High-power direct current/square wave changing circuit and control method therefor

A conversion circuit and high-power technology, which is applied in the field of high-power DC/square wave conversion circuit and its control, can solve the problems of the highest frequency and minimum duty ratio limitation, the inability to output asymmetric voltage pulse voltage waveform, etc., and achieve waveform quality High, positive and negative pulse conversion speed is fast, the effect of a large duty cycle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

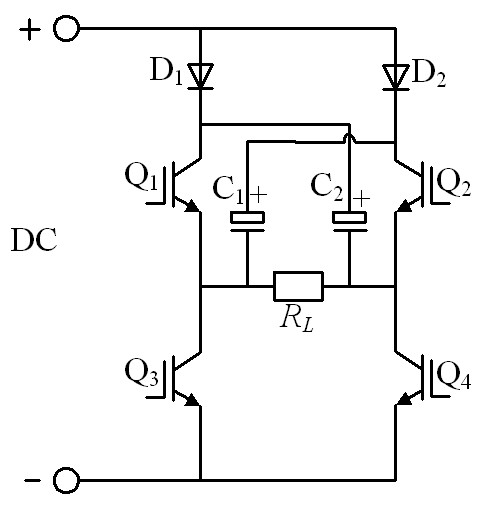

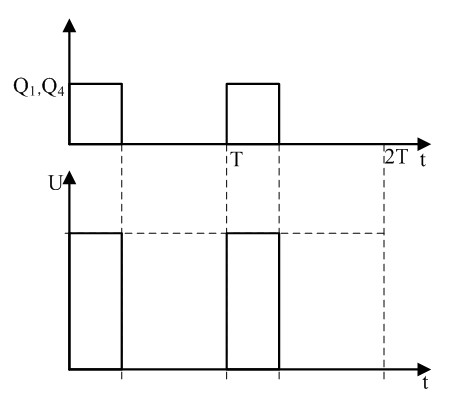

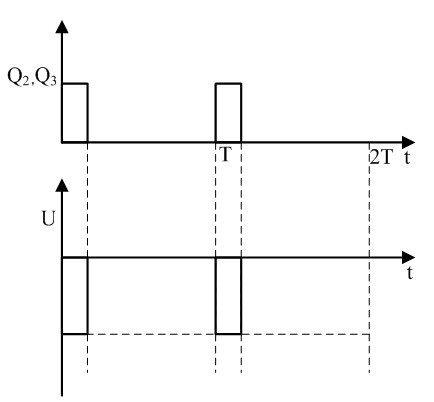

[0024] figure 1 It is an example diagram of a high-power DC / square wave conversion circuit according to an embodiment of the present invention. The high-power DC / square wave conversion circuit includes four switching tubes: the first switching tube Q 1 , the second switching tube Q 2 , the third switching tube Q 3 , the fourth switching tube Q 4 , two fast recovery diode modules: the first fast recovery diode module D 1 , the second fast recovery diode module D 2 , two capacitor modules: the first capacitor module C 1 , the second capacitor module C 2 ; The four switching tubes Q 1 -Q 4 The first switching tube Q in 1 and the third switching tube Q 3 The first side bridge arm of the H-bridge circuit is formed in series, and the connection is led out to be the output end of the first side bridge arm of the H-bridge circuit; the first switch tube Q 1 of the high side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com