Bridge type tool for measuring high-precision camera mounting surface

A mounting surface, high-precision technology, applied in artificial horizontal plane and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

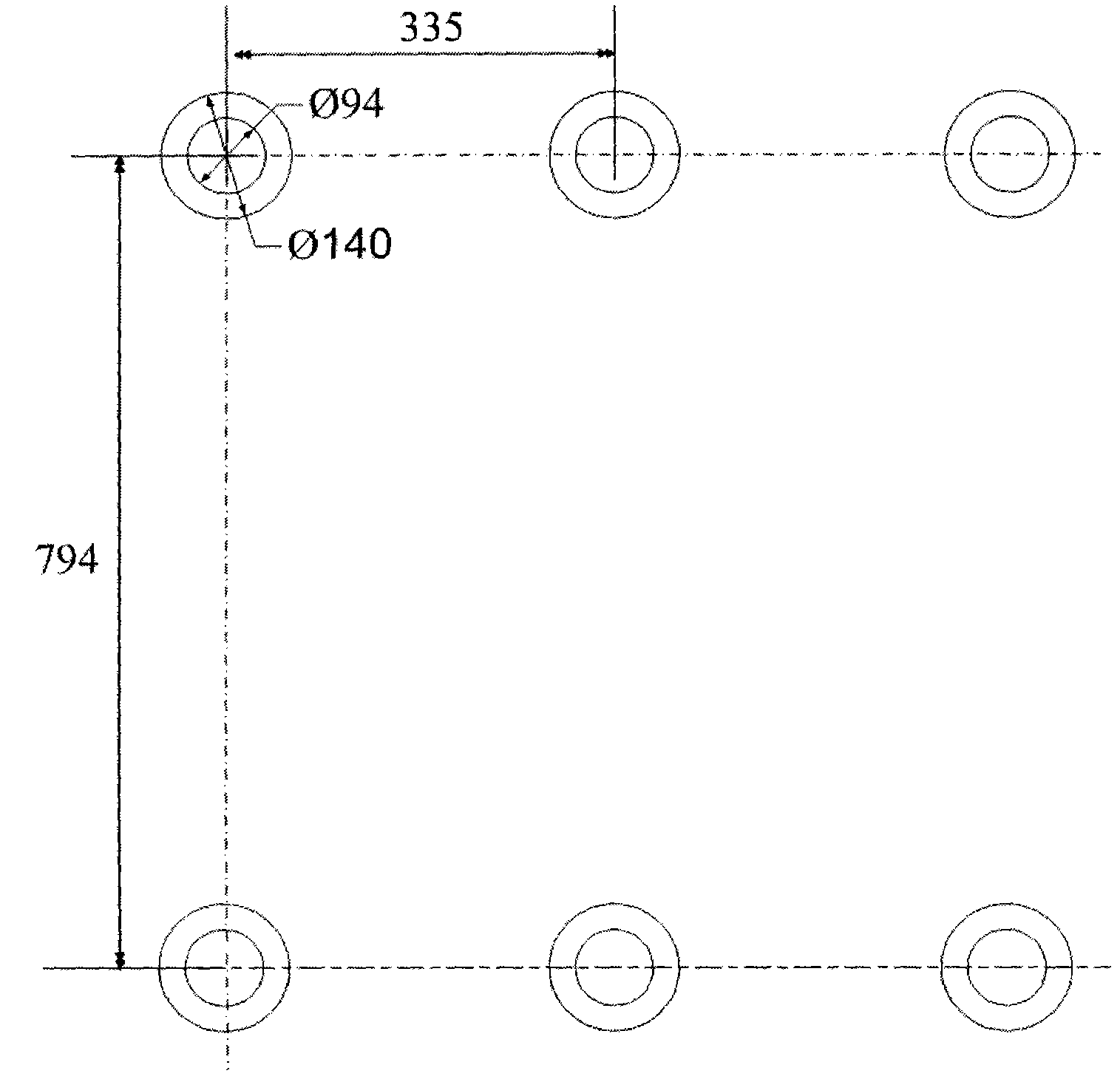

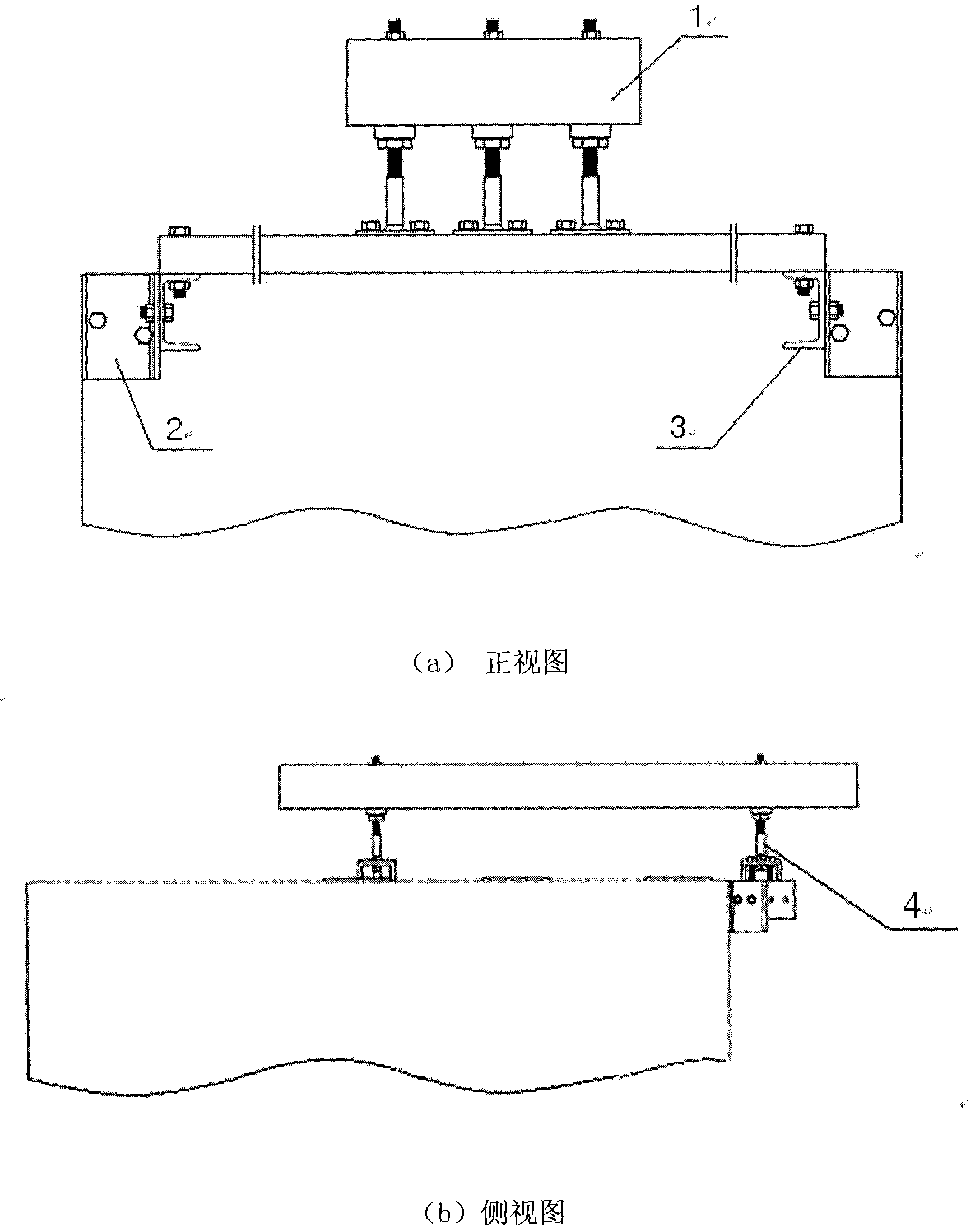

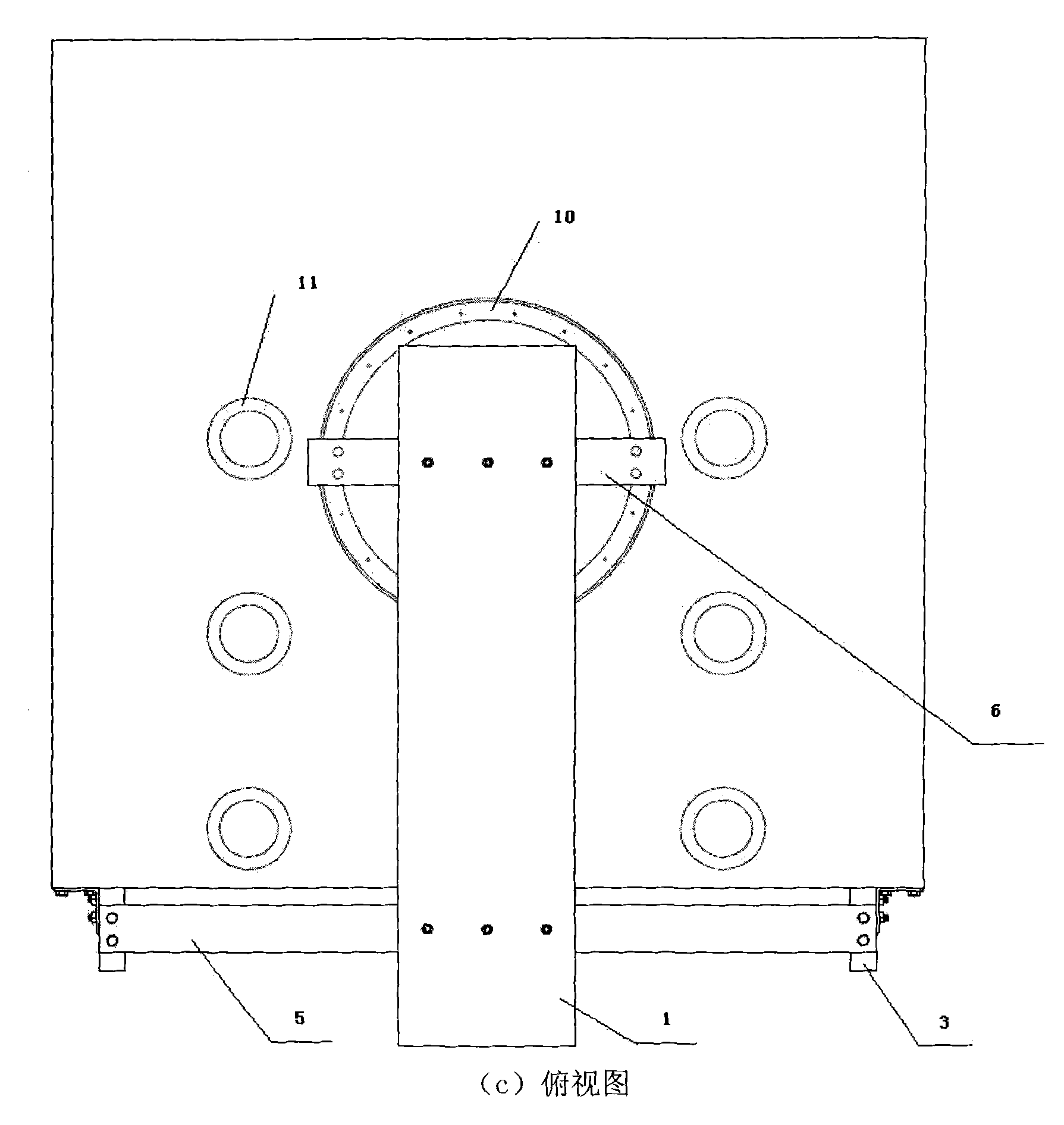

[0019] like figure 2 and image 3 As shown, a bridge-type tooling for measuring the installation surface of a high-precision camera is composed of a parallel gauge 1, an angle piece 2, a channel steel 3, a support and levelness adjustment device 4, a long support beam 5, a short support beam 6, a spacer 7, Support rod 8 and fasteners are formed. Among them, the angle piece 2 is connected with the side plate of the structure to be measured through two sets of fasteners, the channel steel 3 is connected with the angle piece 2 through two sets of fasteners, and the long support beam 5 is connected with two sets of fasteners through four sets of fasteners. The channel steel is connected. The six support and levelness adjusting devices 4 are respectively connected with the long and short support beams by two sets of fasteners. The short support beam 6 is connected to the load-bearing cylinder of the structure to be measured through pads 7 and support rods 8 . The parallel gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com