Core-shell TiO2-BiOCl heterojunction photocatalyst with large specific surface area and preparation method thereof

A technology with large specific surface area and photocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex process, small specific surface area of materials, and high preparation cost, and achieve a simple method and process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

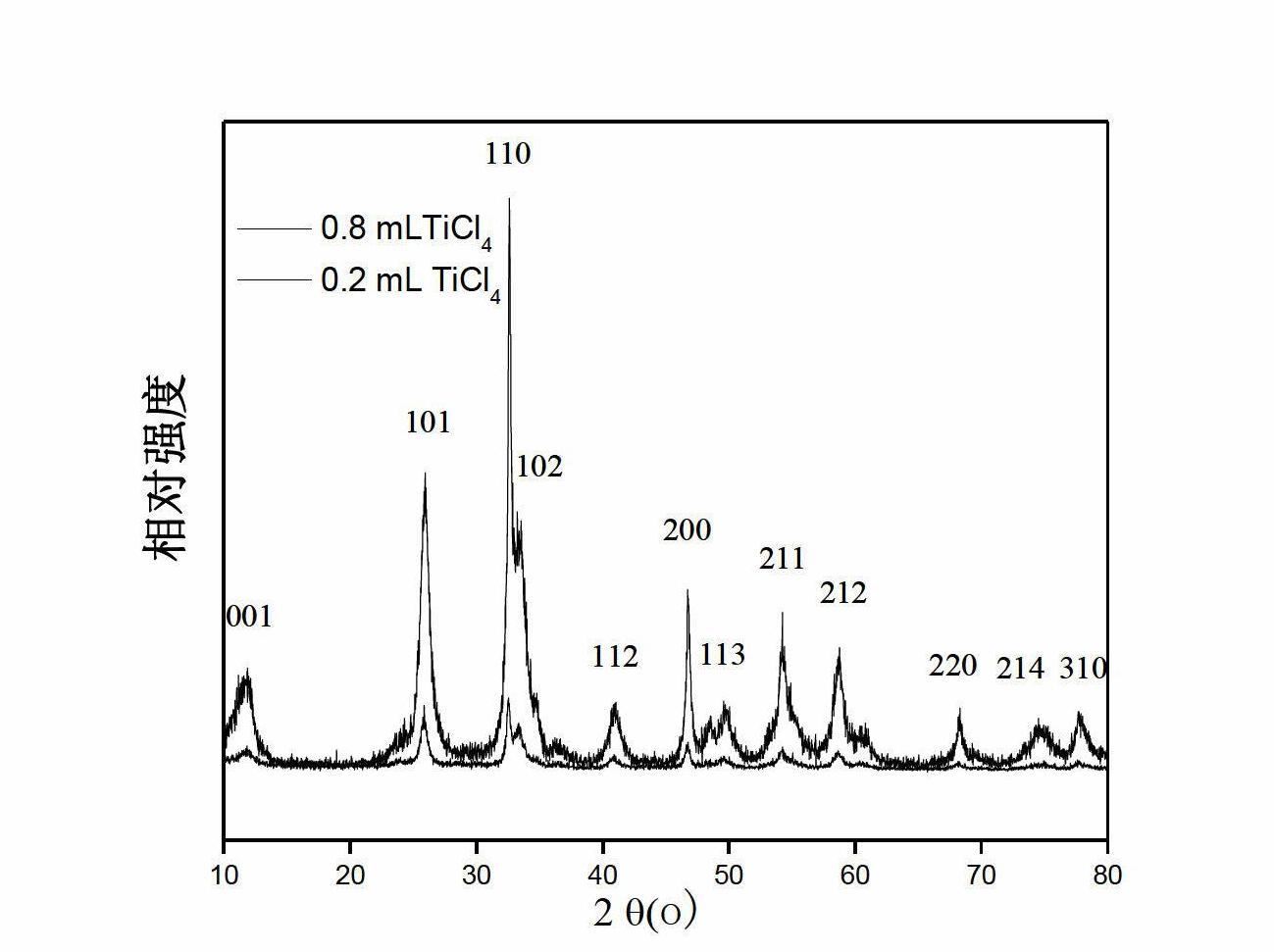

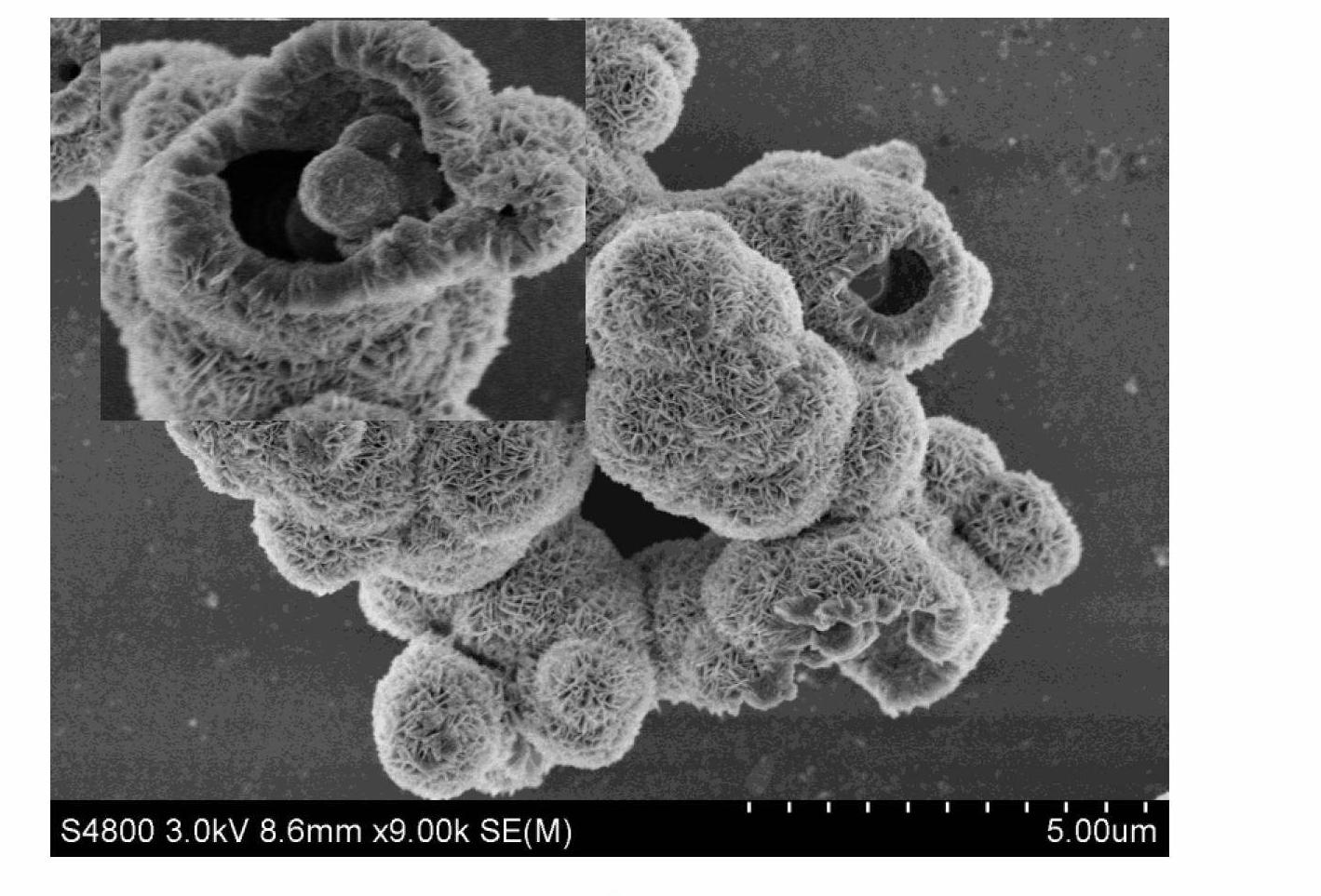

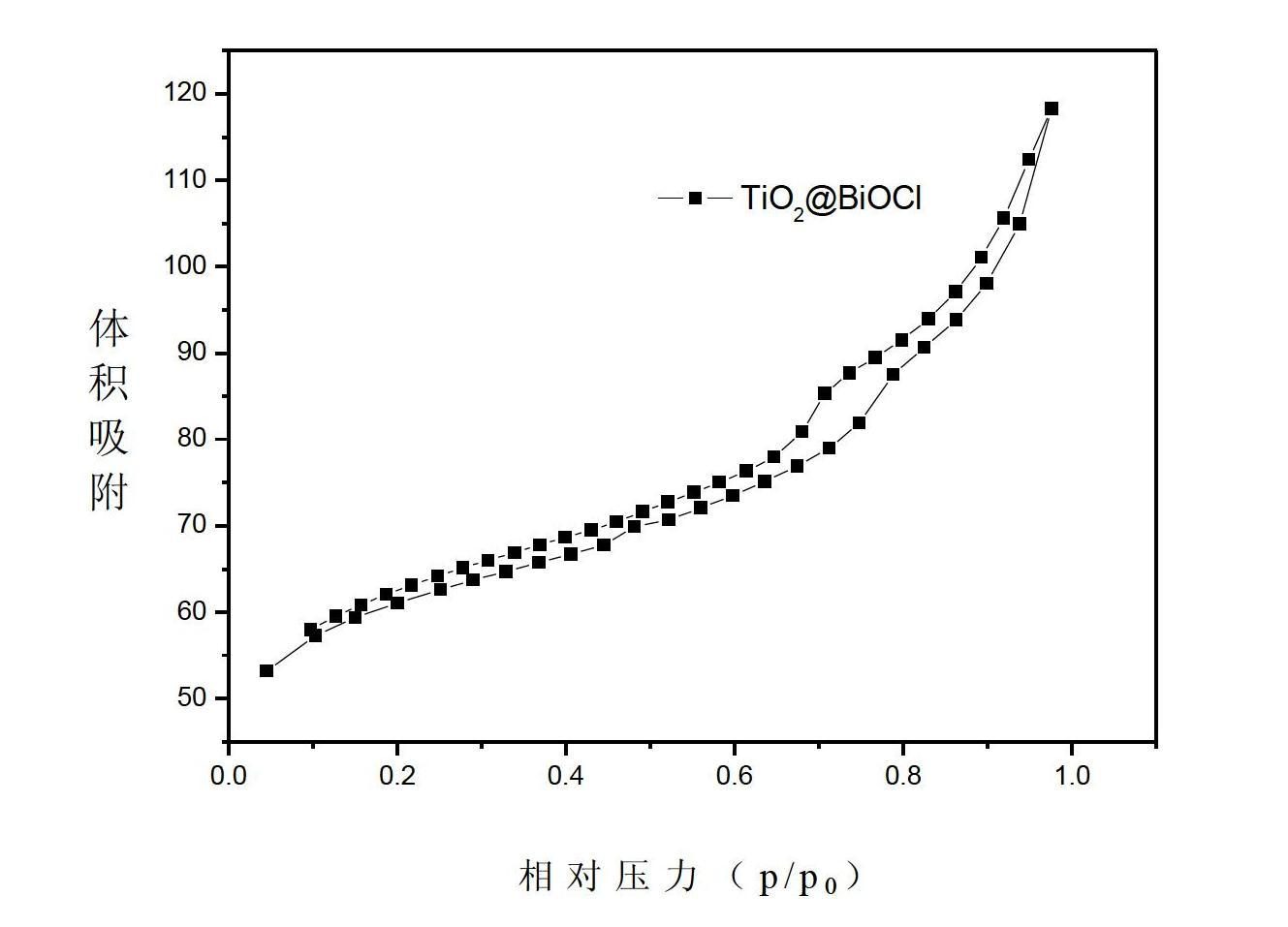

Embodiment 1

[0024] Get 5mL glycerol and add in 25mL ethanol solution, and after stirring evenly, add 3.37g Bi(NO 3 ) 3 ·5H 2 O, then stirred until clear. Place the solution in an ice-water bath system and add 0.6mL TiCl 4 , stirred until