Method for preparing aluminum oxide template by step decompression reaming

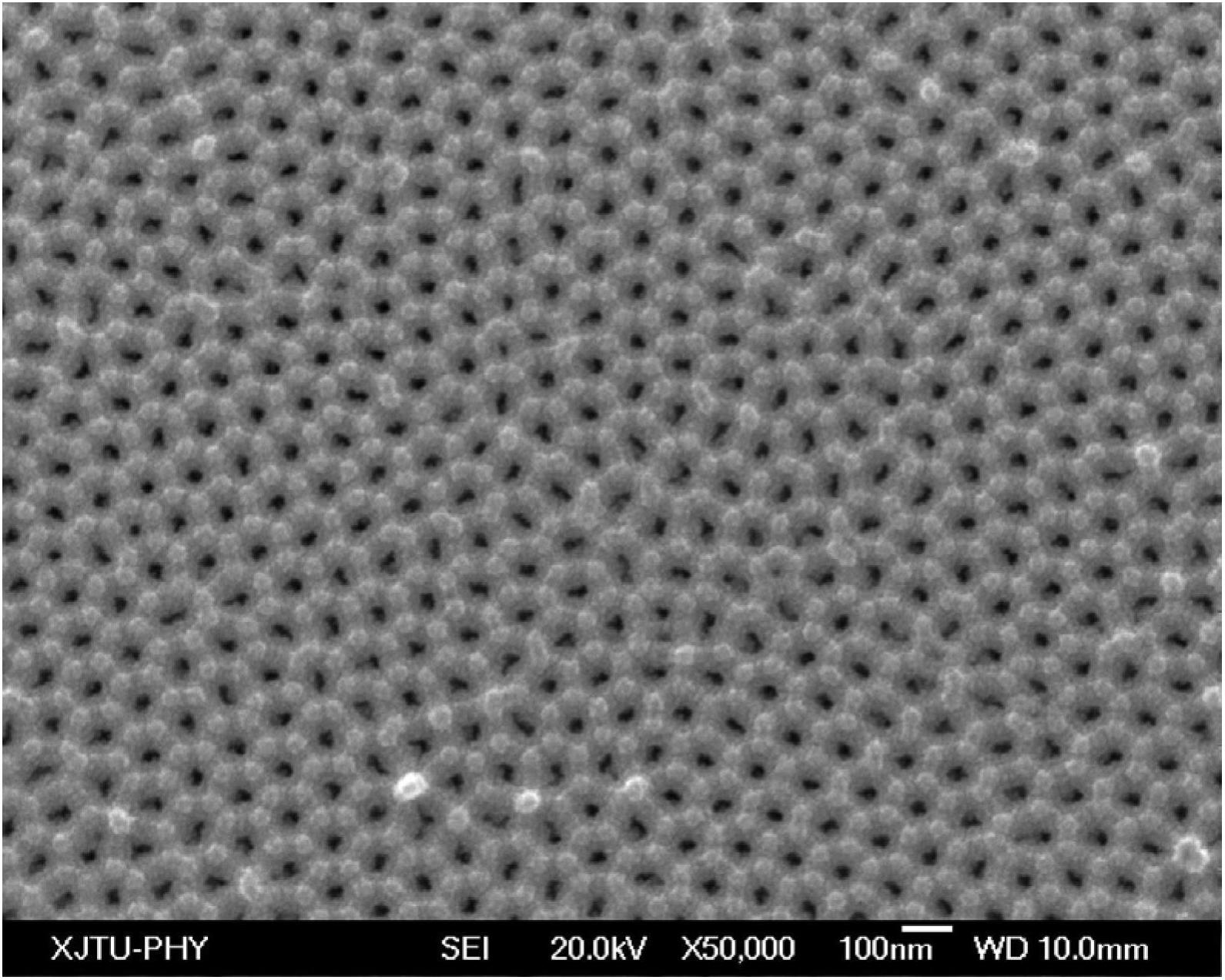

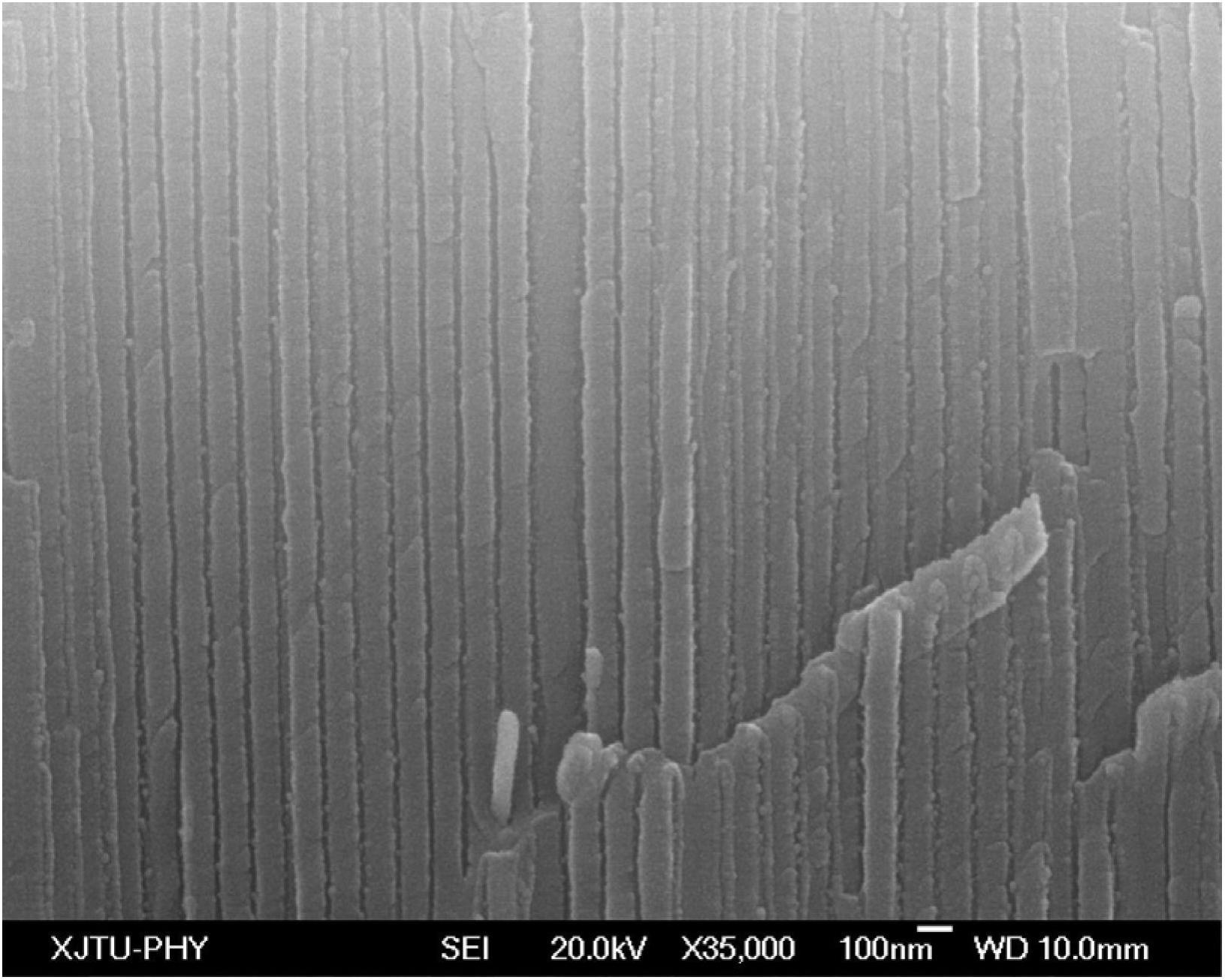

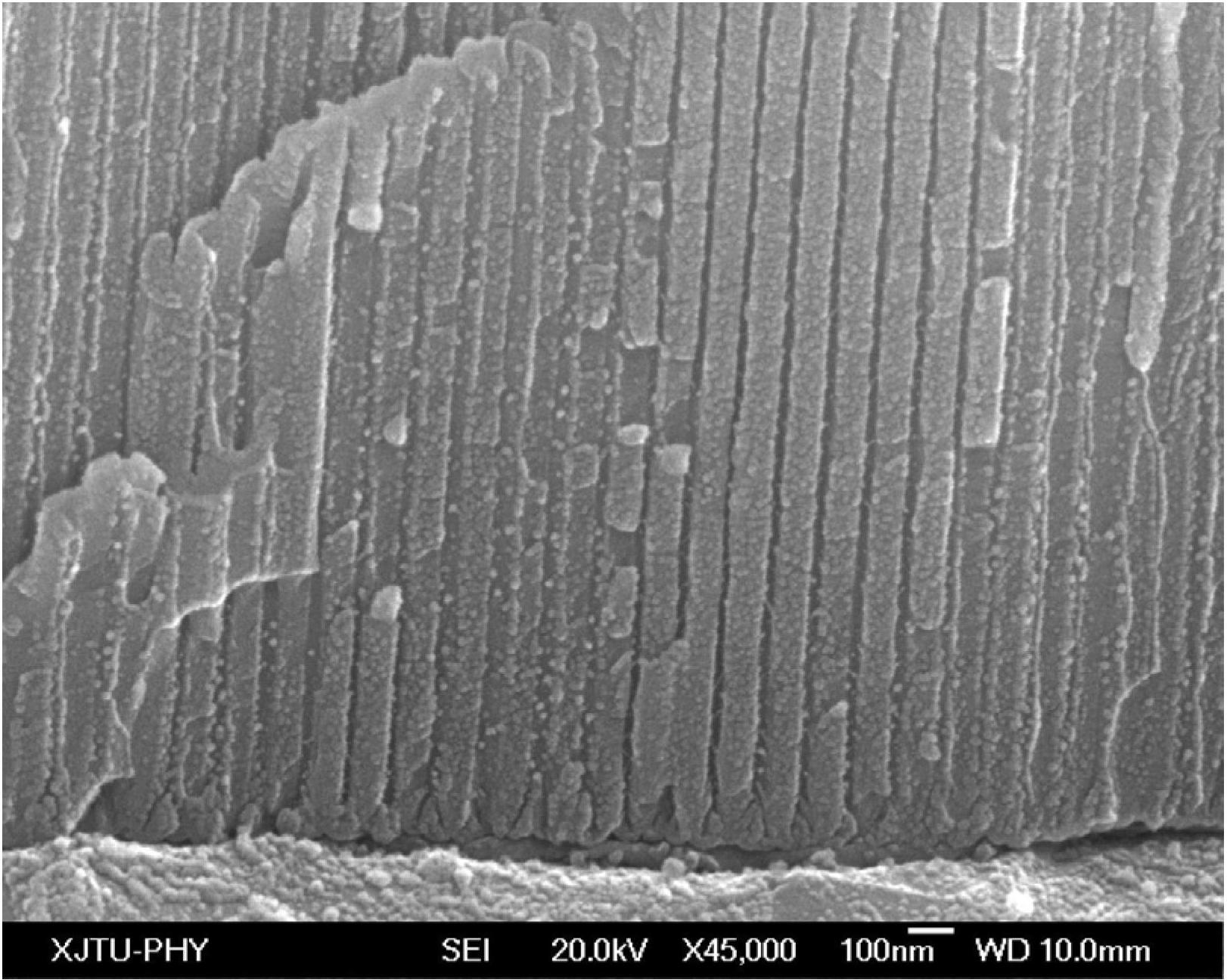

A technology of alumina template and stepped step-down, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., and can solve the problems of unfavorable one-dimensional nanomaterial deposition, low density of nanomaterials, and easily damaged template structure, etc. , to achieve the effect of smooth diffusion process, easy structure completion, and uniform distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 The comparative description of step-down and hole-enlarging treatment on the effect of the prepared template, specifically using the comparison of basic treatment, step-down pressure without hole expansion treatment, and step-down pressure with hole expansion treatment.

[0035] The basic processing described is:

[0036] Anneal high-purity aluminum foil with an area of 3×5cm (purity above 99.99%) in the air at 450°C for 2 hours, put the aluminum foil that has been annealed at high temperature into acetone (99.5%) and ultrasonically clean it for 15 minutes, and then soak it in 20% Sodium