One-step production method for cerium poor rare earth fluoride and cerium fluoride

A technology of rare earth chloride and cerium fluoride, which is applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high treatment cost, high cost, and high labor intensity, and achieve equipment efficiency improvement, energy The effect of reducing consumption and reducing fluorine emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

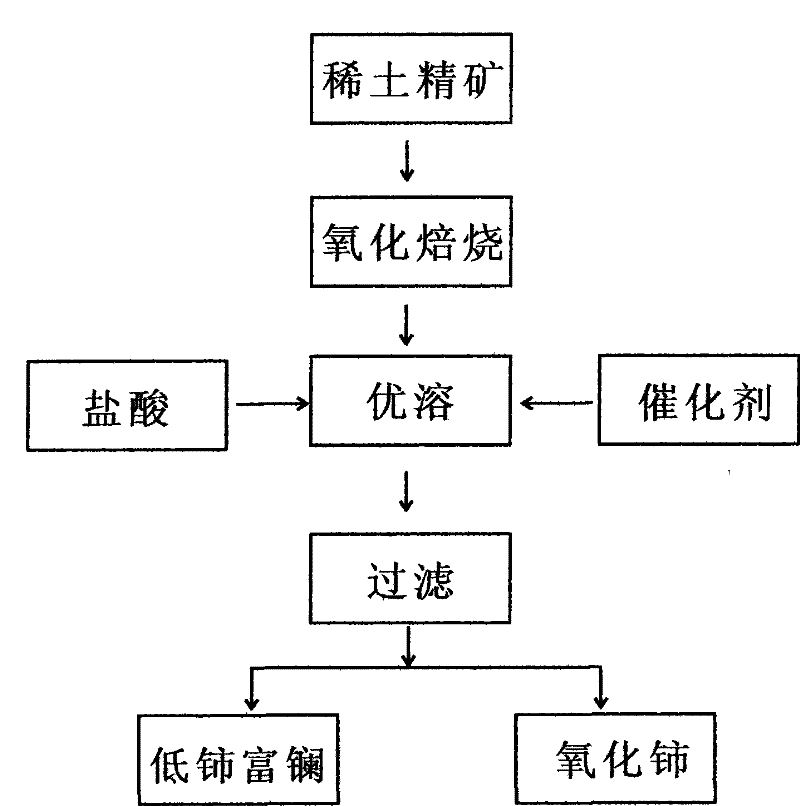

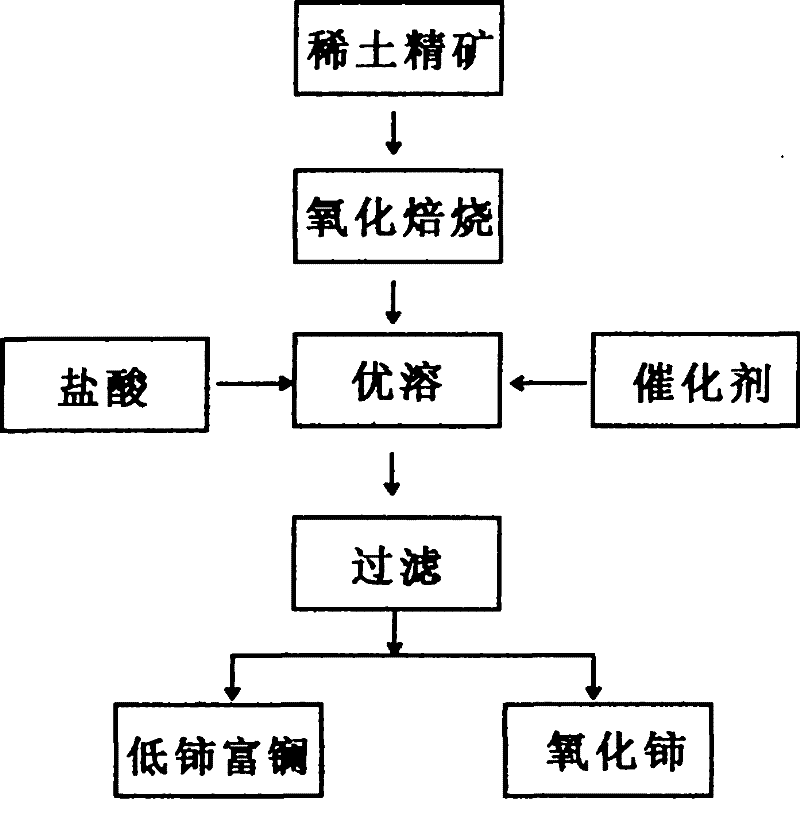

[0022] The one-step production method of cerium-less rare earth chloride and cerium fluoride comprises the following steps:

[0023] D. Oxidation roasting of rare earth concentrate;

[0024] E. Perform dilute hydrochloric acid to dissolve the rare earth concentrate after oxidation and roasting, and add a catalyst;

[0025] F. Filter and separate the slag and solution after excellent dissolution.

[0026] The catalyst is 5% sulfuric acid, and the addition amount is 0.8% of the hydrochloric acid consumption, and the addition method is to add first or simultaneously, after excellent dissolution, the content of cerium in the dilute chloride diagram with less cerium and rich lanthanum is 6-18%, which is rich in lanthanum. The content of cerium in cerium slag is not less than 93%.

[0027] A catalyst is added in the dilute hydrochloric acid dissolving process to make cerium participate in the reaction. Using the principle of preferential complexation of fluorine, the cerium and fl...

specific Embodiment 2

[0028] The one-step production method of cerium-less rare earth chloride and cerium fluoride comprises the following steps:

[0029] G. Oxidation roasting of rare earth concentrate;

[0030] H. Carry out dilute hydrochloric acid to the rare earth concentrate after oxidizing and roasting, and add a catalyst;

[0031] 1. Filtration and separation of slag and solution after excellent dissolution.

[0032] The acid catalyst is 8% nitric acid, the addition amount is 0.8% of the hydrochloric acid consumption, and the addition method is to add first or at the same time. The content of cerium in cerium slag is not less than 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com