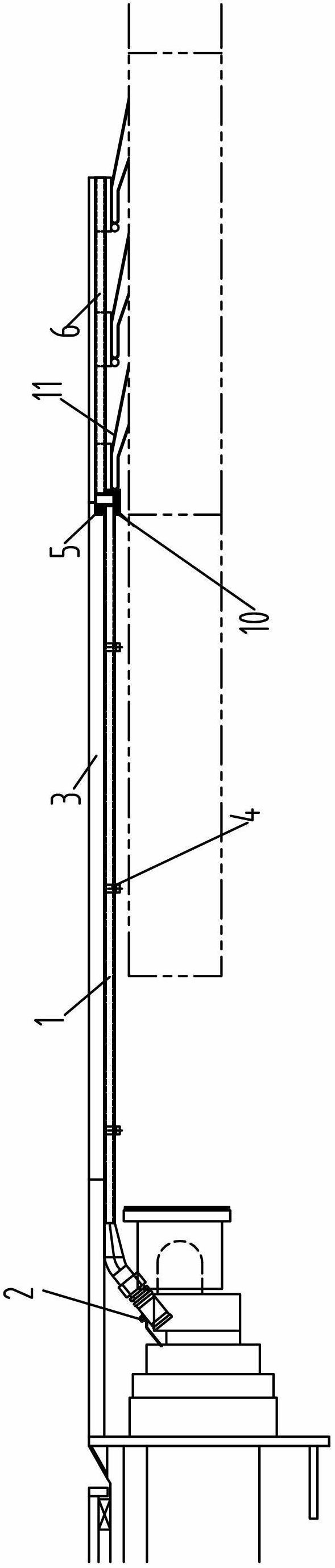

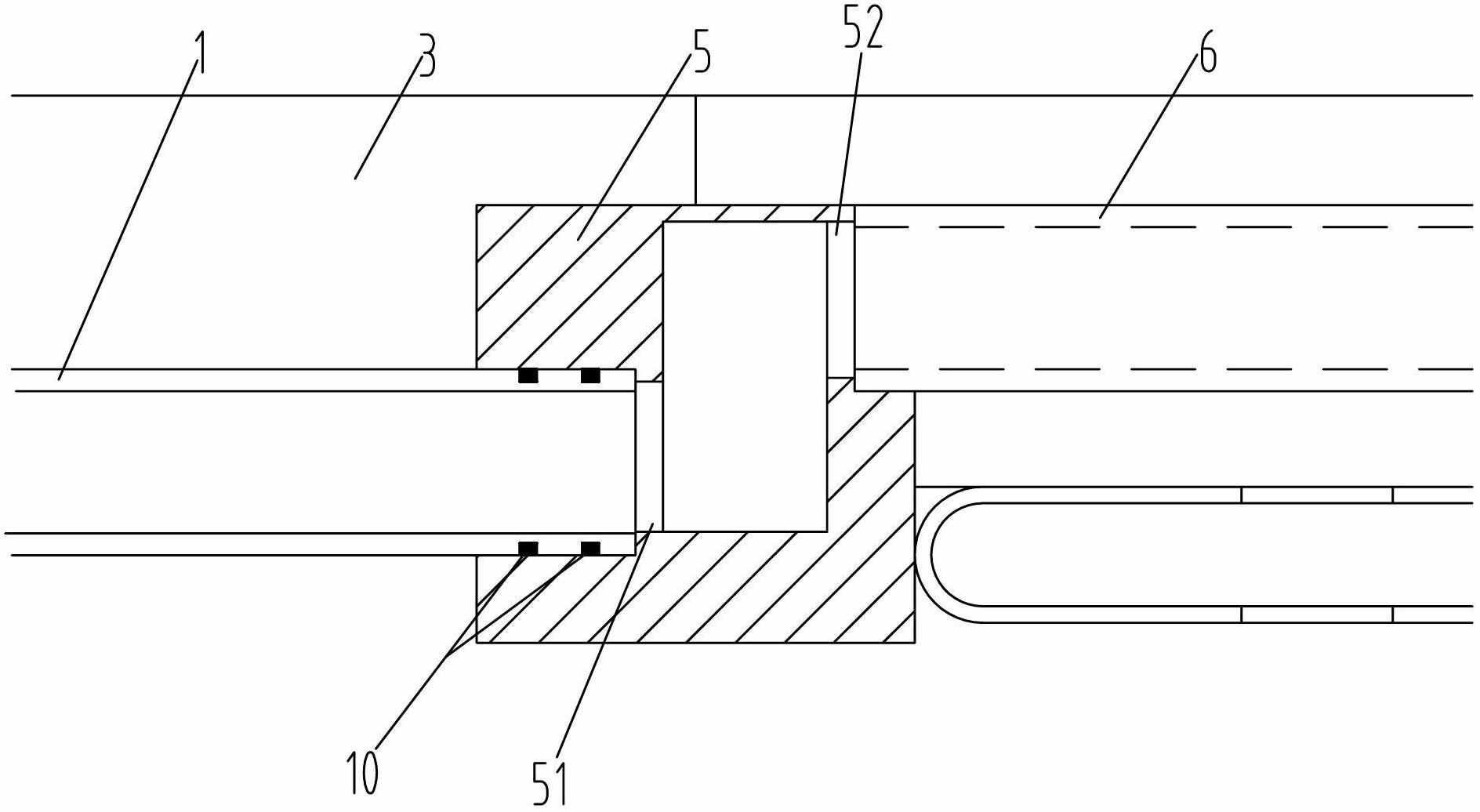

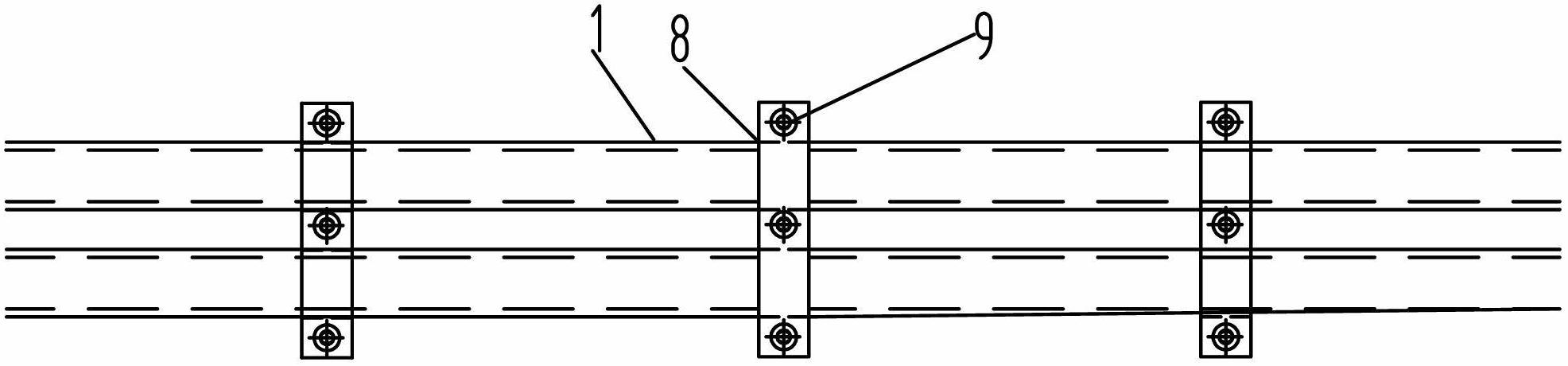

[0025] see figure 1 and figure 2 , the embodiment of the present invention provides a shield machine synchronous grouting pipeline system, the system includes: several grouting pipelines, each grouting pipeline includes a first grouting pipe 1, and a first grouting pipe A gate valve 2 detachably connected to one end of 1, a fixed structure 4 for detachably installing the first grouting pipe 1 on the inner wall of the shield tail 3, a transition block 5 arranged on the inner wall of the shield tail 4, and the second grouting The two ends of the pipe 6 and the transition block 5 are respectively provided with a first connecting hole 51 and a second connecting hole 52, the first connecting hole 51 and the second connecting hole 52 communicate with each other, the other end of the first grouting pipe 1 is connected to the first The connecting hole 51 is detachably connected, and one end of the second grouting pipe 6 is connected to the second connecting hole 52 , and the second ...

Embodiment 2

[0038]An embodiment of the present invention provides a shield machine, including a shield machine body and a synchronous grouting pipeline system installed in Embodiment 1 of the shield machine body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com