Lubricating grease filling machine for building machinery

A construction machinery and lubricating grease technology, which is applied in the direction of engine lubrication, lubricating pumps, mechanical equipment, etc., can solve problems such as discontinuous oiling action, manual operation accidents, high risk, etc., to achieve easy and safe lubrication maintenance, stable and reliable work , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

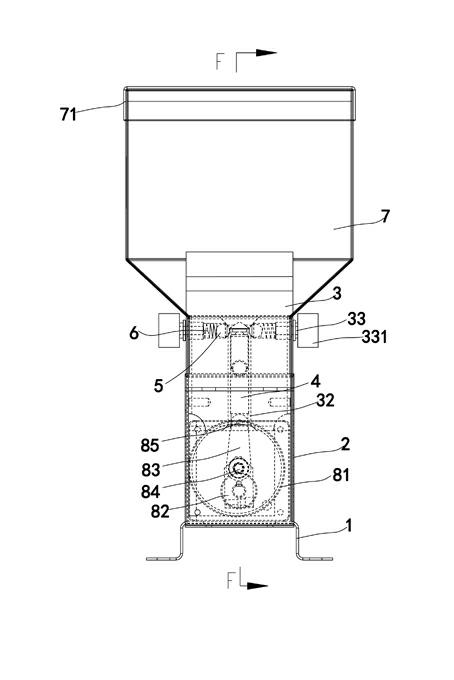

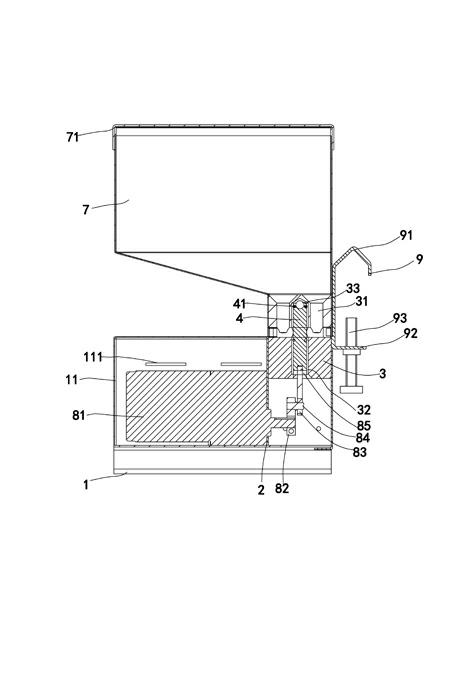

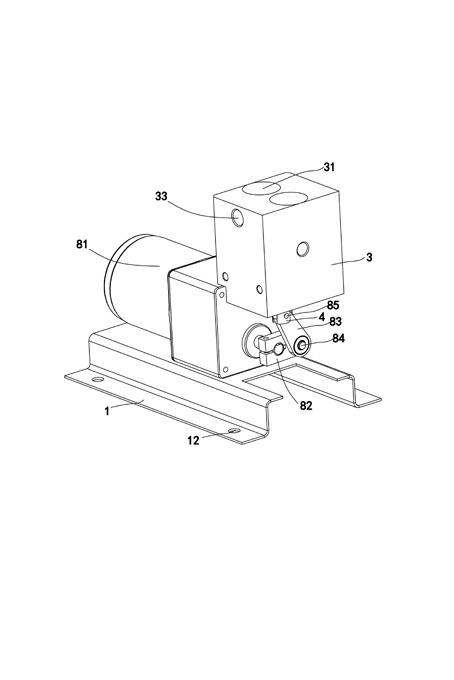

[0023] refer to Figure 1 to Figure 3 , this embodiment discloses a grease filling machine for construction machinery, including a base 1, an oil block bracket 2, an oil block 3, a piston valve core 4, two pressing balls 5, two springs 6 and an oil storage bucket 7 , the oil block bracket 2 is set on the base 1, the oil block 3 is detachably fixed on the top of the oil block support 2 by bolts, and the upper part of the oil block 3 is provided with two oil inlet holes 31 , the lower part is provided with an air pressurization chamber 32, the two oil inlet holes 31 are connected with the air pressurization chamber 32, and the two oil inlet holes 31 on the upper part of the oil block 3 are provided with an air pressurization chamber 32. The two oil outlet holes 33 are connected, and the piston spool 4 is set on the air pressurization chamber 32 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com