Smectic phase liquid crystal dimming sheet and manufacturing method thereof

A liquid crystal dimming film and smectic phase technology, applied in optics, nonlinear optics, instruments, etc., to achieve high practicability, avoid personal injury, and stabilize astigmatism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

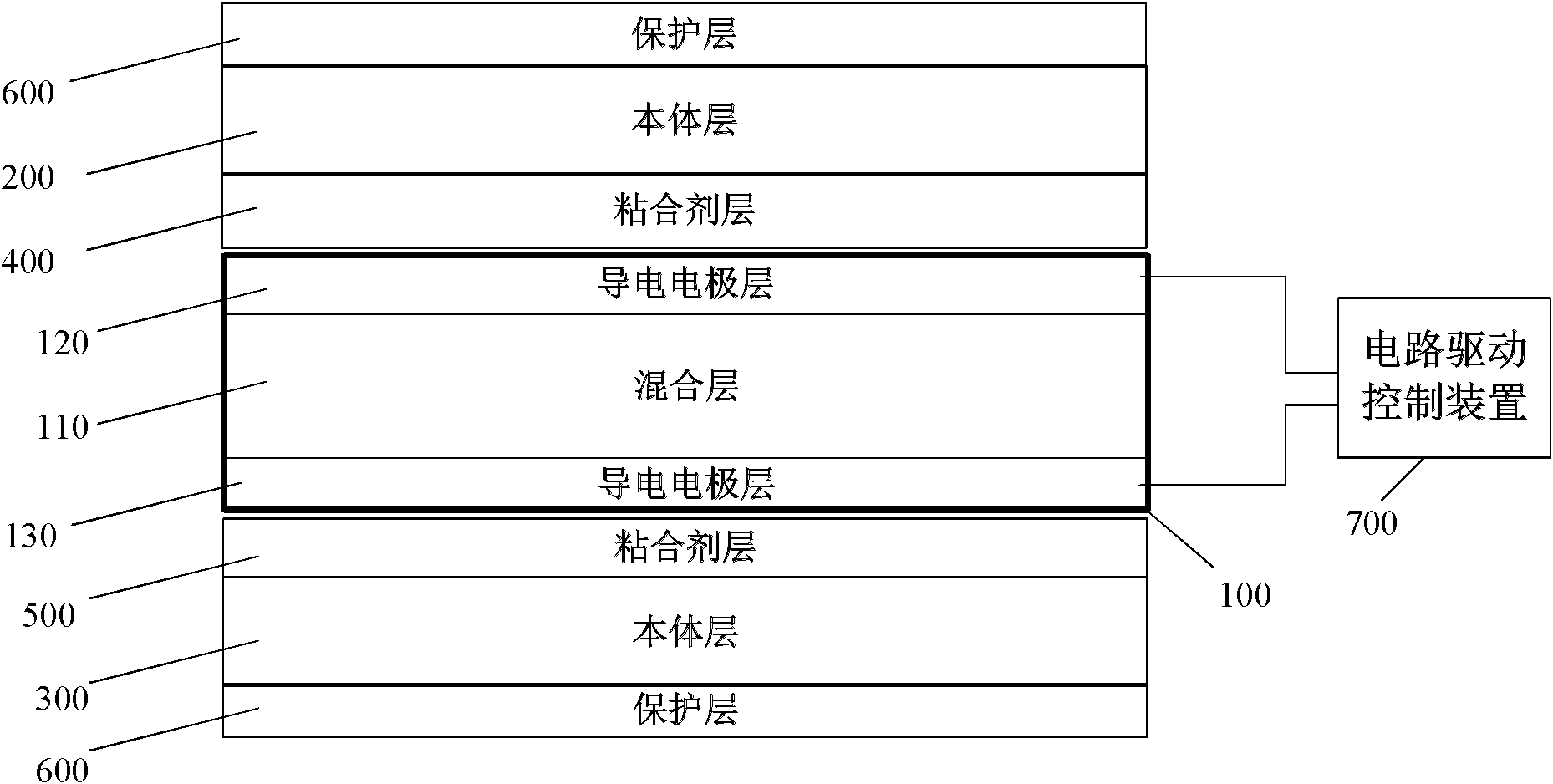

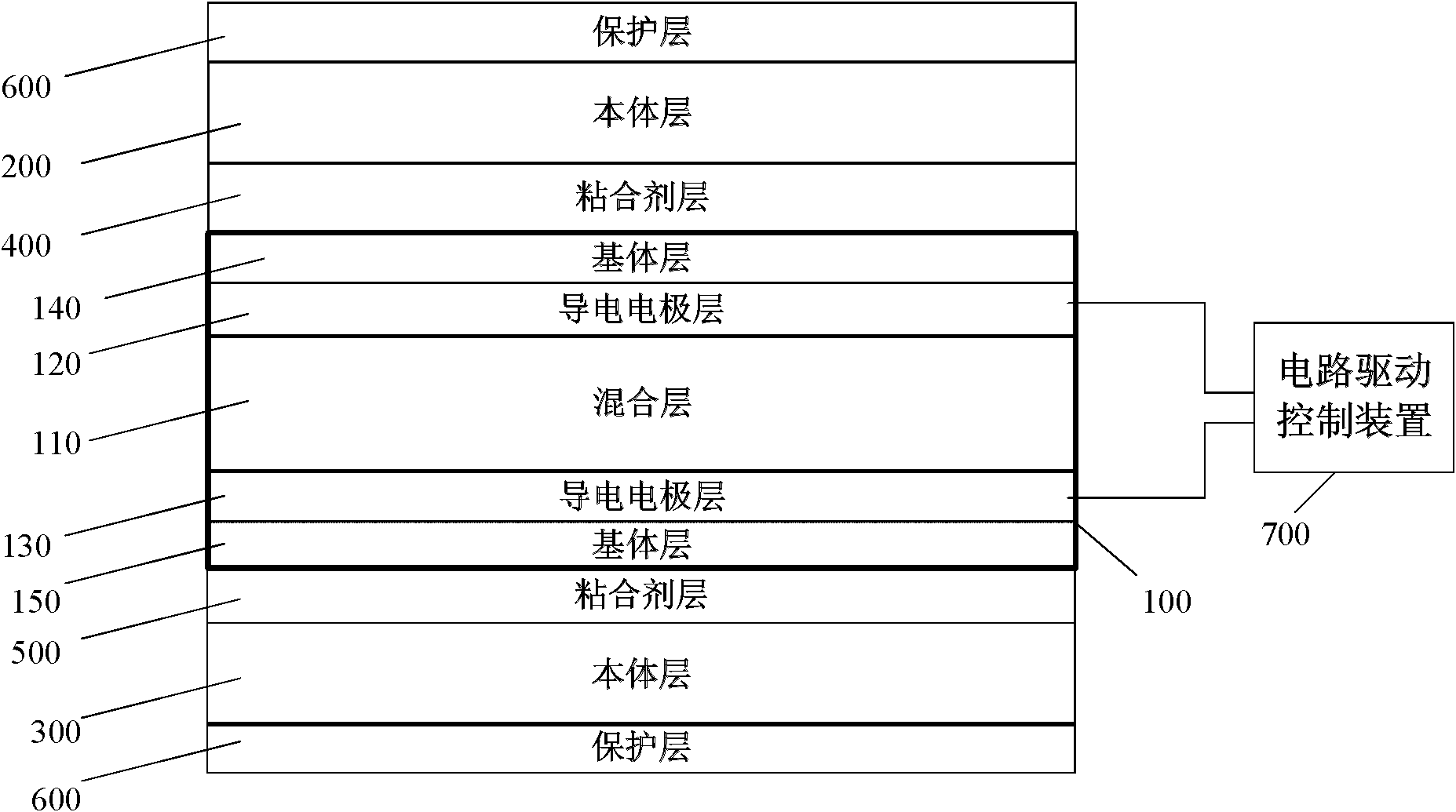

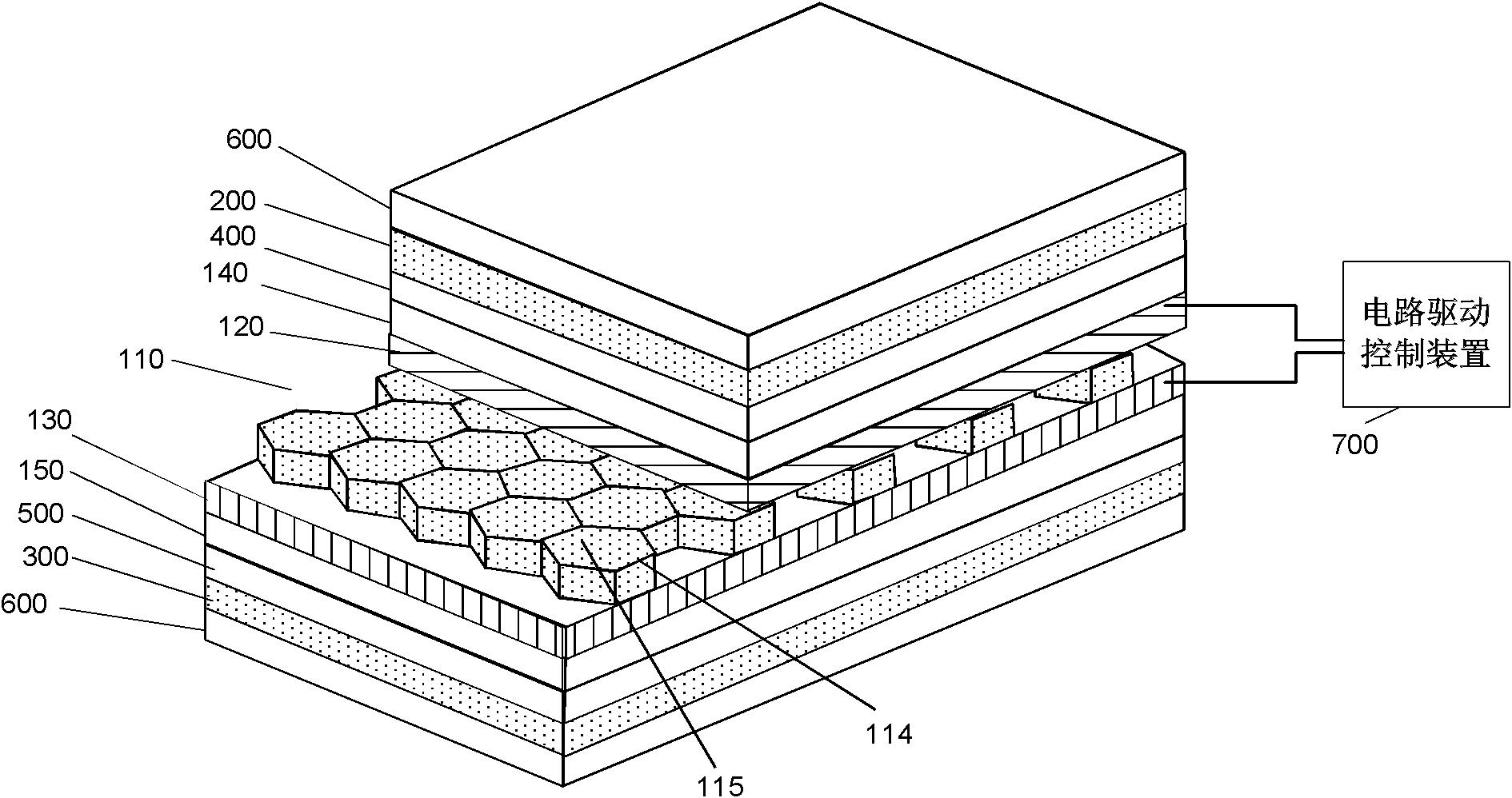

[0030] Such as figure 1 As shown, the smectic liquid crystal dimming film of the present invention includes two body layers 200, 300, and a smectic liquid crystal dimming film layer 100 is arranged between the two body layers 200, 300; the smectic liquid crystal dimming film The layer 100 includes two conductive electrode layers 120, 130, the two conductive electrode layers 120, 130 are connected to the external circuit drive control device 700, and a mixed layer 110 is arranged between the two conductive electrode layers 120, 130, and the mixed layer 110 includes encapsulated in the polymer structure (composed of polymer molecules at the microscopic level, see below), composed of smectic liquid crystals (smectic phase liquid crystal molecules at the microscopic level, see below), conductive objects (conductive objects at the microscopic level) Molecules, see below) and a mixture of spacers, two conductive electrode layers 120, 130 and the mixed layer 110 form a capacitive str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com