Nanometer ferroferric oxide core-carbon meso pore hollow shell complex, as well as preparation method and application thereof

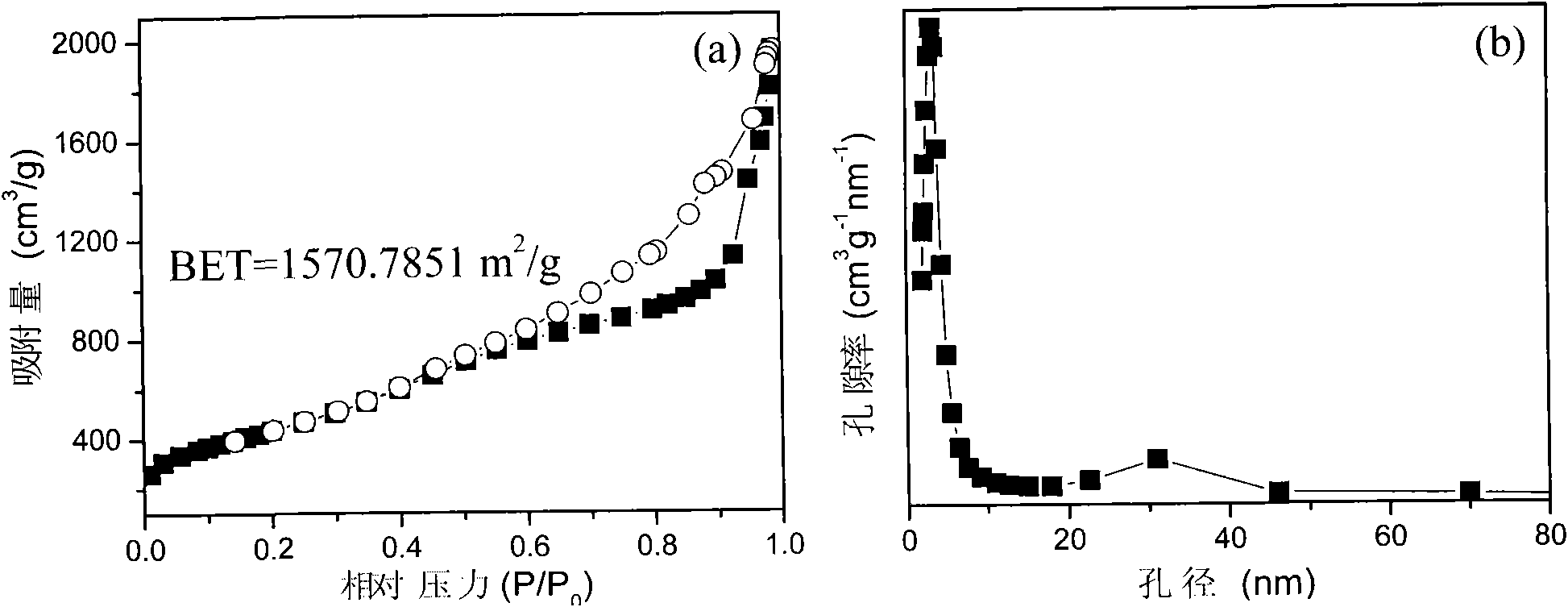

A technology of ferroferric oxide and carbon mesoporous, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of increased discharge of organic sewage, small specific surface area, unfavorable water pollution To solve the problems of adsorption of substances, to achieve strong adsorption capacity, scientific preparation method, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The concrete steps of preparation are:

