Target and backing plate assembly

A backing plate and assembly technology, applied in ion implantation plating, coating, electrical components, etc., can solve the problems of high target use efficiency, arcing, and large changes in film forming speed, and achieve the generation of powder particles. Less, high efficiency, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

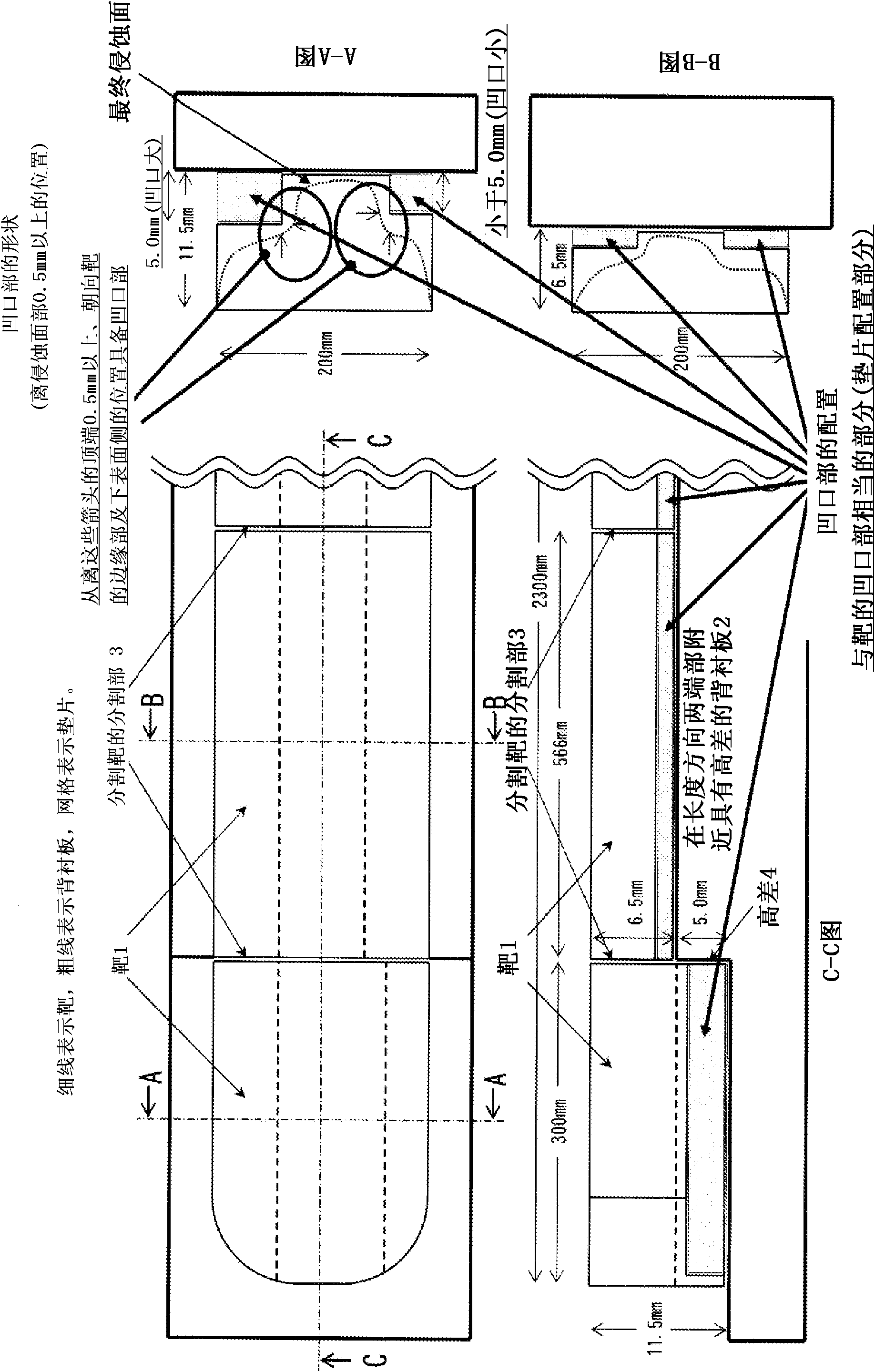

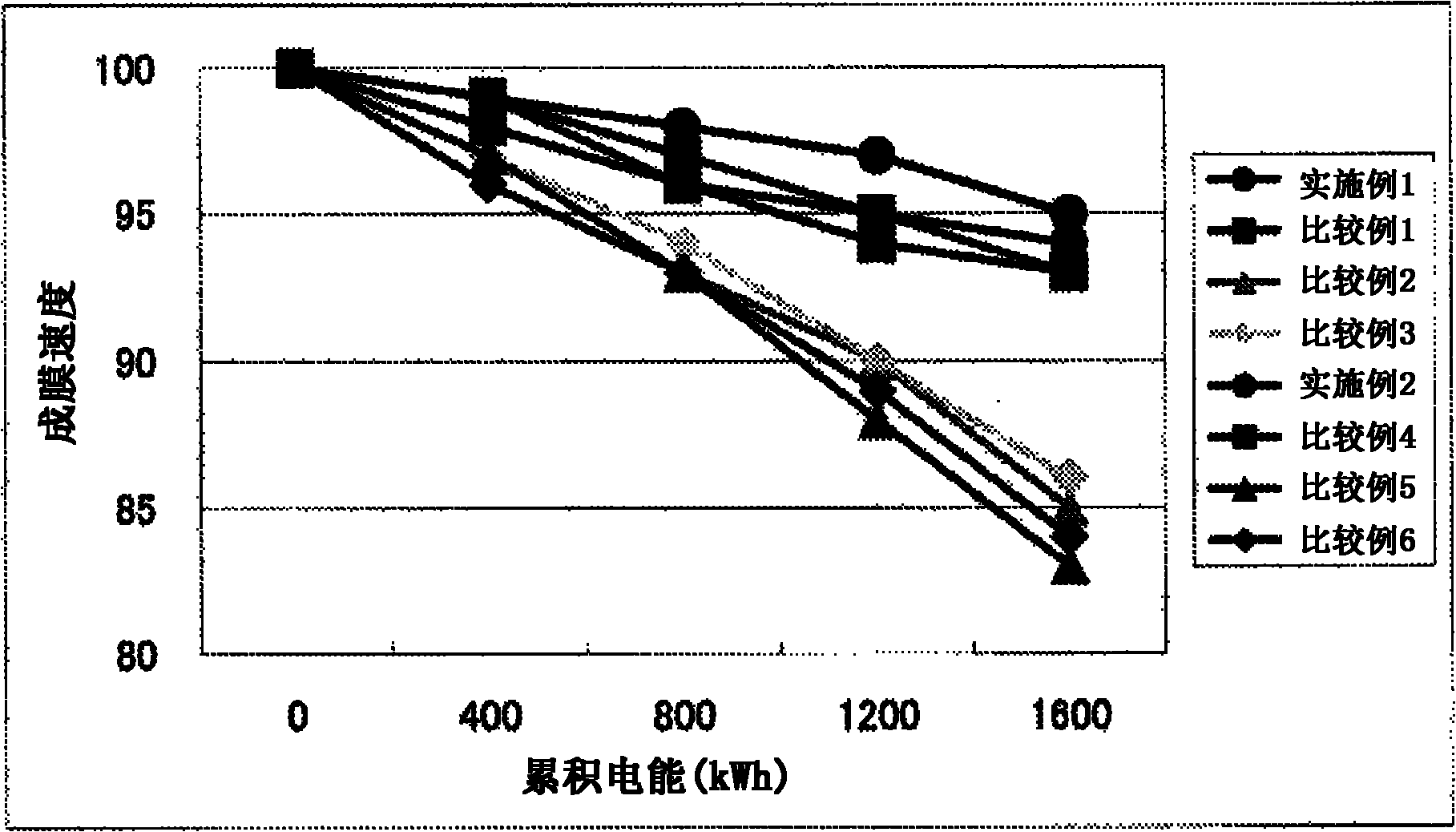

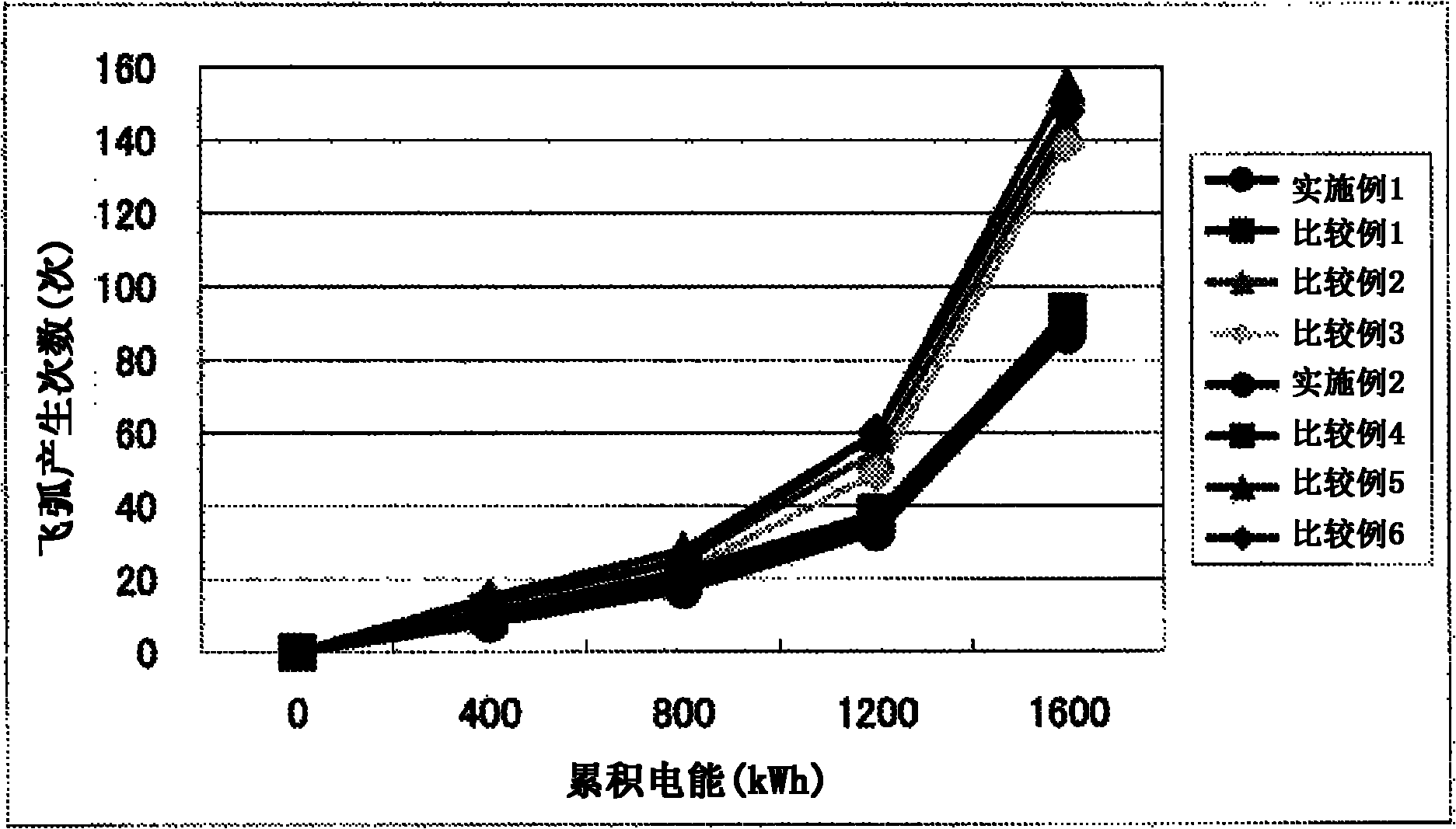

[0079] use figure 1 In the shown copper backing plate and target, ITO (indium tin oxide) was used as the target. figure 1 A plan view (part), C-C sectional view, A-A sectional view, and B-B sectional view of the target-backing plate assembly are shown. as it should figure 1 As shown, the backing plate of the target-backing plate assembly