Production line for manufacturing automobile safety part by hot-pressing and molding high-intensity steel plate

A technology of thermoforming and automobile safety, which is applied in the field of machinery, can solve the problems of high manufacturing cost, poor safety, and heavy weight, and achieve the effects of reducing production cost, simplifying the pressing process, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

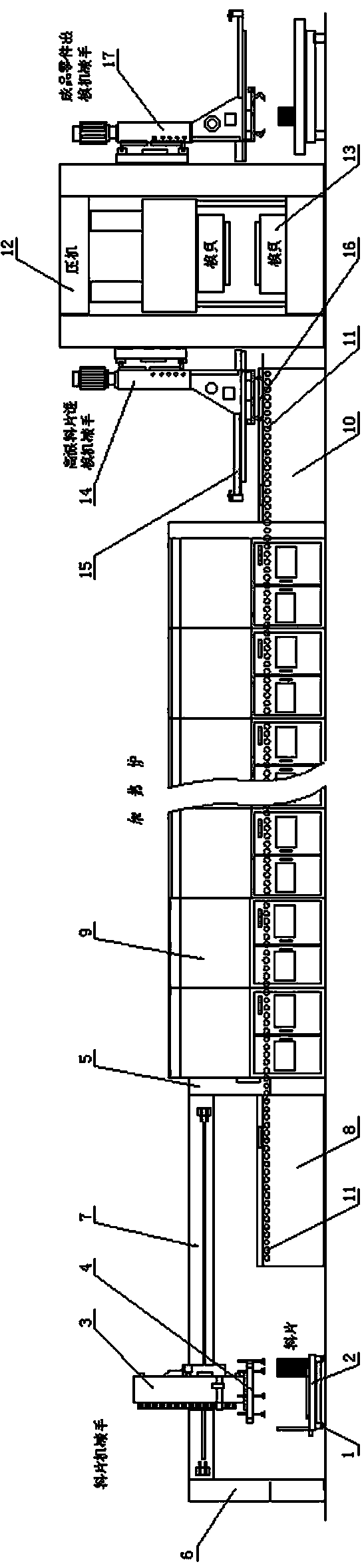

[0010] refer to figure 1 , with material pallet truck, unstacking manipulator, tunnel type heating furnace, high-temperature sheet feeding manipulator, press, mold, and finished product ejecting manipulator to form a production line for manufacturing automobile safety parts by hot pressing of plates. Wherein the material pallet car is made up of rail wheel 1 and flat car body 2, enters and exits the head end of production line through rail. The unstacking manipulator includes a body 3, a vertical linear guide shaft in the body, a gear meshed with a rack on the guide shaft, a gear drive motor and a reduction mechanism, and a suction cup type end picker 4 at the lower end of the body. The unstacking manipulator is supported between the material stacker and the heating furnace by the beam 7 on the door frame 5 across the heating furnace feeding platform 8 and the outer support 6 of the material stacker track, and the crossbeam 7 doubles as the transverse guide shaft of the manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com