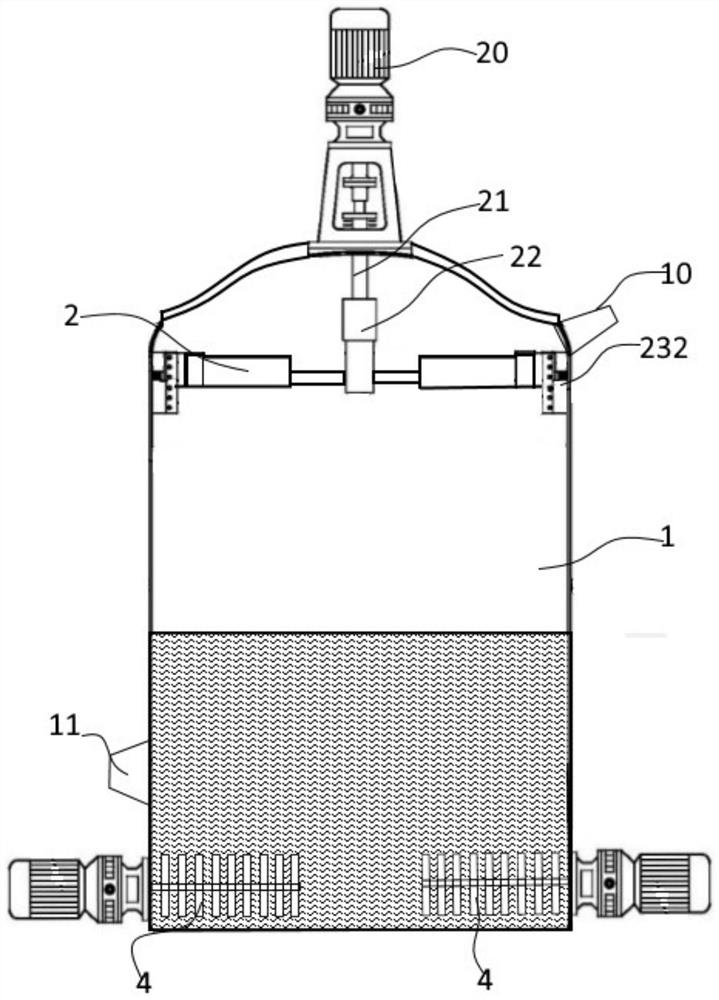

Paint spraying wastewater treatment system and treatment method thereof

A wastewater treatment system and wastewater technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unfavorable pass rate, increase in circulating water consumption, and pump blockage. , to achieve the effect of reducing repetitive processes and improving efficiency

