Environment-friendly efficient bubble-free cleaning agent

A cleaning agent and high-efficiency technology, applied in the field of cleaning agents, can solve the problems of reducing production and processing efficiency and cost, threatening the safety and health of workers, and insufficient rust and corrosion resistance, so as to improve production efficiency and eliminate rust and corrosion. Process, the effect of ensuring good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

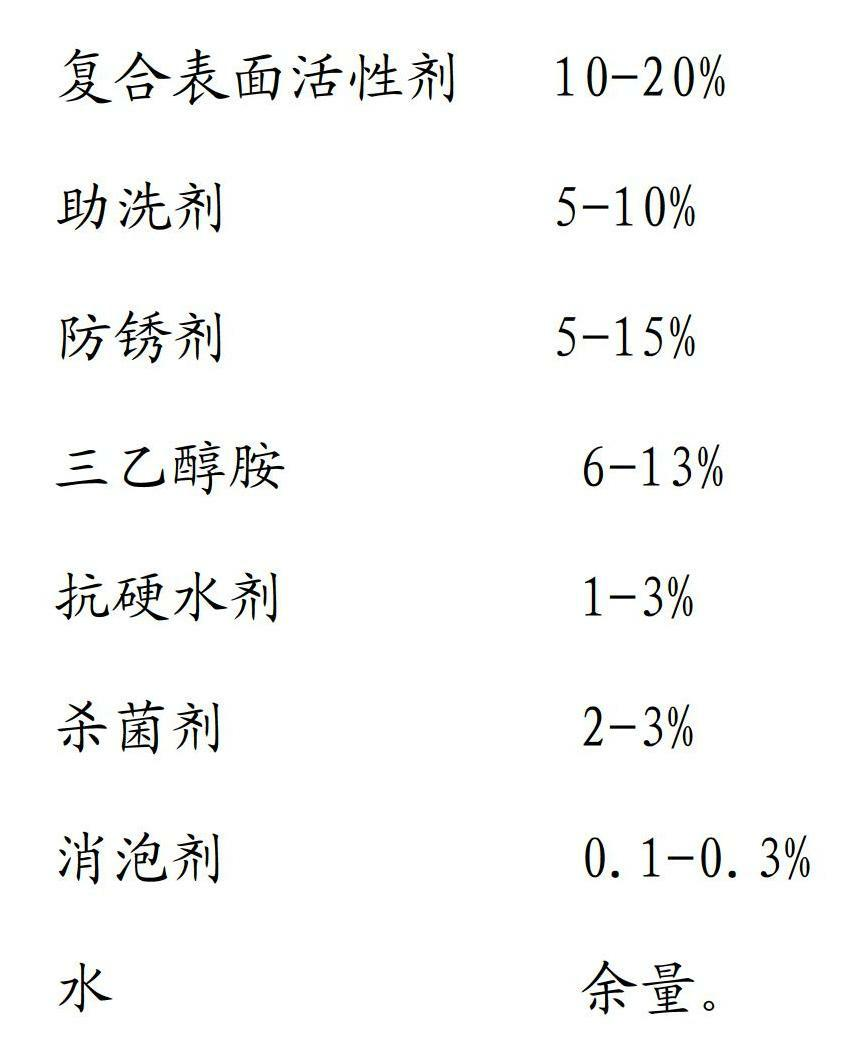

Method used

Image

Examples

Embodiment 1

[0016] The environmentally friendly and efficient non-foaming cleaning agent of the present invention is configured with green additives, and the weight components are as follows: 10% of composite surfactant fatty alcohol polyoxyethylene ether, 10% of builder sodium carbonate, 8% of antirust agent amide, Triethanolamine 10%, anti-hard water agent ether carboxylic acid 1%, fungicide morpholine 2%, defoamer polyether 0.1%, and the balance is water.

[0017] The preparation method and steps are as follows:

[0018] First, calculate the quality of water required based on the total amount of cleaning agent required. In a blending kettle filled with water of this quality, under normal temperature conditions, add fatty alcohol polyoxyethylene ether, sodium carbonate, and amide into water in sequence, stir and dissolve completely, then add triethanolamine, ether carboxylic acid, morpholine and Stir the polyether in water until it is completely transparent.

Embodiment 2

[0020] The environmentally friendly and efficient non-foaming cleaning agent of the present invention is configured with green additives, and the weight components are as follows: 15% of the composite surfactant fatty acid alkanolamide (6501, Ninar), 8% of the builder sodium silicate, and Rust agent amide 15%, triethanolamine 10%, anti-hard water agent EDTA-2Na 1%, fungicide hexahydrotriazine 2%, defoamer acrylate 0.1%, and the balance is water.

[0021] The preparation method and steps are as follows:

[0022] First, calculate the quality of water required based on the total amount of cleaning agent required. In a blending kettle filled with water of this quality, under normal temperature conditions, add fatty acid alkanolamide, sodium silicate, and amide in proportion to water in sequence, stir and dissolve completely, then add triethanolamine, EDTA-2Na, hexahydrotrimonium chloride Oxyzine and acrylate are stirred in water until completely transparent.

Embodiment 3

[0024] The environmentally friendly and efficient non-foaming cleaning agent of the present invention is configured with green additives, and its weight components are as follows: 20% of complex surfactant fatty acid alkanolamide (6501, Ninar), 5% of builder sodium sulfate, antirust The agent is sorbitol monooleate 12%, triethanolamine 6%, anti-hard water agent EDTA-2Na 3%, fungicide hexahydrotriazine 2.5%, defoamer acrylate 0.2%, and the balance is water.

[0025] The preparation method and steps are as follows:

[0026] First, calculate the quality of water required based on the total amount of cleaning agent required. In a blending kettle filled with water of this quality, under normal temperature conditions, add fatty acid alkanolamide, sodium sulfate, and sorbitan monooleate into water in sequence, stir and dissolve completely, then add triethanolamine, EDTA- 2Na, hexahydrotriazine and acrylate are stirred in water until completely transparent, that is, too.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com