Multilevel multi-curve single-layer welding ball steel structure net rack and construction method thereof

A multi-surface, multi-level technology, applied in building components, building structures, roofs, etc., to achieve the effects of convenient adjustment, reasonable structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

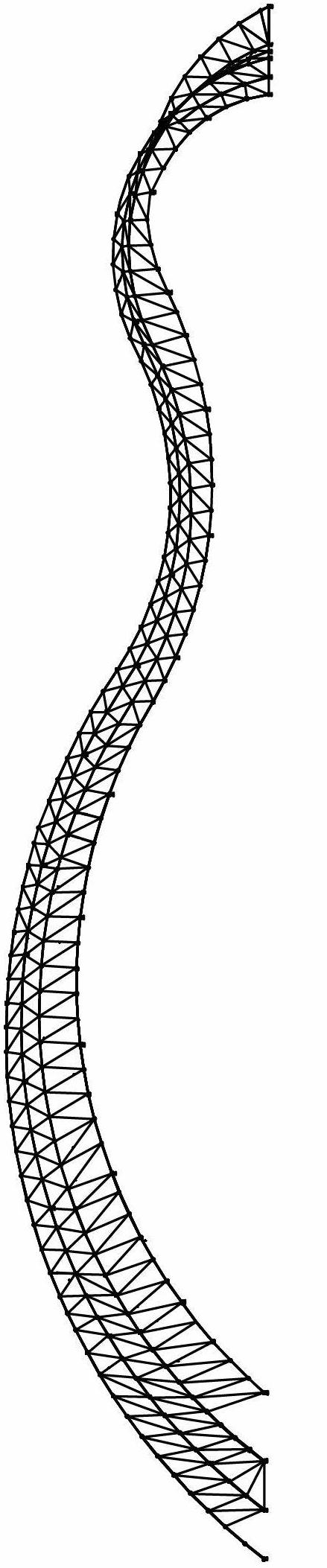

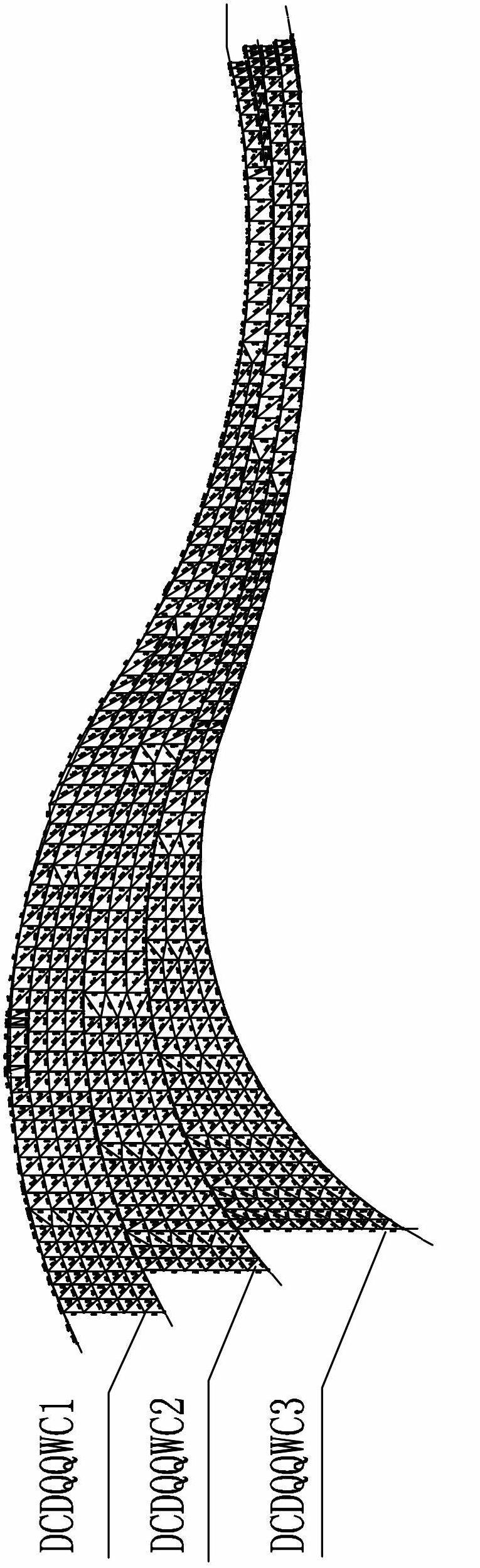

[0091] Embodiment 1: A multi-level multi-curved surface single-layer welded spherical steel structure grid.

