Dynamic load simulation device for high-speed railway

A dynamic load, high-speed railway technology, applied in the direction of measuring devices, using stable tension/pressure test material strength, instruments, etc., can solve the problem of not accurately reflecting the main dynamic response characteristics of the railway prototype roadbed, and cannot reflect the dynamics of the high-speed railway roadbed Response characteristics, unable to reflect the dynamic response characteristics of the subgrade, etc., to achieve the effect of high stiffness, increased stiffness, and saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment.

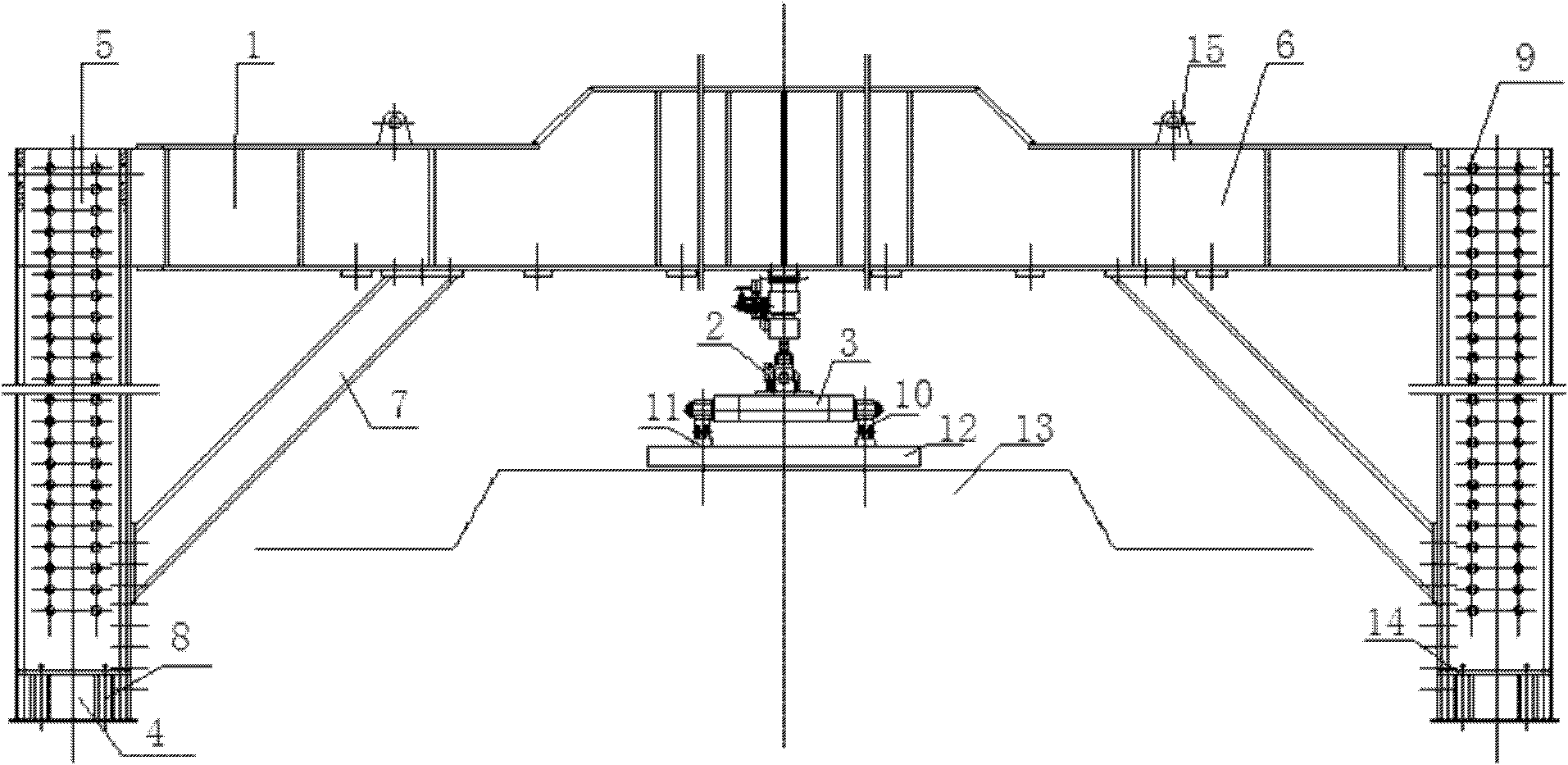

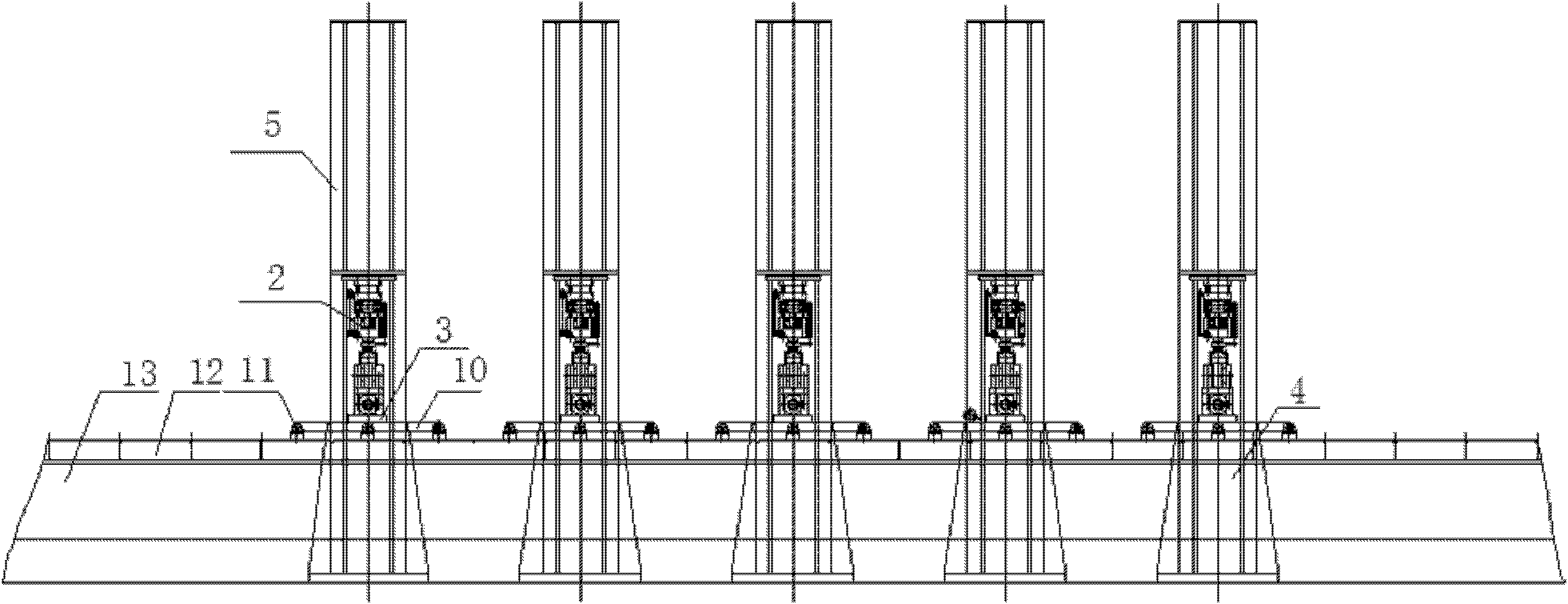

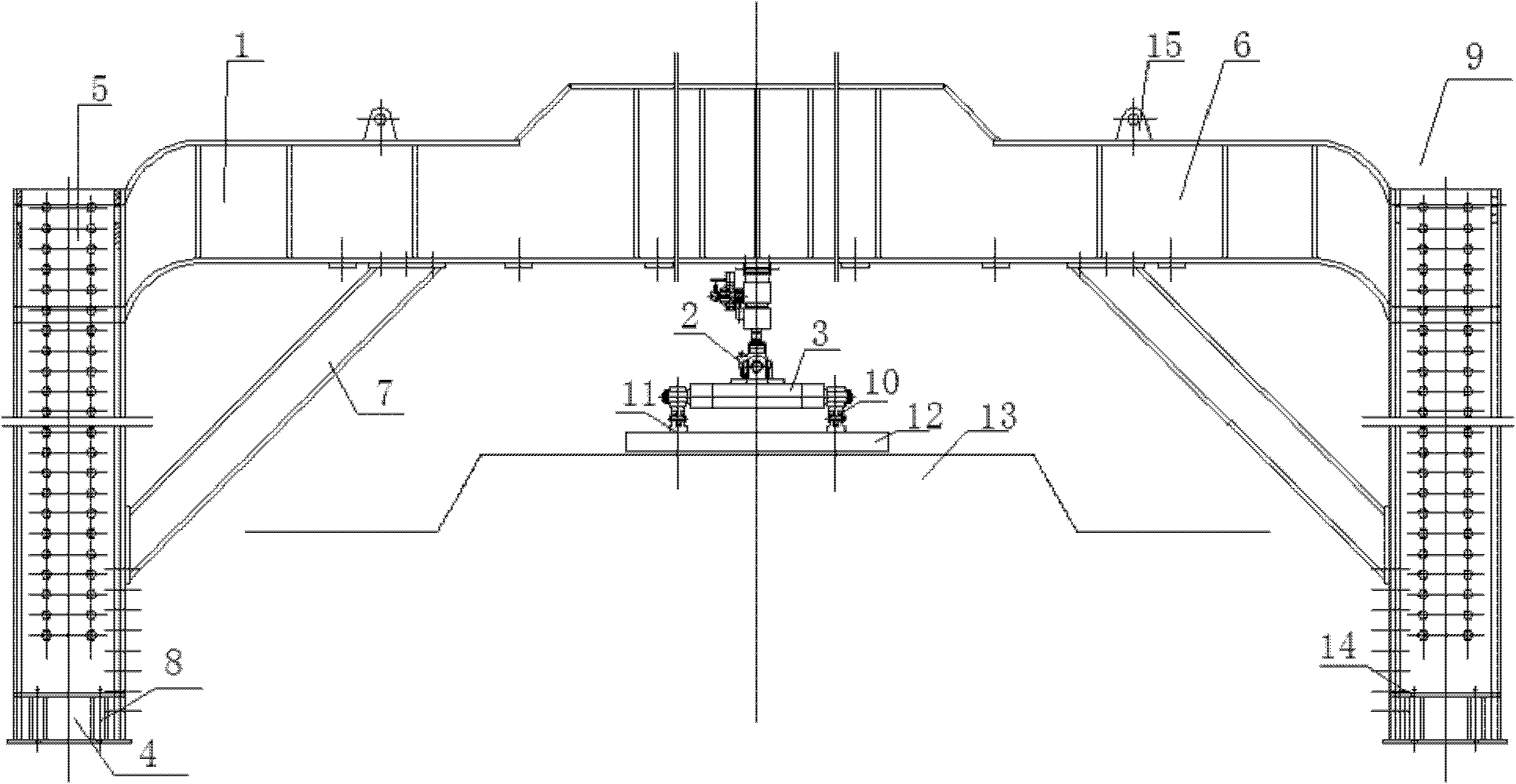

[0036] In an embodiment of the present invention, a high-speed railway dynamic load simulation device includes a reaction frame 1, an actuator 2, and a rigid distribution beam 3. The reaction frame 1 includes a reaction frame foundation 4, a reaction frame column 5, and a reaction frame. The crossbeam 6 and the diagonal brace 7 of the reaction frame are characterized in that: the column 5 of the reaction frame is connected to the foundation 4 of the reaction frame by using the column anchor bolt 8, and the crossbeam 6 of the reaction frame is connected to the reaction frame by using a column hexagonal bolt 9 On the column 5, the two ends of the diagonal brace 7 of the reaction frame are butt-welded with the beam 6 of the reaction frame and the column 5 of the reaction frame respectively by steel plate butt welding, and the upper part of the actuator 2 is connected with the beam 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com