Method for preparing polyethylene wax containing phenoxy group at chain end by thermal degradation

A technology of polyethylene wax and phenoxy group, which is applied in the field of preparation of polyethylene wax containing phenoxy group at the chain end and polyethylene wax containing phenoxy group at the chain end, which can solve the problems of high cost, large solvent consumption and complicated process , to achieve the effect of increasing polarity and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

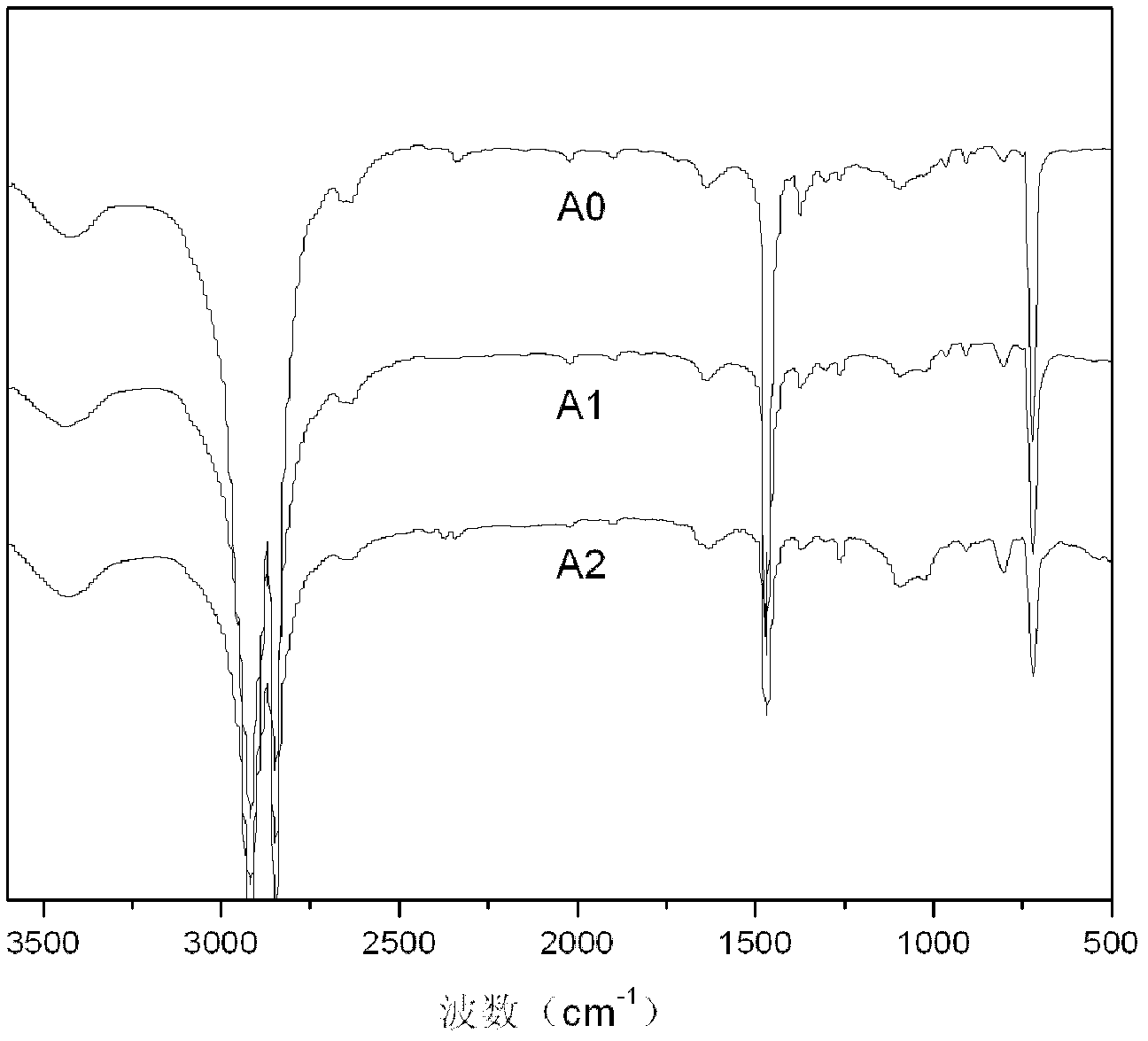

Image

Examples

Embodiment 1

[0025] 200 parts of low-density polyethylene pellets and 2 parts of hydroquinone mixed with 200 parts of industrially produced low-density polyethylene pellets with a weight-average molecular weight of 100,000 are added into the autoclave, and nitrogen gas is introduced to make the pressure in the autoclave rise to 0.6MPa. Then raise the temperature in the autoclave to 200°C, start stirring and control the stirring rate to 50rpm; continue to heat up to 330°C and then keep the temperature constant, and keep the pressure in the autoclave below 1Mpa (if the pressure exceeds 1Mpa, you can lightly open the exhaust valve decompression) reaction for 0.5h, stop heating; when the temperature in the kettle drops to 190°C, stop stirring, wait until the temperature in the kettle drops to 160°C, open the exhaust valve, open the reaction kettle, take out the melt, and drop it in the air to After room temperature, it was pulverized to obtain the product.

Embodiment 2

[0027] 200 parts of industrially produced high-density polyethylene pellets with a weight-average molecular weight of 170,000 and 4 parts of hydroquinone are mixed and added to the autoclave, and then nitrogen gas is introduced to make the pressure in the autoclave rise to 0.6MPa. Then raise the temperature in the autoclave to 205°C, start stirring and control the stirring rate to 60rpm; continue to heat up to 340°C and then keep the temperature constant, and keep the pressure in the autoclave below 1Mpa (if the pressure exceeds 1Mpa, you can lightly open the exhaust valve decompression) for 3 hours, stop heating; stop stirring when the temperature in the kettle drops to 195°C, and when the temperature in the kettle drops to 170°C, open the exhaust valve, open the reaction kettle, take out the melt, and cool it down to room temperature in the air Then pulverize to obtain the product.

Embodiment 3

[0029] 200 parts of industrially produced high-density polyethylene pellets with a weight-average molecular weight of 300,000 and 2 parts of hydroquinone are mixed and added to the autoclave, and then nitrogen gas is introduced to make the pressure in the autoclave rise to 0.5MPa. Then raise the temperature in the autoclave to 200°C, start stirring and control the stirring rate to 50rpm; continue to heat up to 330°C and then keep the temperature constant, and keep the pressure in the autoclave below 1Mpa (if the pressure exceeds 1Mpa, you can lightly open the exhaust valve decompression) for 2 hours, stop heating; when the temperature in the kettle drops to 190°C, stop stirring, wait until the temperature in the kettle drops to 165°C, open the exhaust valve, open the reaction kettle, take out the melt, and cool it down to room temperature in the air Then pulverize to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com