Manufacturing process of a heavy-duty hyperboloid curved steel box girder

A production process and hyperboloid technology, which is applied in the field of heavy irregular steel structure production, can solve the problems of irregular groove cutting and unqualified welding seam inspection, etc., and achieve the effect of reducing repeated processes, cutting specifications, and increasing the proportion of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

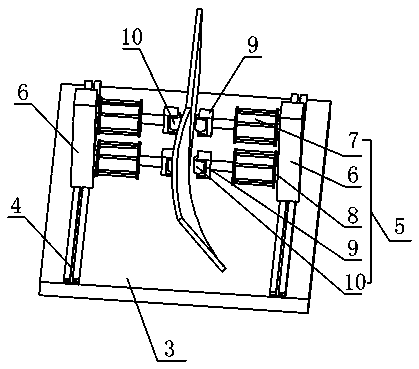

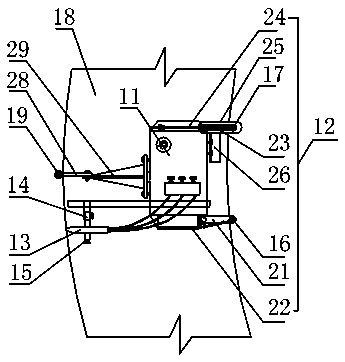

[0042] A manufacturing process of a heavy-duty hyperboloid arc steel box girder, the hyperboloid arc steel box girder is a frame-shaped steel structure comprising two hyperboloid arc-shaped webs 1 and two hyperboloid arc-shaped wing plates 2 , the manufacturing process of the hyperboloid arc steel box girder includes three-dimensional modeling, blanking, twist forming, hyperboloid arc steel box girder assembly, assembly deformation correction, hyperboloid arc steel box girder welding and welding deformation correction Seven steps, specifically:

[0043] (1) Three-dimensional modeling, establish a three-dimensional model of the hyperboloid arc steel box girder in ATUOCAD, and obtain the length, width, central axis, hyperboloid radian, three-dimensional coordinate value of the turning point of the hyperboloid arc steel box girder and slope according to the three-dimensional model mouth and other data;

[0044] (2) Cutting the material, input the length and width data set in the...

Embodiment 2

[0062] A manufacturing process of a heavy-duty hyperboloid arc steel box girder, the hyperboloid arc steel box girder is a frame-shaped steel structure comprising two hyperboloid arc-shaped webs 1 and two hyperboloid arc-shaped wing plates 2 , the manufacturing process of the hyperboloid arc steel box girder includes three-dimensional modeling, blanking, twist forming, hyperboloid arc steel box girder assembly, assembly deformation correction, hyperboloid arc steel box girder welding and welding deformation correction Seven steps, specifically:

[0063] (1) Three-dimensional modeling, the same as in embodiment 1;

[0064] (2) blanking, same as embodiment 1;

[0065] (3) Twist forming, same as embodiment 1;

[0066] (4) Hyperboloid curved steel box girder assembly, the distance between adjacent tire frame units 38 is 300mm, and other processes are the same as in Embodiment 1;

[0067] (5) Correction of assembly deformation, the same as in Example 1;

[0068] (6) Welding of ...

Embodiment 3

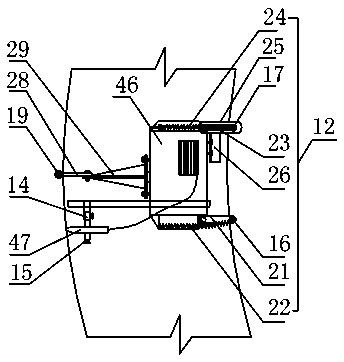

[0072] A manufacturing process of a heavy-duty hyperboloid arc steel box girder, the hyperboloid arc steel box girder is a frame-shaped steel structure comprising two hyperboloid arc-shaped webs 1 and two hyperboloid arc-shaped wing plates 2 , the manufacturing process of the hyperboloid arc steel box girder includes three-dimensional modeling, blanking, twist forming, hyperboloid arc steel box girder assembly, assembly deformation correction, hyperboloid arc steel box girder welding and welding deformation correction Seven steps, specifically:

[0073] (1) Three-dimensional modeling, the same as in embodiment 1;

[0074] (2) blanking, same as embodiment 1;

[0075] (3) Twist forming, same as embodiment 1;

[0076] (4) Hyperboloid arc-shaped steel box girder assembly, the distance between adjacent tire frame units 38 is 200mm, and other processes are the same as in embodiment 1;

[0077] (5) Correction of assembly deformation, the same as in Example 1;

[0078] (6) Welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com