[0092] It consists of a multi-layer single-layer multi-curved single-layer welded spherical steel structure grid and a column of reinforced concrete structure supporting the single-layer multi-curved single-layer welded spherical steel structure grid, a multi-curved single-layer welded spherical steel structure with 3 layers Structural grid such as figure 1 As shown, each of its single-layer multi-curved surface single-layer welded spherical steel structure grids is composed of separate structural rods III, hollow balls II, and elastic bearings I connected into one body by welding; The elastic support Ⅰ on the top is connected with the single-layer multi-curved single-layer welded spherical steel structure grid through the grid support rod IV.

[0093] As a multi-curved single-layer welded spherical steel structure grid, the rod III is made of steel pipes of differen...

Embodiment 2

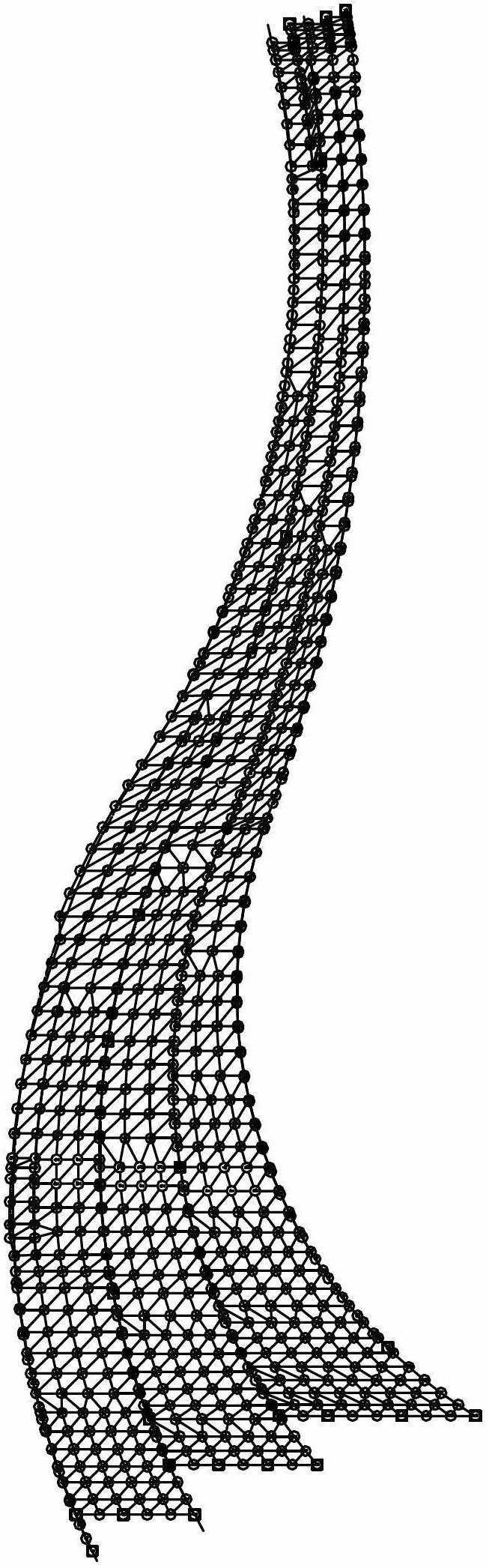

[0110] Embodiment 2: A multi-level multi-curved surface single-layer welded spherical steel structure grid with a suspensive structure.

[0111] For the multi-level multi-curved single-layer welded spherical steel structure grid with a relatively large span, in order to ensure the stability of its structure, the stability can be guaranteed by adding a string support structure. Figure 11 As shown, it is a multi-level and multi-curved single-layer welded spherical steel structure grid with 3 sets of string structures. Each string structure includes string structure support X, string ball XI, cable XII and string ball support Rod XIII (see Figure 12 );

[0112] The suspension structure support X includes a suspension structure support ball 101 and a cover plate 102, and the suspension structure support ball 101 is mounted on a multi-level multi-curved single-layer welded spherical steel structure grid Hollow ball, selected according to design requirements (see Figure 11 ), ...

Embodiment 3

[0117] Embodiment 3: A construction method of a multi-layered multi-curved single-layer welded spherical steel structure grid.

[0118] The method is carried out on site by adopting the separated structure of the multi-level multi-curved surface single-layer welded steel space steel grid structure described in the first embodiment of the present invention, the rod element III, the hollow spherical element II, the elastic support I and the grid support rod IV. The method of single-layer welding and assembling into a multi-layer and multi-curved single-layer welded spherical steel structure grid. For each single-layer multi-curved single-layer welded spherical steel structure grid, generally a single-layer multi-curved single-layer in the middle is installed first. Weld the spherical steel structure grid, and then install the surrounding grid; it includes the following specific steps:

[0119] A. Production of the first single-layer multi-curved single-layer welded spherical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com