Asymmetric double-crosslinked composite material, as well as preparation method and application of same

A composite material, asymmetric technology, applied in the field of medical materials, can solve the problems of poor mechanical strength and changes of pure sodium hyaluronate, and achieve the effects of good toughness and adhesion performance, good adhesion and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adjust the pH of 10mL hyaluronic acid solution with a concentration of 1% (wt) to 10, and slowly add it dropwise to 10mL chitosan solution with a concentration of 1% (wt) under magnetic stirring at a mass ratio of 1:1 , mix evenly, add 0.015g genipin and stir evenly to obtain A solution.

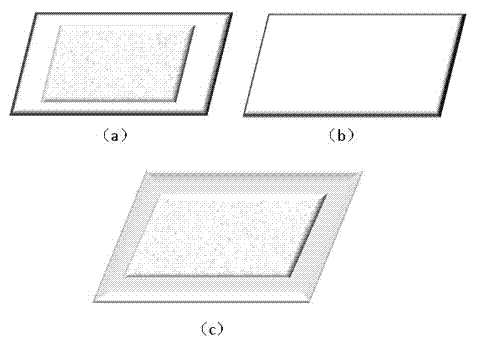

[0032] Pour solution A into the mold and let it stand for 1 hour to form a film at 50°C. After the film was formed, it was neutralized with ammonia gas, and placed in a -80°C refrigerator for precooling for 10 minutes. The solution A was quickly poured onto the pre-cooled composite membrane and frozen in a -80°C refrigerator for 2 hours, then freeze-dried, neutralized with ammonia gas, and sealed for storage.

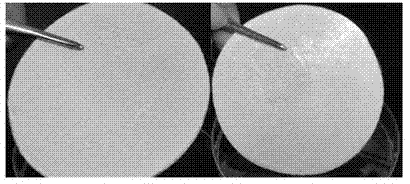

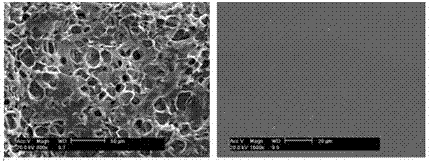

[0033] The asymmetric composite membrane material prepared by this method is light green, with a maximum tensile strength of 0.37 MPa, a tensile modulus of 12.45 MPa, and a maximum tensile rate of 15%. Scanning electron microscope observation as image 3 As shown, the front ...

Embodiment 2

[0035] Adjust the pH of 10mL hyaluronic acid solution with a concentration of 1% (wt) to 10, and slowly add it dropwise to 10mL chitosan solution with a concentration of 1% (wt) under magnetic stirring at a mass ratio of 1:1 , and mix well to obtain A solution.

[0036] Adjust the pH of 10mL of 1% (wt) hyaluronic acid solution to 10, slowly add it dropwise to 10mL of 1% (wt) 2-hydroxypropyl Trimethylammonium chloride chitosan solution, mixed evenly to obtain B solution.

[0037] Pour solution A into the mold and let it stand for 1 hour to form a film at 50°C. After the film was formed, it was neutralized with ammonia gas, and placed in a -80°C refrigerator for precooling for 10 minutes. Pour solution B quickly onto the pre-cooled composite membrane and freeze in a -80°C refrigerator for 2 hours, then lyophilize, neutralize with ammonia gas, and store in a sealed container.

[0038] The asymmetric composite membrane material prepared by this method is white, with a maximum t...

Embodiment 3

[0040] Adjust the pH of 10mL hyaluronic acid solution with a concentration of 1% (wt) to 9, and slowly add it dropwise to 10mL chitosan solution with a concentration of 2% (wt) under magnetic stirring at a mass ratio of 1:2 , and mix well to obtain A solution.

[0041] Adjust the pH of 10 mL of 0.5% (wt) hyaluronic acid solution to 10, and slowly add it dropwise to 10 mL of 0.5% (wt) hydroxymethyl chitosan under magnetic stirring at a mass ratio of 1:1. Sugar solution, mix well to get B solution.

[0042] Pour solution A into the mold and let it stand for 1 hour to form a film at 50°C. After the film was formed, it was neutralized with ammonia gas, and placed in a -80°C refrigerator for precooling for 10 minutes. Pour solution B quickly onto the pre-cooled composite membrane and freeze in a -80°C refrigerator for 2 hours, then lyophilize, neutralize with ammonia gas, and store in a sealed container.

[0043]The asymmetric composite membrane material prepared by this method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com