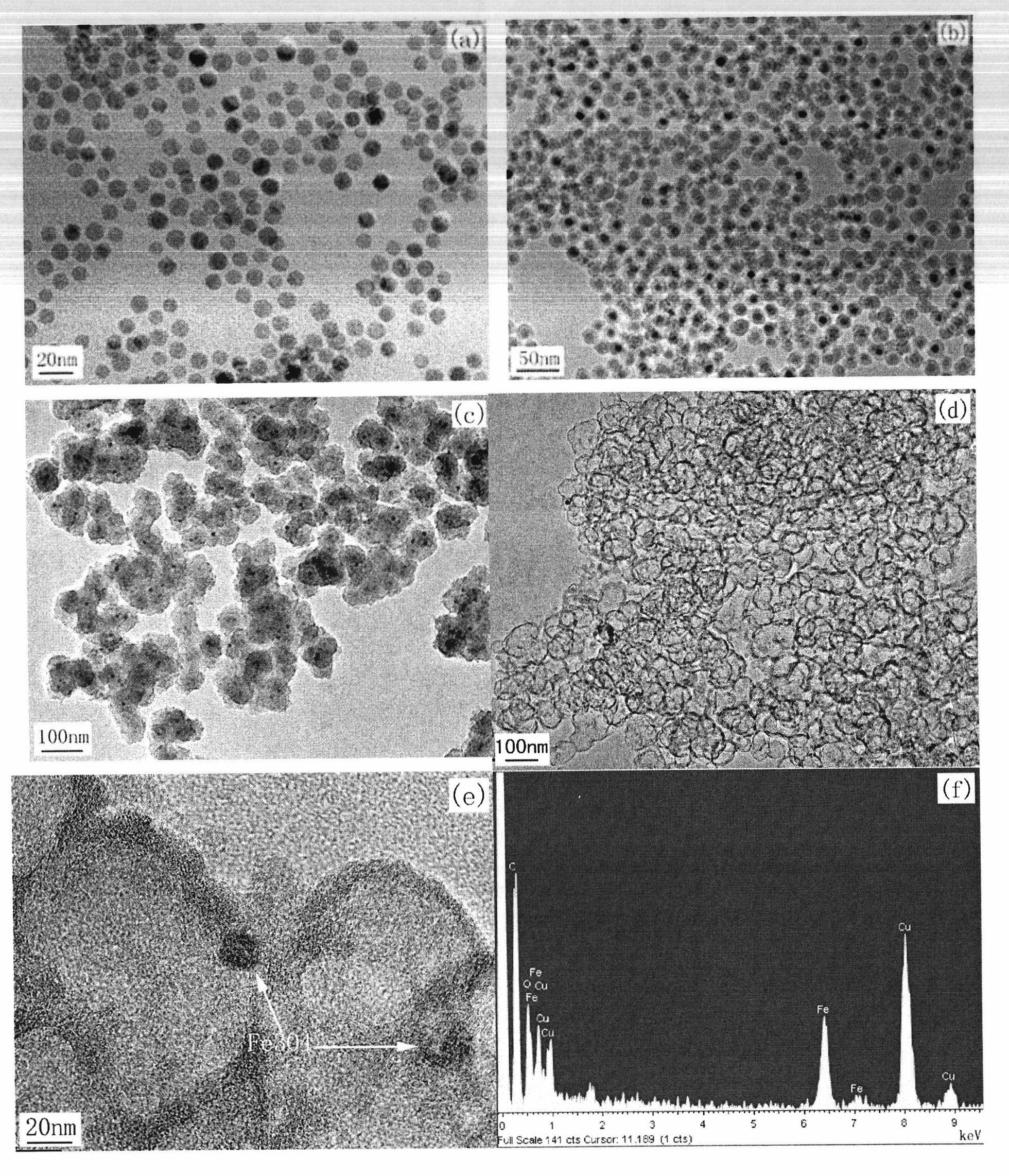

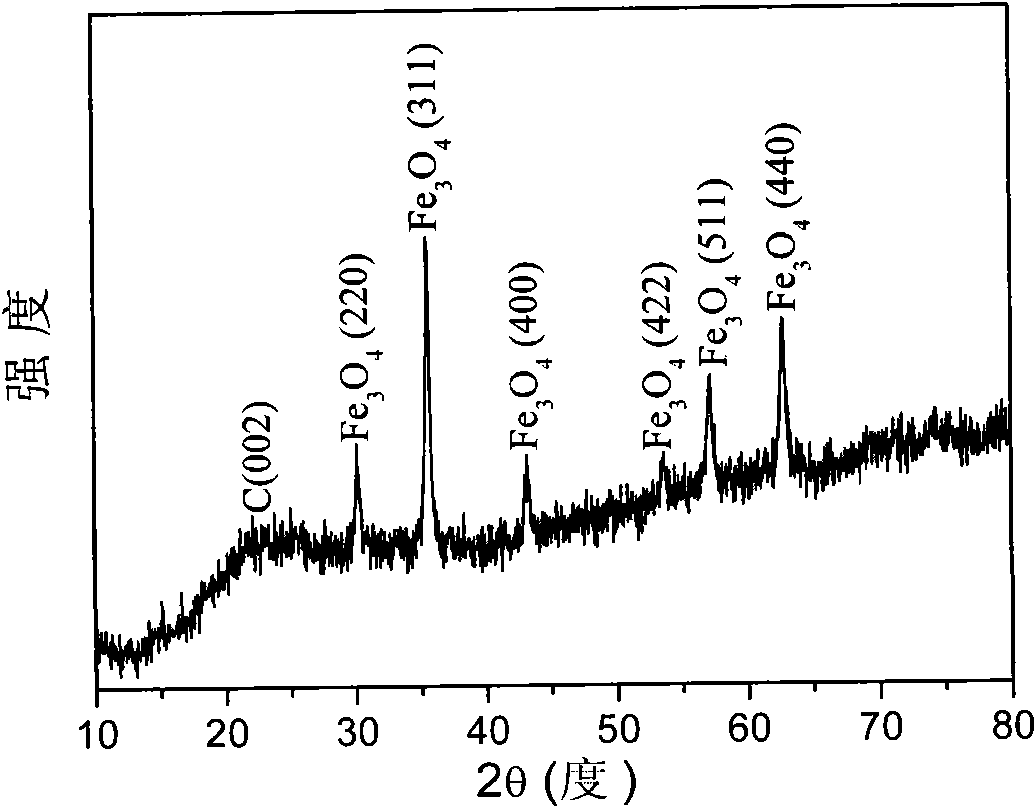

[0033] Step 1, first mix n-hexane, ethanol, deionized water, ferric chloride, oleic acid and sodium hydroxide, and react at 60°C for 4.4h; among them, n-hexane, ethanol, deionized water and oleic acid The volume ratio between them is 7:4:3:0.23, and the molar ratio between ferric chloride, oleic acid and sodium hydroxide is 1:3:3, so as to obtain the iron oleate precursor. Then the ferric oleate precursor, octadecene and oleic acid were mixed according to the molar ratio of 2:1:37, and refluxed at 310°C for 30 minutes, centrifuged and washed to obtain an approximate figure 1 The iron ferric oxide nanocrystal shown in a; wherein, the rotation speed during the centrifugation treatment is 10000r / min, and the washing treatment is to wash once with absolute ethanol.

[0034] Step 2, first disperse nonylphenol polyoxyethylene ether in cyclohexane to obtain nonylphenol polyoxyethylene ether cyclohexane solution; then ultrasonically dis...

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] Step 1, first mix n-hexane, ethanol, deionized water, ferric chloride, oleic acid and sodium hydroxide, and react at 65°C for 4.3h; among them, n-hexane, ethanol, deionized water and oleic acid The volume ratio between them is 7:4:3:0.23, and the molar ratio between ferric chloride, oleic acid and sodium hydroxide is 1:3:3, so as to obtain the iron oleate precursor. Then the ferric oleate precursor, octadecene and oleic acid were mixed according