Process and equipment for converting carbon dioxide in flue gas into natural gas by using dump power energy

A technology of carbon dioxide and natural gas, applied in the field of natural gas, can solve problems such as grid-connected barriers for renewable energy power generation, difficulty in storing short-term surpluses, and environmental pollution caused by greenhouse gases in fossil energy power generation, achieving huge economic and social benefits, improving conversion efficiency, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

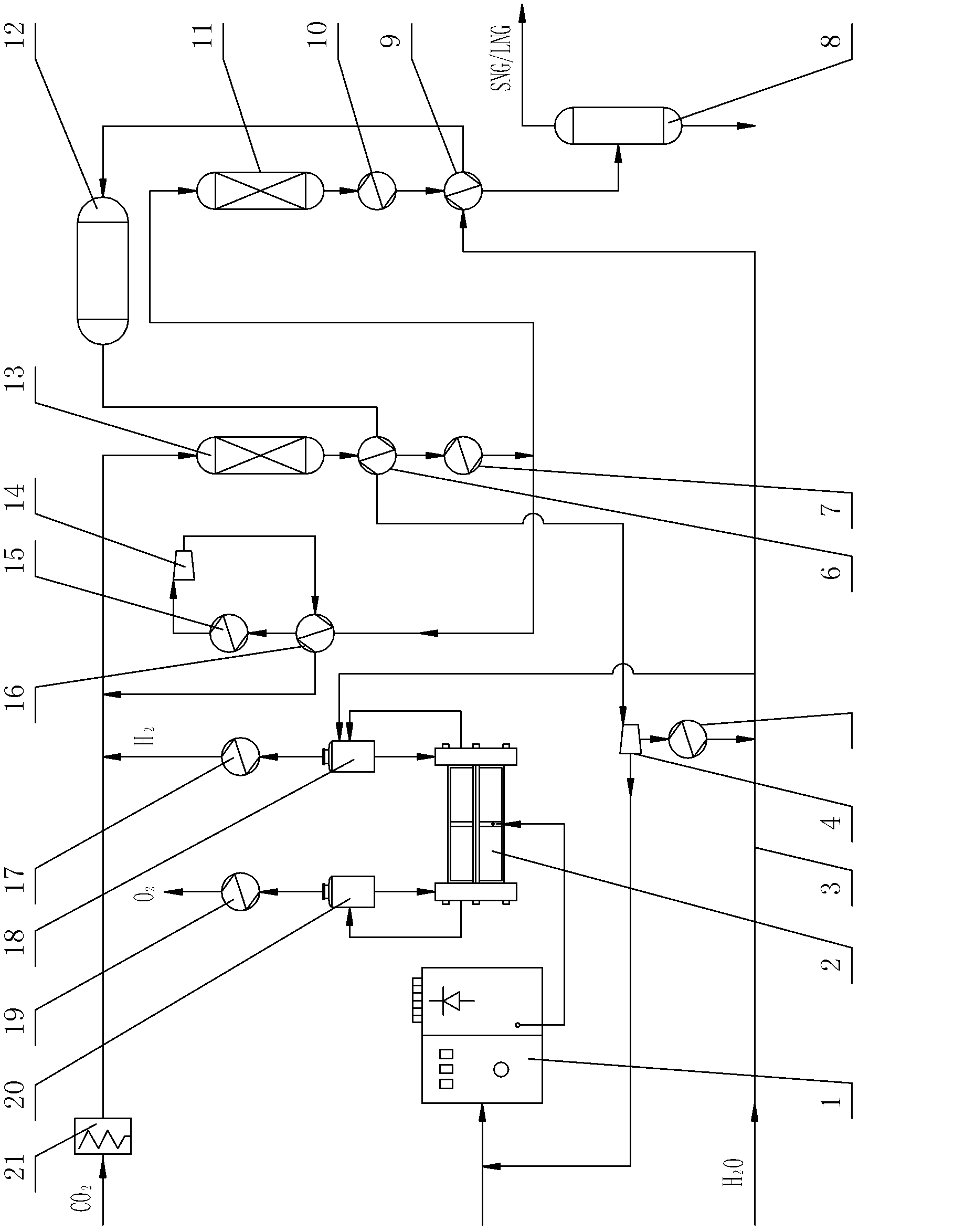

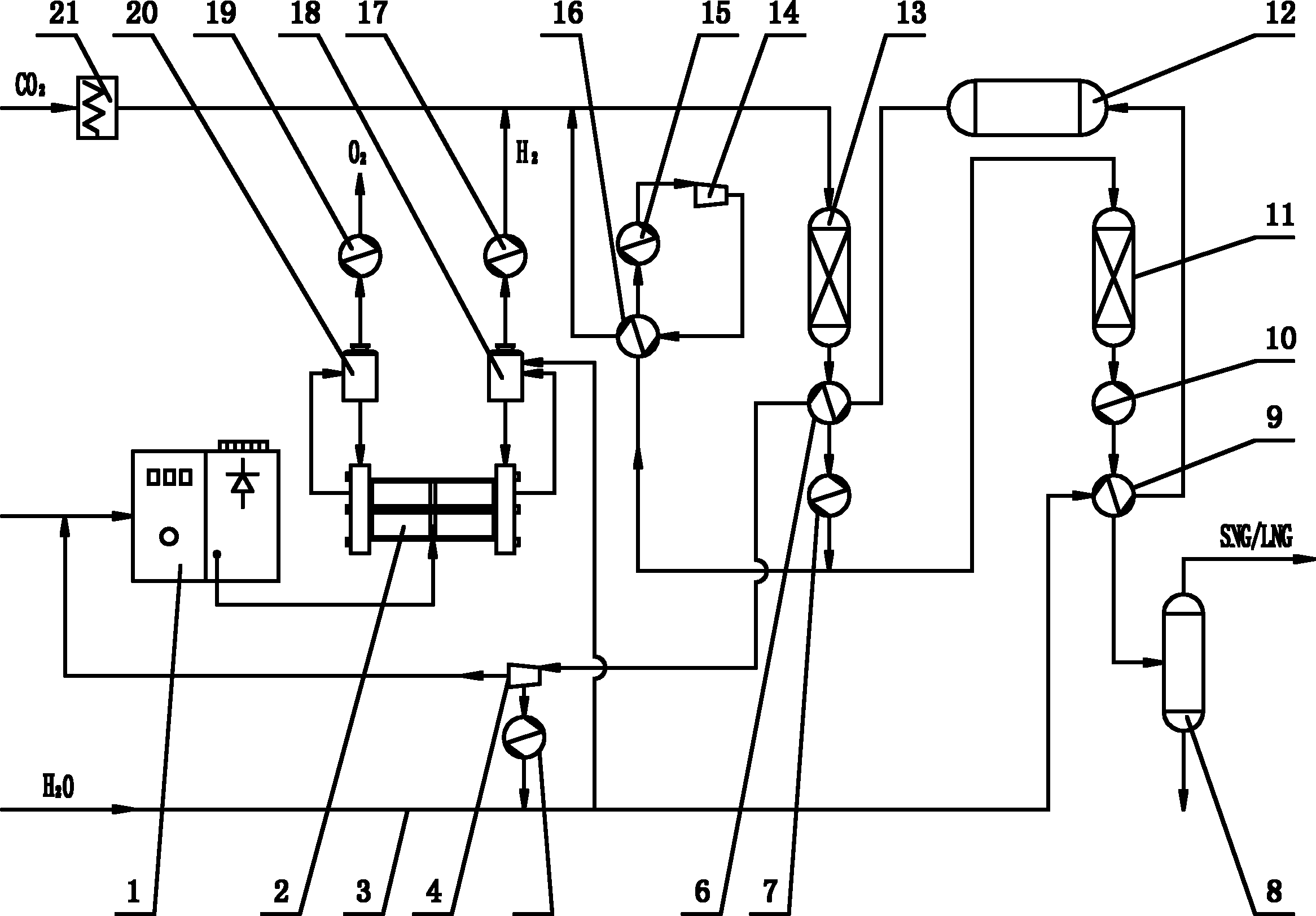

[0036] Embodiment 1: as figure 1 The shown equipment for converting carbon dioxide into natural gas by using excess electric energy is mainly composed of a voltage transformation and rectification device 1, an electrolytic cell 2, a turbo generator 4, a carbon dioxide heater 21, a first-stage fixed-bed reactor 13, and a second-stage fixed-bed reactor. The secondary fixed bed reactor 11, the natural gas condenser 8 and the process water pipeline 3 are composed of components. The output end of the transformer and rectifier device 1 is connected to the power interface of the electrolytic cell 2 . The anode gas-liquid outlet of the electrolytic cell 2 is connected with the gas-liquid input end of the oxygen separator 20, and the liquid output end of the oxygen separator 20 is connected with the anode liquid return port of the electrolytic cell 2, and the O of the oxygen separator 20 2 The output end links to each other with the inlet of oxygen cooler 19, and the outlet of oxygen ...

