Fatigue property test device of 4.2-300K temperature area

A technology of fatigue performance testing and fatigue testing machine, which is applied in the direction of testing material strength by applying stable bending force and testing material strength by applying stable tension/pressure, which can solve the problems of fatigue performance data measurement and achieve simple structure , accurate temperature control and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

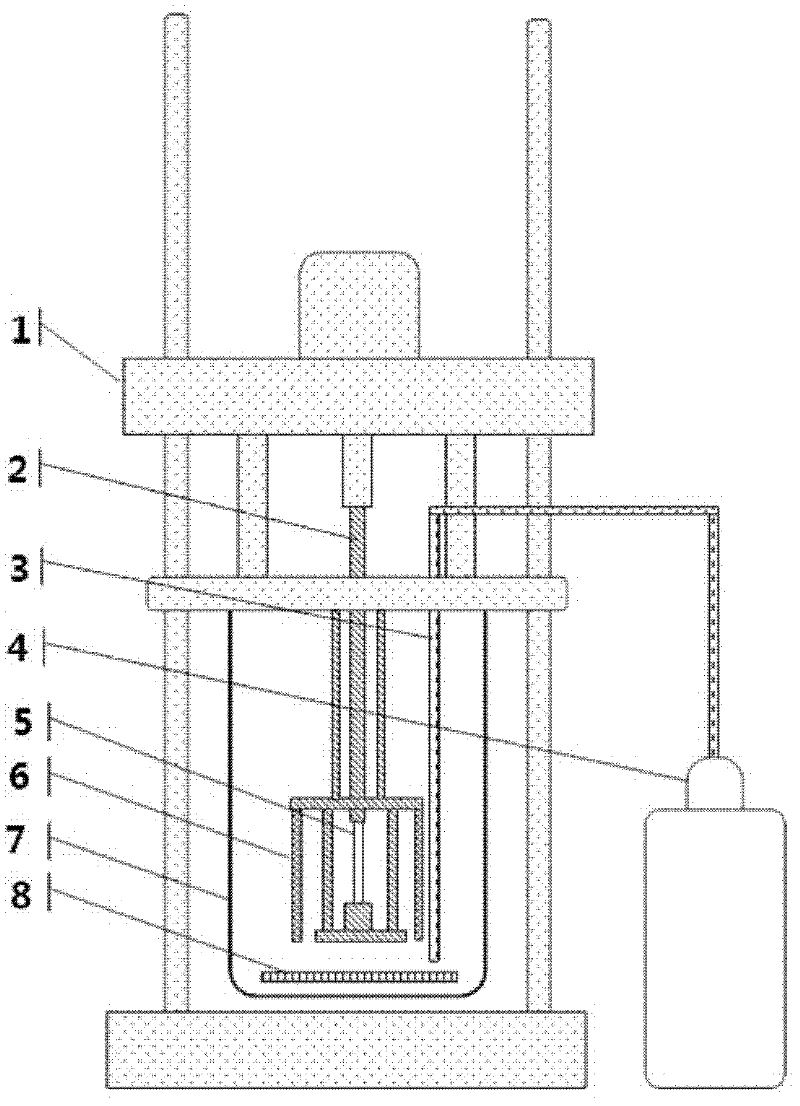

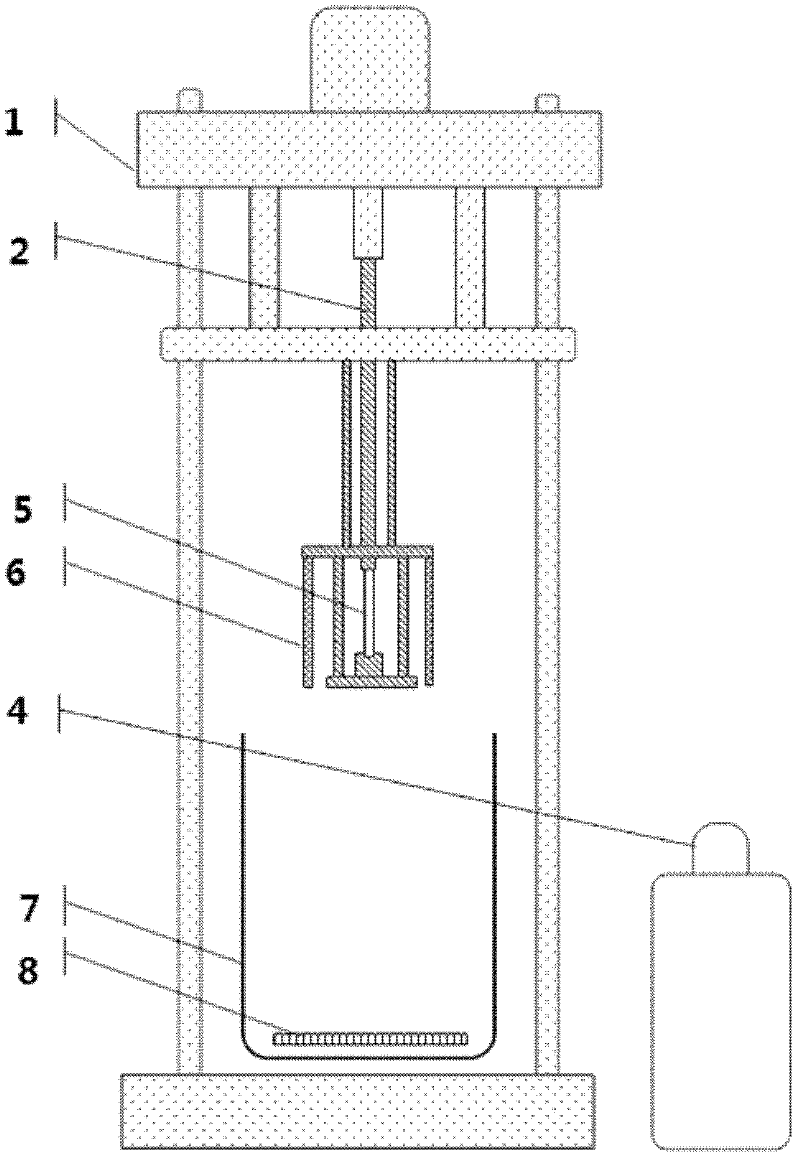

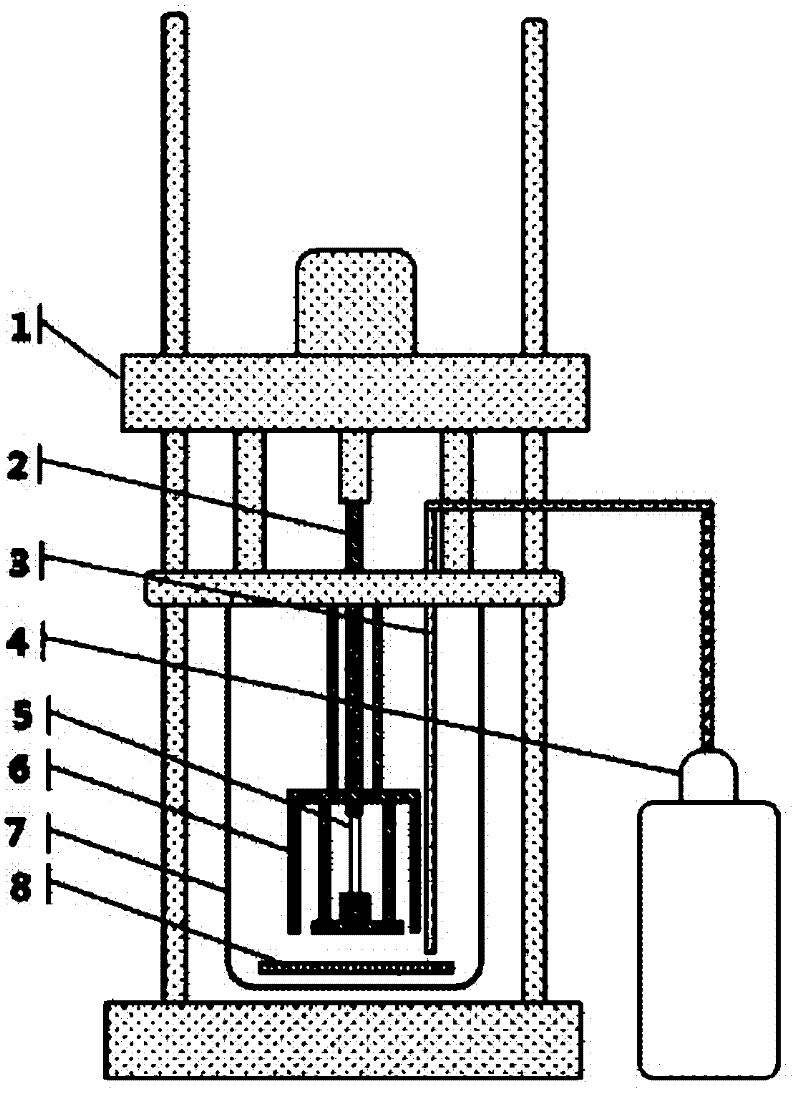

[0027] figure 1 It is a structural schematic diagram of the low temperature fatigue performance measuring device of the present invention. Such as figure 1 As shown, the low-temperature fatigue performance measurement device of the present invention mainly includes: electro-hydraulic servo fatigue testing machine 1, low-temperature mechanical support frame 2, low-temperature liquid infusion tube 3, low-temperature liquid container 4, sample or sample 5 to be tested, and a temperature controller 6. Low temperature vacuum Dewar 7, low temperature liquid evaporator 8, etc. Only a few main components are described in detail below. Systems or elements (such as vacuum systems, valves for controlling liquid flow) that are well known to those skilled in the art will not be further described in the present invention.

[0028] The electro-hydraulic servo fatigue testing machine 1 provides a mechanical power source (ie loading force) for the sample 5, and it also includes a mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com