Natural crack button and preparation method thereof

A technology of natural cracks and buttons, applied in the field of buttons, can solve the problems of lack of realism and three-dimensional sense, chromatic aberration of cracked buttons, and inability to present crack effects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

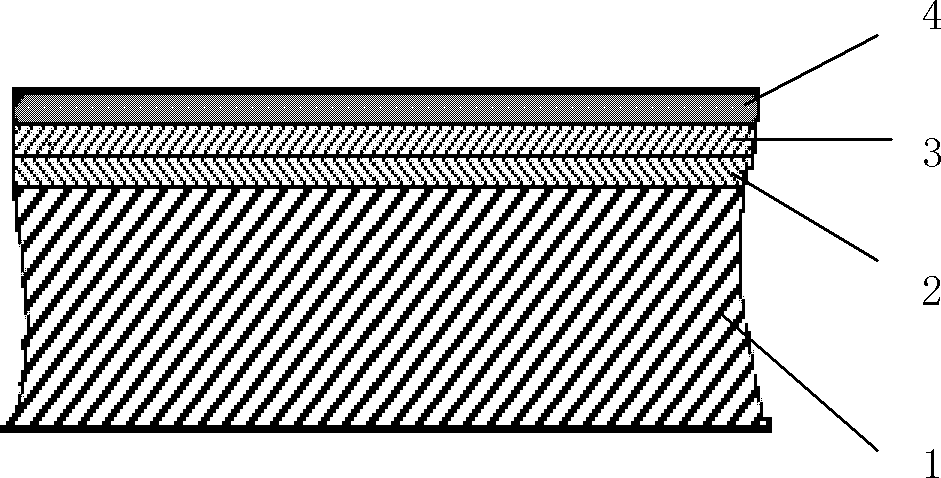

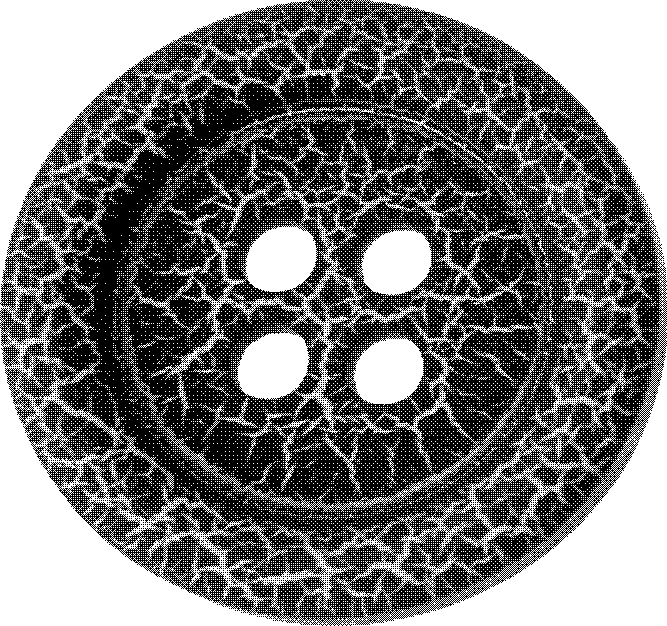

[0035] A matte button with a black button blank itself and black cracks and white cracks, which comprises a prepared black unsaturated resin button blank 1 and a white primer layer 2, a black crack layer 3, Clear matte finish coat 4 (see Figure 1-2 ).

[0036] The preparation method is as follows:

[0037] (1) Button embryo treatment: Put 24L round black unsaturated resin button embryos into water according to the conventional method for 4 hours and then arrange them;

[0038] (2) Primer: Dilute 1 part of white nitro lacquer containing 10% alkyd resin and 5% nitrocellulose and 1 to 1.5 parts of nitro lacquer thinner in proportion (parts by weight). The viscosity is controlled at 12 to 13 seconds, the air pressure of the sprayer is adjusted to 0.3MPa, the injection flow rate is 150ml / min, the angle between the nozzle and the surface to be sprayed is adjusted to 75 degrees, the distance between the nozzle and the surface to be sprayed is 20cm, and the spray angle Spray on th...

Embodiment 2

[0042] A kind of bright button blank which is red in itself and has white crack spots and yellow cracks. It consists of a red unsaturated resin button blank that has been prepared, and a yellow primer layer, a white crack layer, and a transparent matte topcoat layer are sprayed on the button blank in sequence.

[0043] The preparation method is as follows:

[0044] (1) Button embryo treatment: put 24L round red unsaturated resin button embryos into water according to the conventional method for 4 hours and then arrange them;

[0045] (2) Primer: Dilute 1 part of yellow nitro lacquer containing 10% alkyd resin and 5% nitrocellulose and 1 to 1.5 parts of nitro lacquer thinner in proportion (parts by weight). The viscosity is controlled between 12 and 13 seconds, the air pressure of the sprayer is adjusted to 0.3MPa, the oil injection flow rate is 150ml / min, the angle between the nozzle and the surface to be sprayed is adjusted to 75 degrees, and the distance between the nozzle ...

Embodiment 3

[0049] A five-point button with black cracks in coppery splotches. It includes the unsaturated resin button blank that has been prepared and sprayed on the button blank in sequence with a black primer layer, a copper-colored crack layer, and a transparent five-splitting topcoat layer.

[0050] The preparation method is as follows:

[0051] (1) Button blank treatment: grind 30L round unsaturated resin button blank in water for 4 hours and place it;

[0052] (2) Primer: Dilute 1 part of black nitro lacquer containing 10% alkyd resin and 5% nitrocellulose and 1 to 1.5 parts of nitro lacquer thinner in proportion (parts by weight). The viscosity is controlled between 12 and 13 seconds, the air pressure of the sprayer is adjusted to 0.3MPa, the oil injection flow rate is 150ml / min, the angle between the nozzle and the surface to be sprayed is adjusted to 75 degrees, and the distance between the nozzle and the surface to be sprayed is 20cm. The width angle is between 60 and 150 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com