to the molar ratio of 2:1:37, and after reflux at 315°C for 28 minutes, centrifuged and washed to obtain an approximate figure 1 The iron ferric oxide nanocrystal shown in a; wherein, the rotation speed during the centrifugation treatment is 10000r / min, and the washing treatment is washed twice with absolute ethanol.

[0041] Step 2, first disperse nonylphenol polyoxyethylene ether in cyclohexane to obtain nonylphenol polyoxyethylene ether cyclohexane solution; then ultrasonically...

Embodiment 3

[0046] The concrete steps of preparation are:

[0047]Step 1, first mix n-hexane, ethanol, deionized water, ferric chloride, oleic acid and sodium hydroxide, and react at 70°C for 4.2h; among them, n-hexane, ethanol, deionized water and oleic acid The volume ratio between them is 7:4:3:0.23, and the molar ratio between ferric chloride, oleic acid and sodium hydroxide is 1:3:3, so as to obtain the iron oleate precursor. Then the ferric oleate precursor, octadecene and oleic acid were mixed according to the molar ratio of 2:1:37, and refluxed at 320°C for 25 minutes, centrifuged and washed to obtain the following: figure 1 The iron ferric oxide nanocrystal shown in a; wherein, the rotation speed during the centrifugation treatment is 10000r / min, and the washing treatment is to use absolute ethanol to wash 3 times.

[0048] Step 2, first disperse nonylphenol polyoxyethylene ether in cyclohexane to obtain nonylphenol polyoxyethylene ether cyclohexane solution; then ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com