Rotary positioning and pulse back-blowing bag type dust remover and dust removing method thereof

A bag-type dust collector and dust removal technology, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of weak dust removal ability, improve dust removal ability, increase service life, and make up for the dust removal effect uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

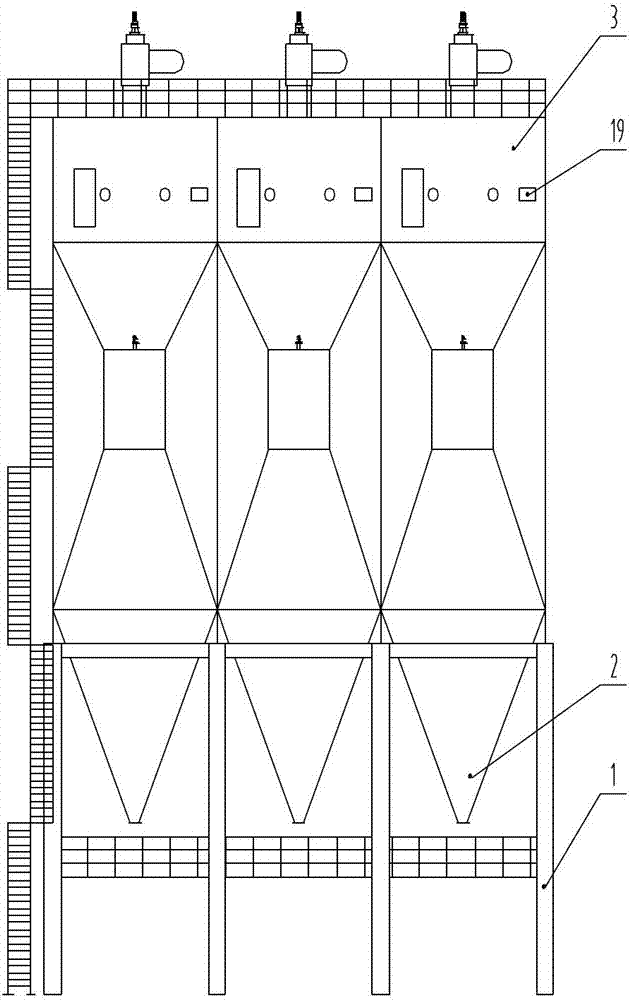

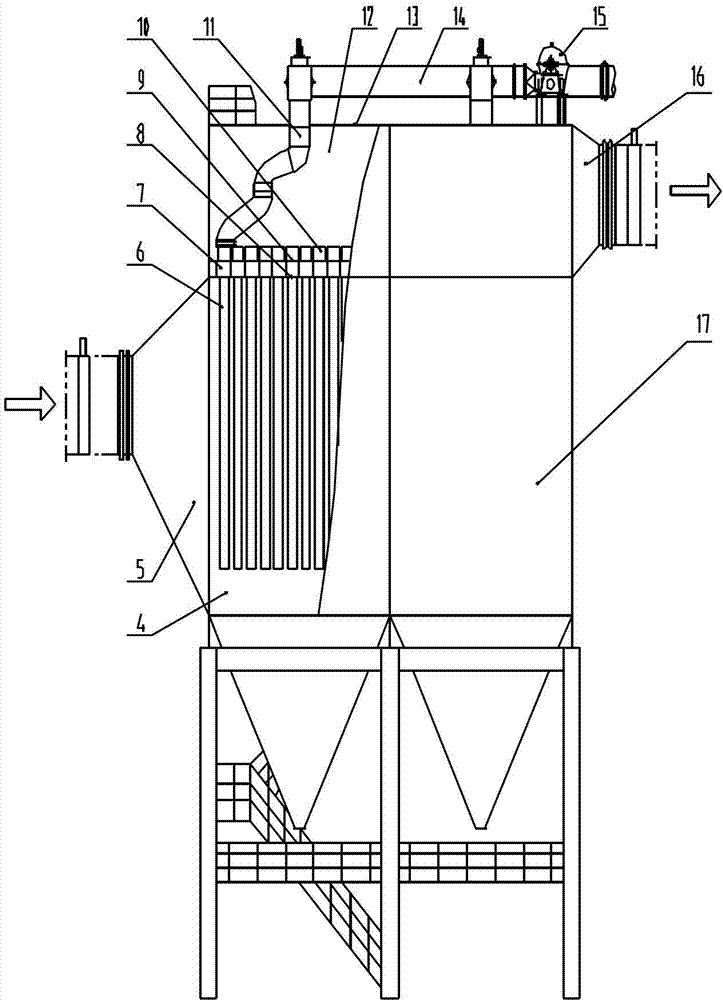

[0033] The present invention is a rotary positioning pulsating back-blowing bag type dust collector, which has the characteristics of strong dust cleaning ability, long service life of the filter bag, low equipment cost and reliable operation, such as figure 1 , figure 2 , image 3 As shown, the rotary positioning pulsation blowback bag filter is composed of several dust removal channels 3 connected in parallel.

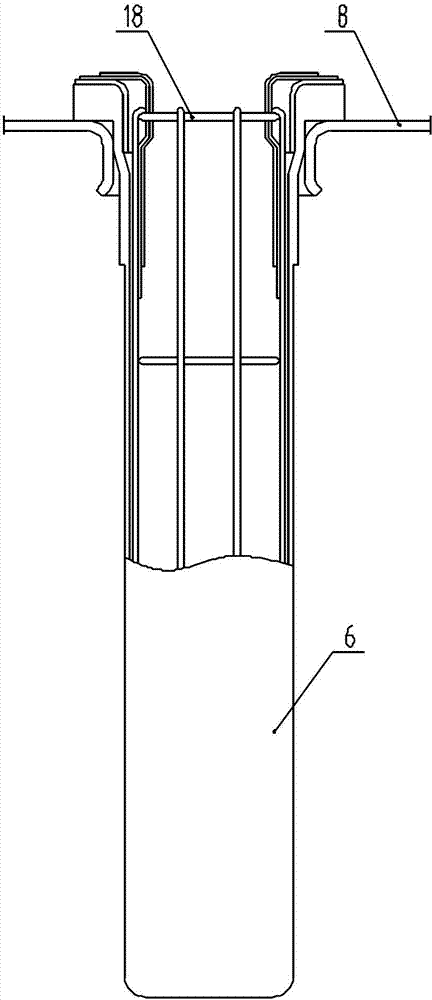

[0034] The dust removal channel 3 includes a bracket 1, a dust collecting bucket 2, a blowback air box 7, a housing 17, an intake smoke box 5, a filter bag 6, a blowback air box 7, a flower plate 8, a box cover 9, and a flow guide Cover 10, rotary positioning pulsation back blowing dust cleaning mechanism 11, top cover 13, booster fan 15, gas outlet smoke box 16, housing 17, bag cage 18 and control system 19.

[0035] The lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com