Embodiment 2

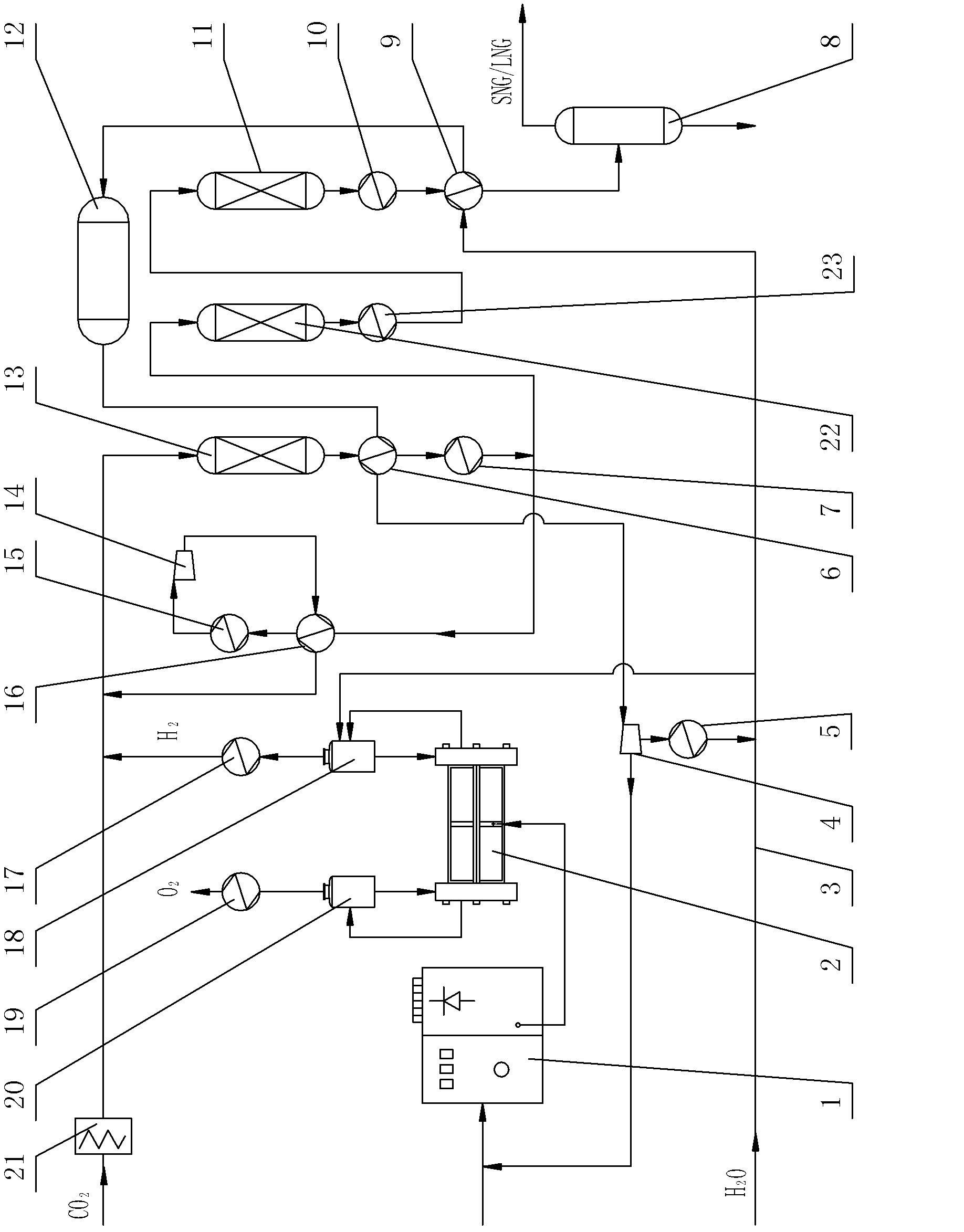

[0044] Embodiment 2: as figure 2 Another shown equipment for converting carbon dioxide into natural gas by using excess electric energy has the same structure and process flow as in Example 1, except that the first-stage fixed-bed reactor 13 and the second-stage fixed-bed reactor 11 are located between An intermediate fixed bed reactor 22 is also provided, the inlet of the intermediate fixed bed reactor 22 is connected with the mixed gas output end of the primary heat exchanger 7, and the outlet of the intermediate fixed bed reactor 22 is connected with the second stage through the intermediate heat exchanger 23. The inlets of the fixed bed reactor 11 are connected. In this way, a three-stage fixed-bed reactor is provided, and H can be distributed in three stages. 2 with CO 2The methanation reaction rate ensures complete reaction of raw materials. At the same time, the temperature at the inlet and outlet of the three-stage fixed-bed reactor can be lowered successively to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com