Novel automatically-controlled wood drying kiln

A wood drying kiln, a new type of technology, applied in the direction of drying solid materials, drying chamber/container, drying gas layout, etc., can solve the problems of low detection accuracy, small equipment investment, dry wood cracking, etc. The effect of high efficiency and improved economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

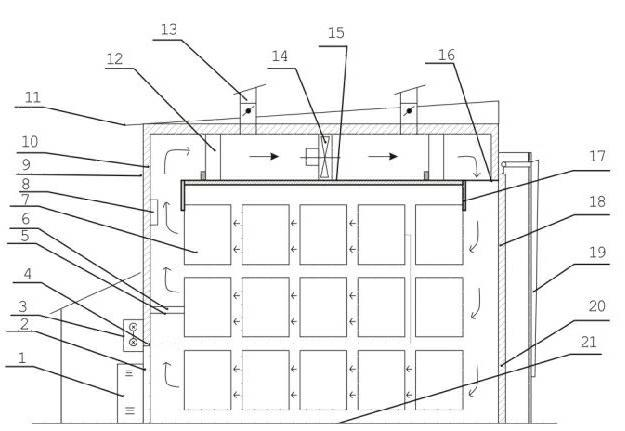

[0031] (1) If the drying kiln is built on the concrete plane, the front gate 18, the walls on the left and right sides, the back wall and the top layer of the kiln use "concave" type groove type hard aluminum alloy as the wall frame material. Aluminum welding, stainless steel bolts, etc. assembled. Glass rock wool is installed in the middle of the wall for thermal insulation. On both sides of the wall frame and thermal insulation rock wool, corrosion-resistant aluminum plates are clamped to make a flat surface of the kiln body, forming the plane of the inner and outer kiln body.

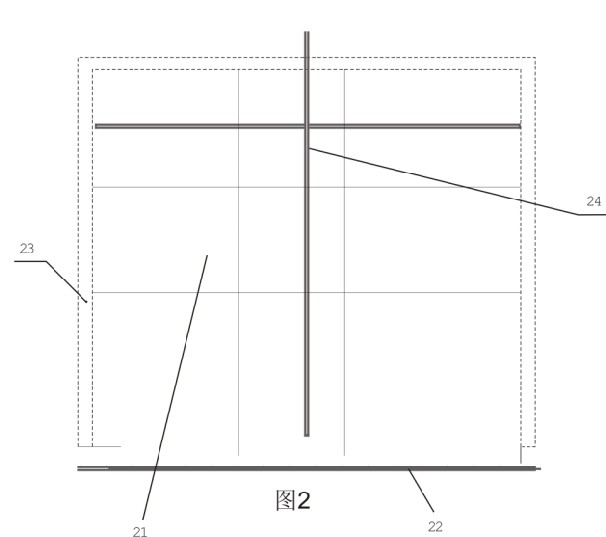

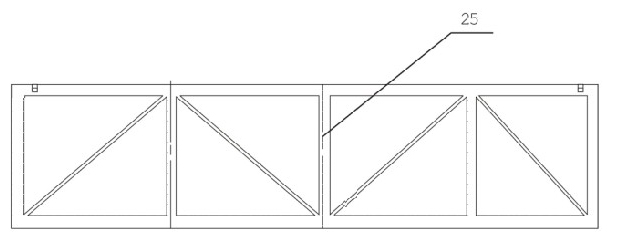

[0032] (2) The total width of the kiln of the drying kiln is 8 meters, the total depth is 7 meters, and the actual height of the kiln is 4.5 meters. Connection, the ceiling bracket 16 is connected with the ceiling baffle 15, and the top circulation channel in the kiln is formed with the ceiling baffle 15 and the interlayer space with a height of 1 meter in the kiln roof. The fan bracket 26 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com