Attachment for substrates having different diameters, substrate processing apparatus, and method of manufacturing substrate or semiconductor device

A technology for substrate processing devices and accessories, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

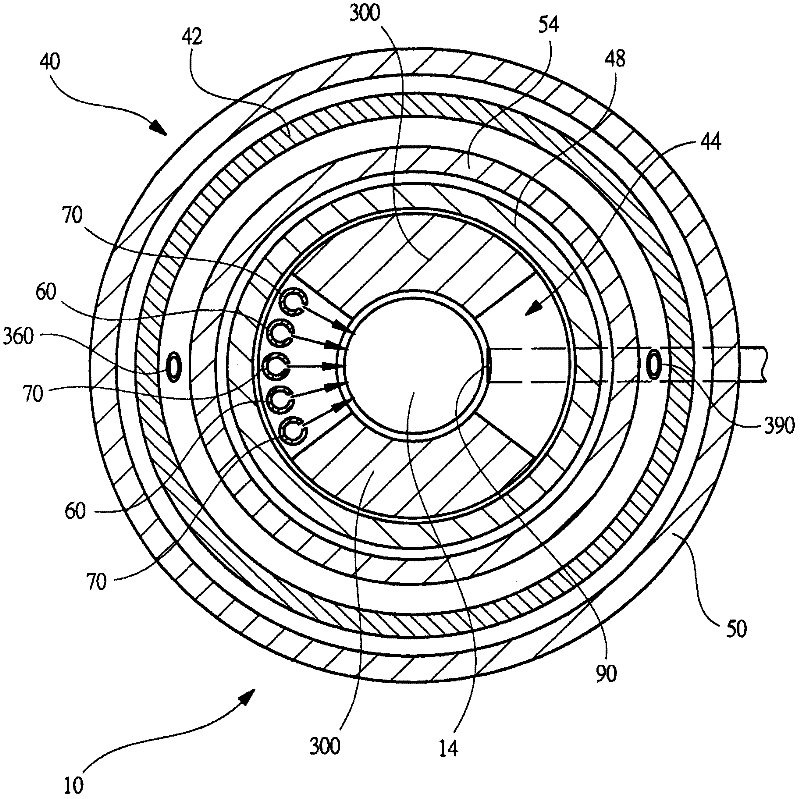

[0037] Next, a first embodiment of the present invention will be described in detail with reference to the drawings. In the following embodiments, a so-called batch-type vertical SiC epitaxial growth device that stacks SiC wafers in the height direction (vertical direction) is exemplified as a SiC epitaxial growth device that is an example of a substrate processing device. Thus, productivity (manufacturing efficiency) is improved by increasing the number of SiC wafers that can be processed at one time.

[0038]

[0039] figure 1 It is a perspective view showing the outline of a substrate processing apparatus using the attachment for substrates with different diameters of the present invention. First, use figure 1 A substrate processing apparatus for forming an SiC epitaxial film and a substrate manufacturing method for forming an SiC epitaxial film as one of the manufacturing steps of a semiconductor device according to an embodiment of the present invention will be describ...

no. 2 approach

[0155] Next, a second embodiment of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the part which has the same function as 1st Embodiment mentioned above, and the detailed description is abbreviate|omitted.

[0156] Figure 14 (a), (b) and Figure 13 The corresponding figure is shown.

[0157] like Figure 14 As shown in (a), the difference of the attachment 500 for substrates with different diameters according to the second embodiment is that the wafer holder 100 on which the wafer 14 is mounted is shifted (eccentrically) by a distance L toward the side portion 16b of the wafer cassette 16. . That is, the center position of wafer 14 is located on the cover 16a side of wafer cassette 16 compared to the center position of an 8-inch wafer assuming that an 8-inch (first size) wafer is supported in first support groove 16e. Along with this, the second pressing unit 410 is omitted fro...

no. 3 approach

[0163] Next, a third embodiment of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the part which has the same function as each above-mentioned embodiment, and the detailed description is abbreviate|omitted.

[0164] Figure 15 shows the structure of the attachment for substrates with different diameters according to the third embodiment, and Figure 10 corresponding figure, Figure 16 is enlarged Figure 15 An enlarged cross-sectional view of part B of the dotted circle, Figure 17 (a) and (b) are instructions Figure 15 An explanatory diagram of the operation device of the attachment for substrates with different diameters.

[0165] Such as Figure 15 As shown, the attachment 600 for substrates with different diameters according to the third embodiment has a plate-shaped member 601 supported in each of the first support grooves 16 e provided in the wafer cassette 16 . Each pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com