of Example 1 is rectangular (rectangular) in plan view, and both ends in the longitudinal direction of the target are elliptical. In this case, a split target is used. The bottoms of both sides in the longitudinal direction of this divided target are left-right asymmetrical in the longitudinal direction.

[0080] As for the backing board, a backing board having a thickness of 5.0 mm on both sides in the longitudinal direction, that is, a backing board having a height difference of 5.0 mm was used. Copper spacers with a thickness of 4.5 mm and a thickness of 5.0 mm were placed on the height difference portion, that is, the thin side of t...

Embodiment 2

[0126] use Figure 8 In the shown copper backing plate and target, ITO (indium tin oxide) was used as the target. Figure 8 A plan view (part), C-C sectional view, A-A sectional view, and B-B sectional view of the target-backing plate assembly are shown. as it should Figure 8 As shown, the backing plate of the target-backing plate assembly of Example 2 is rectangular (rectangular) in plan view, and both ends in the longitudinal direction of the target are elliptical. In this case, a split target is used. The bottoms of both sides in the longitudinal direction of this split target are asymmetrical in the longitudinal direction (concavo-convex shape) similarly to Example 1. As the backing board, a backing board whose entire surface is flat is used.

[0127] And, as the targets on both sides in the longitudinal direction, those having notches of 4.5 mm and 5.0 mm on the side of the backing plate were used. Then, spacers made of copper with a thickness of 4.5 mm and a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com