Optimum design method of heat sink based on Taguchi method

An optimized design and heat sink technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve the problems of design cost and cycle waste, unable to optimize the heat sink, unable to guarantee the heat sink parameters, etc., to solve the problem of uncertainty , saving design costs and shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

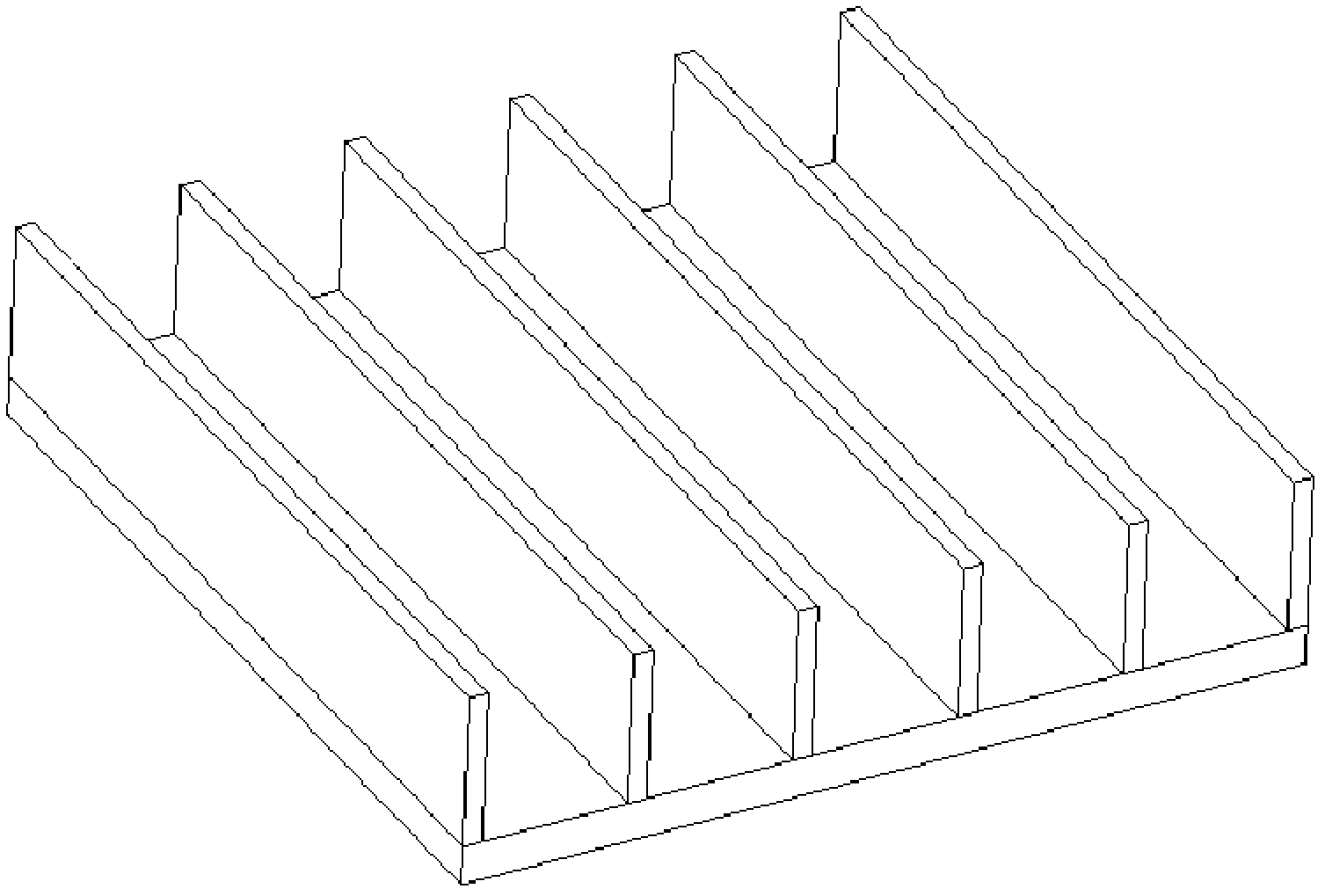

[0059] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and an optimal design case of a heat sink for a high-power device of an electronic device.