- Summary

- Abstract

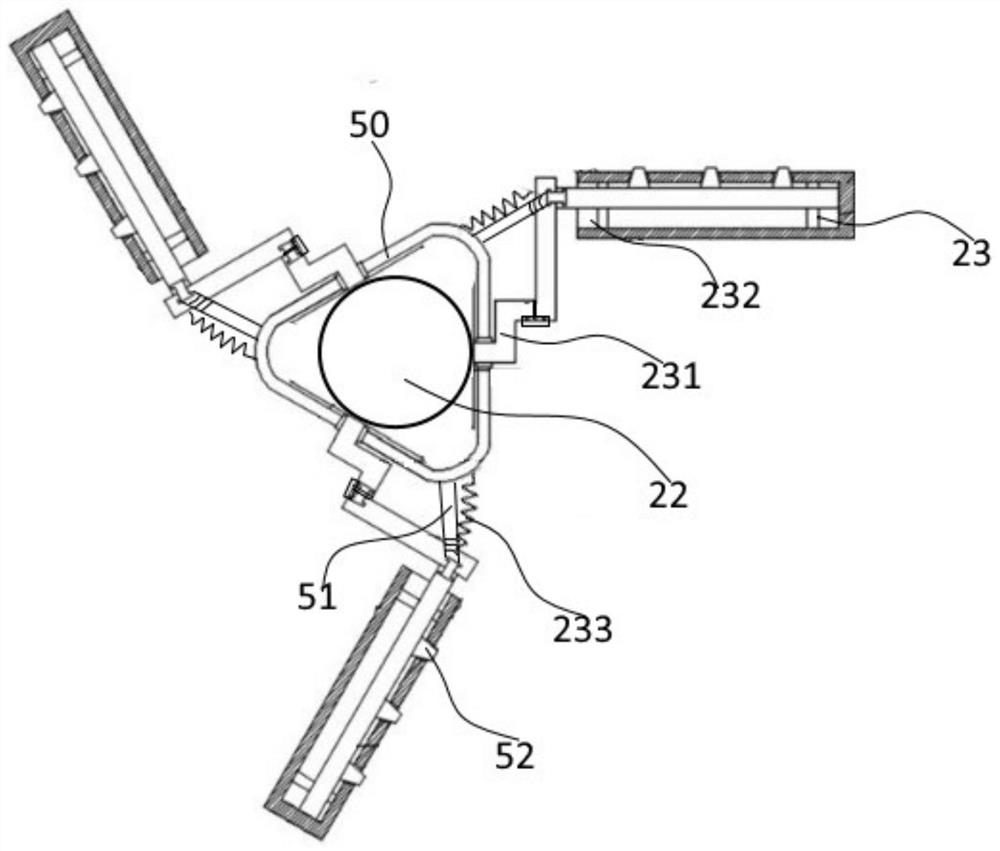

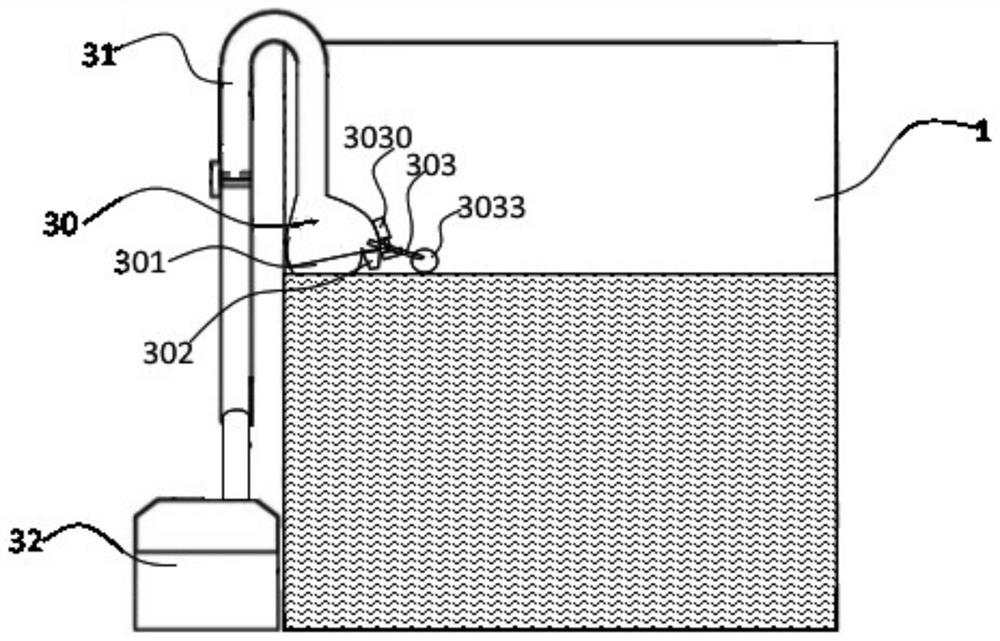

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0034] The applicant found that the initial purification of paint waste water, after first adding paint suspending agent in the sedimentation tank, forms a condensate floating on the water surface in the paint waste water and then collects it and continuously completes the treatment of paint waste water through circular purification; paint suspending agent Dissolve the paint molecules in the water, and remove the sticking and emulsifying properties. Due to the variety of spray paints used in the paint spraying process in the spray booth, and the paint dilution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com