hydroxide aqueous solution for 10min, put the aluminum foil into the mixed solution of 60wt% phosphoric acid, 6wt% chromic acid, 15wt% sulfuric acid and 19wt% deionized water for electrochemical polishing. During the polishing process, the anode is aluminum foil, and the cathode is For ring electrodes, the polishing temperature is 70°C, the voltage is 14V, and the polishing ...

Embodiment 2

[0047] The method for preparing an alumina template by step-down depressurization and reaming comprises the following steps:

[0048] 1) Pretreatment of aluminum foil and first anodic oxidation

[0049] Anneal high-purity aluminum foil (purity above 99.99%) and anneal at 450°C in air for 2 hours to remove stress and grain defects in the aluminum foil and improve crystallization performance;

[0050] Ultrasonic cleaning of the annealed aluminum foil to remove surface oil: Put it in 99.5% acetone for ultrasonic cleaning for 15 minutes;

[0051] Then put the aluminum foil in 20% sodium hydroxide solution (mass fraction) for 10 minutes to remove surface alumina, and then electrochemically polish the aluminum foil:

[0052] Put the aluminum foil into a mixed solution with a concentration of 60wt% phosphoric acid, 6wt% chromic acid, 15wt% sulfuric acid and 19wt% deionized water for electrochemical polishing. During the polishing process, the anode is aluminum foil, the cathode is a...

Embodiment 3

[0063] The method for preparing an alumina template by step-down depressurization and reaming comprises the following steps:

[0064] 1) Pretreatment of aluminum foil and first anodic oxidation

[0065] Anneal high-purity aluminum foil (purity above 99.99%) and anneal for 3 hours at 480°C in air to remove stress and grain defects in the aluminum foil and improve crystallization performance;

[0066] The annealed aluminum foil is ultrasonically cleaned to remove surface oil stains: put in 99.5% medium and ultrasonically clean for 10 minutes;

[0067] Then put the aluminum foil into 20% sodium hydroxide solution (mass fraction) for 20min to remove surface alumina, and then electrochemically polish the aluminum foil:

[0068] Put the aluminum foil into a mixed solution of 50wt% phosphoric acid, 10wt% chromic acid, 15wt% sulfuric acid and 25wt% deionized water for electrochemical polishing. During the polishing process, the anode is aluminum foil, the cathode is a ring electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com