[0060] See figure 1 , the present invention is a kind of heat sink optimal design method based on Taguchi method, and the concrete steps of this method are as follows:

[0061] Step 1: Case introduction and parameter selection

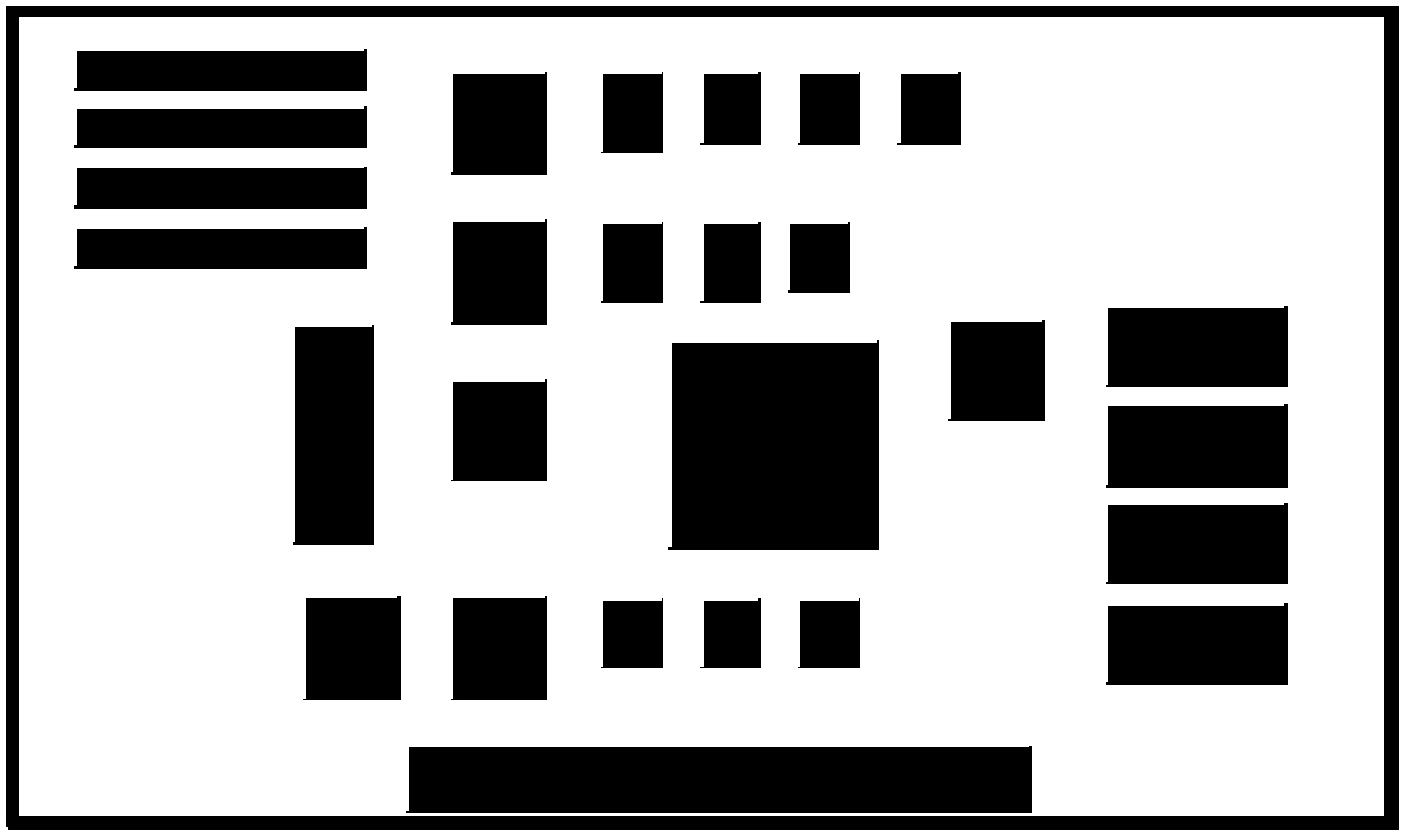

[0062] As a case board such as figure 2 As shown, the size of the circuit board is 180mm×100mm×2mm, including 7 different types of electronic components. The total power consumption of the board is 14.5W.

[0063] Among them, the electronic components in the middle of the circuit board are high-power devices, and their heat dissipation power consumption is 4W, accounting for 27.6% of the total power consumption of the printed circuit board. The external dimensions of the high-power device are 30mm×30mm×2mm, and its packaging form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com