Metal plate arch groove forming device

A forming device and a metal plate technology, applied in the field of metal plate forming devices, can solve the problems of complex structure of metal plate arch groove forming tooling, and achieve the effects of simple structure, good forming effect and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

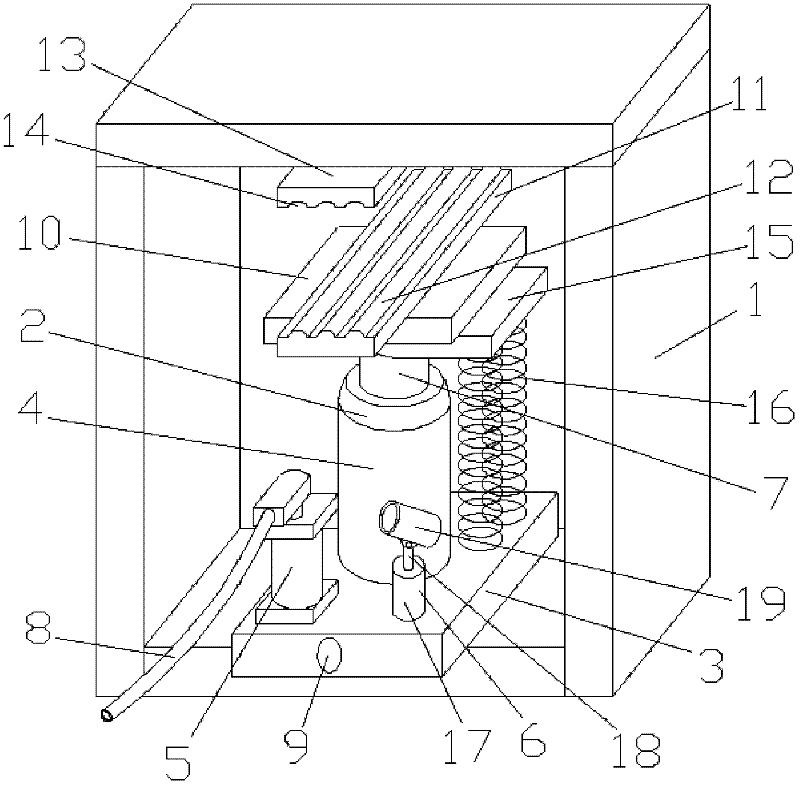

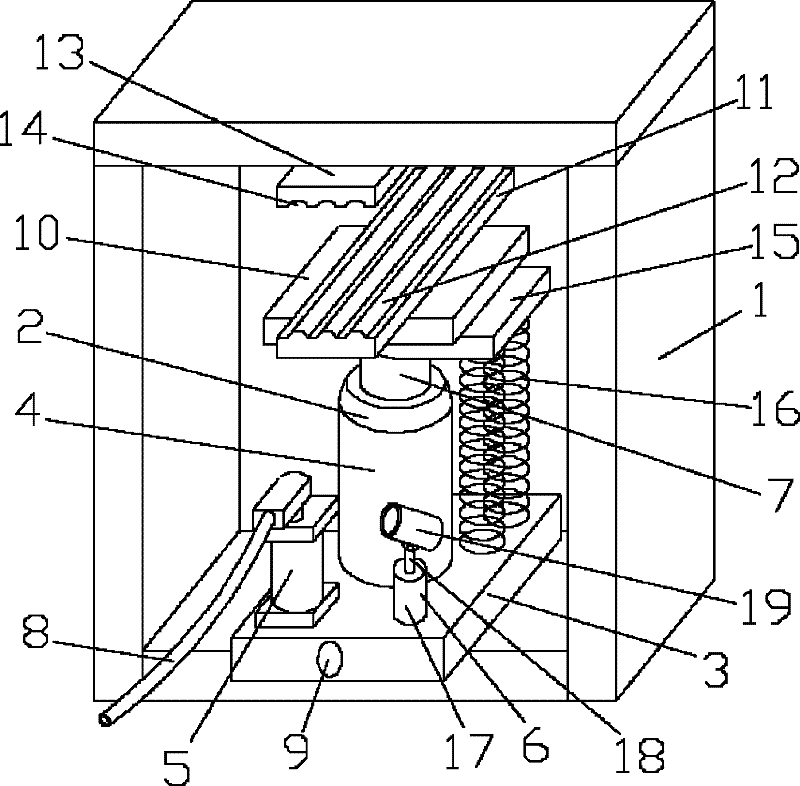

[0010] Such as figure 1 shown. The metal plate arch groove forming device includes a vertically arranged frame body 1, an air cap 2 is installed on the bottom frame of the frame body 1, and the gas cap 2 is composed of an air seat 3, a top cylinder 4 installed on the air seat 3, and an air pump 5. The blockage 6 is composed of the top column 7 which is vertically slidably installed in the top cylinder 4. The air seat 3 is provided with an air inlet and outlet passage which communicates with the inner cavity of the top cylinder 4. The air inlet of the air pump 5 is connected through the air inlet pipe 8. External air source, the air outlet of the air pump 5 is installed on the air seat 3 to communicate with the air intake passage, the air outlet 9 of the air outlet passage in the air seat 3 is opened on the side wall of the air seat 3, and the plug 6 is moved from the air seat 3 to block in In the air outlet channel, the top of the top column 7 protrudes from the top of the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com