clarified and put into a 50mL hydrothermal kettle at 110°C, kept for 72h and then cooled to room temperature naturally. After centrifugation and washing with deionized water and ethanol three times each, vacuum drying at 80 °C for 12 h yielded a large specific surface area core-shell TiO 2 -BiOCl heterojunction photocatalyst.

Embodiment 2

[0026] Take 10mL of glycerol and add it into 20mL of ethanol solution, and after stirring evenly, add 3.37g of Bi(NO 3 ) 3 ·5H 2 O, then stirred until clear. Place the solution in an ice-water bath system and add 0.6mL TiCl 4 , stirred until clarified and put into a 50mL hydrothermal kettle, kept at 180°C for 12 hours, and then naturally cooled to room temperature. After centrifugation and washing with deionized water and ethanol three times each, vacuum drying at 80 °C for 12 h yielded a large specific surface area core-shell TiO 2 -BiOCl heterojunction photocatalyst.

Embodiment 3

[0028] Take 10mL of glycerol and add it into 20mL of ethanol solution, and after stirring evenly, add 3.37g of Bi(NO 3 ) 3 ·5H 2 O, then stirred until clear. Place the solution in an ice-water bath system and add 0.4mL TiCl 4 , stirred until clarified and charged into 50mL in a 150°C hydrothermal kettle for 36h, then cooled naturally to room temperature. After centrifugation and washing with deionized water and ethanol three times each, vacuum drying at 80 °C for 12 h yielded a large specific surface area core-shell TiO 2 -BiOCl heterojunction photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com