Anti-corrosive anti-scaling high-efficiency heat exchanger

A heat exchanger and anti-scaling technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., to achieve the effect of convenient maintenance, not easy to damage, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the present invention in detail with reference to the accompanying drawings, and the purpose and effects of the present invention will become more apparent.

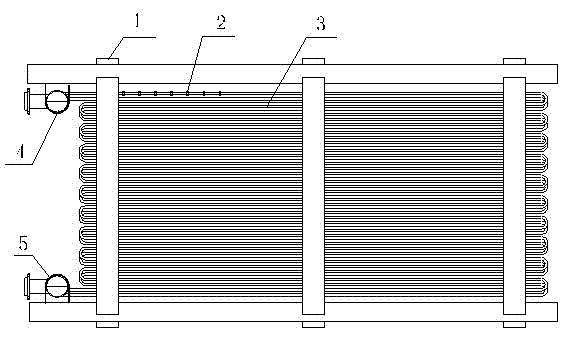

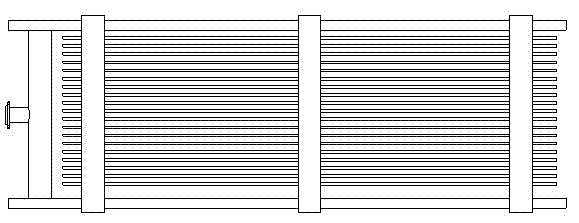

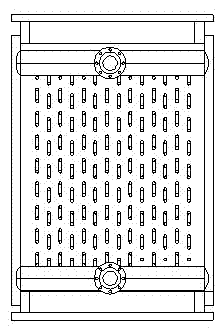

[0023] The anti-corrosion and anti-scaling high-efficiency heat exchanger of the present invention is mainly composed of a bracket 1, a descaling ring 2, a heat exchange coil 3, a heat exchanger inlet header 4, and a heat exchanger outlet header 5, etc. Component composition, figure 1 , figure 2 , image 3 They are the front view, top view and left view of the heat exchanger.

[0024] Such as Figure 4 As shown, the heat exchange coil 3 of the heat exchanger is made of non-metallic materials, which include but are not limited to polymer composite materials and modified thermally conductive composite materials. The heat exchange coil 3 is composed of a plurality of heat exchange coil units superimposed and arranged side by side. Each heat exchange coil unit is made by positioning strips 6 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com