Automatic aligning and grinding method for drill bit

A grinding method and drill bit technology, which is applied to boring machine/drilling machine components, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of effectively saving construction costs, difficulty in combining processing speed and efficiency, large configuration space, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

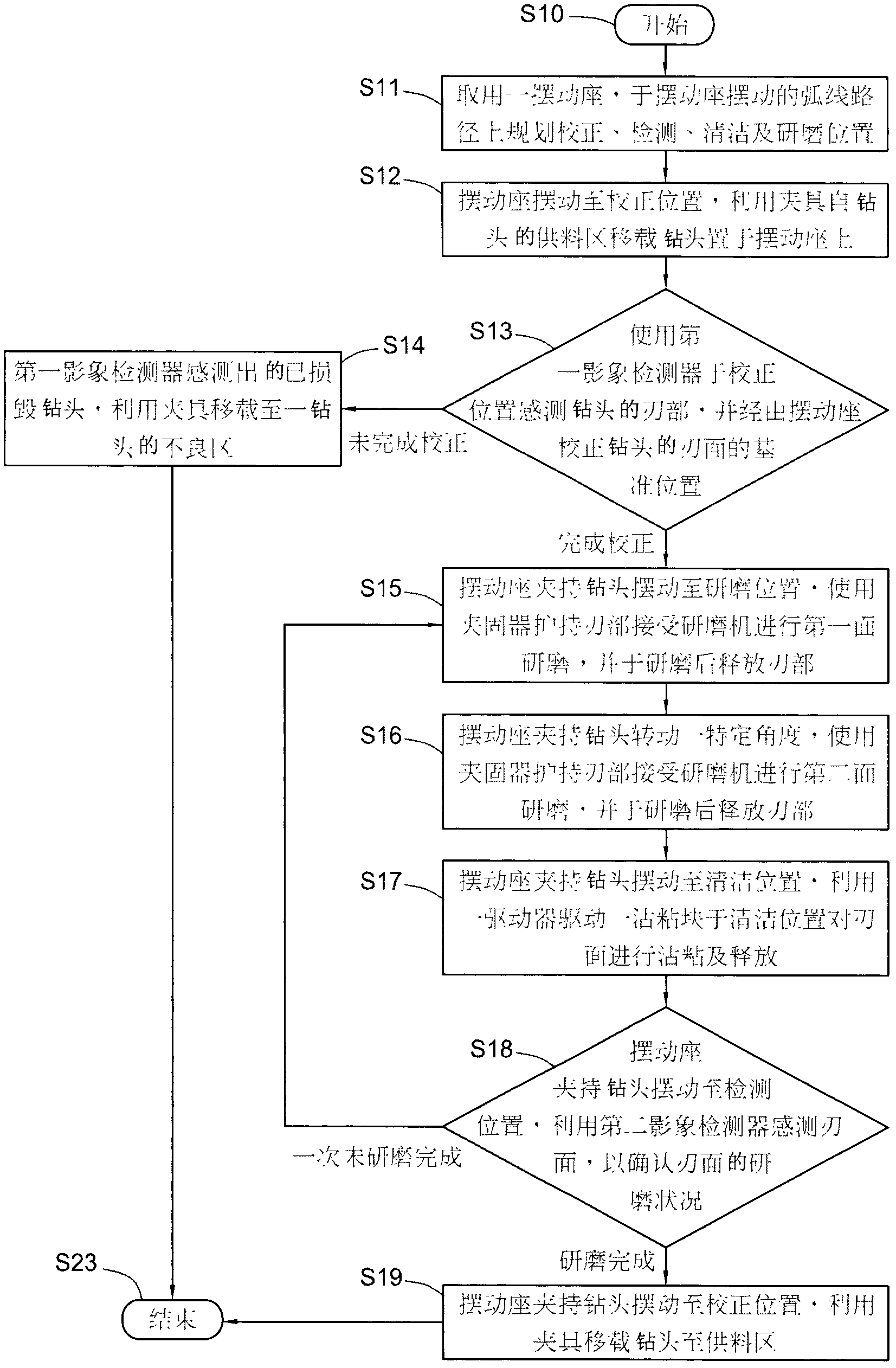

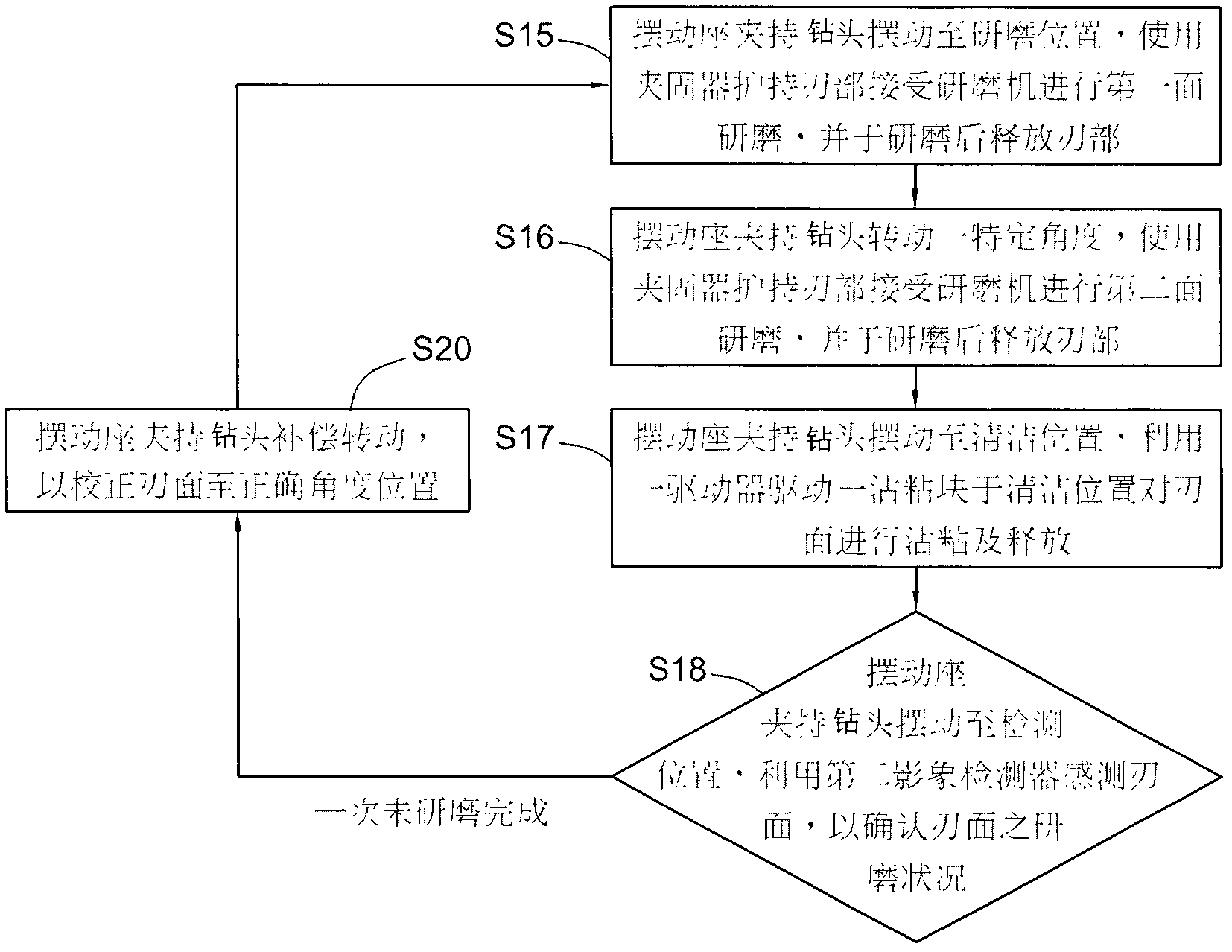

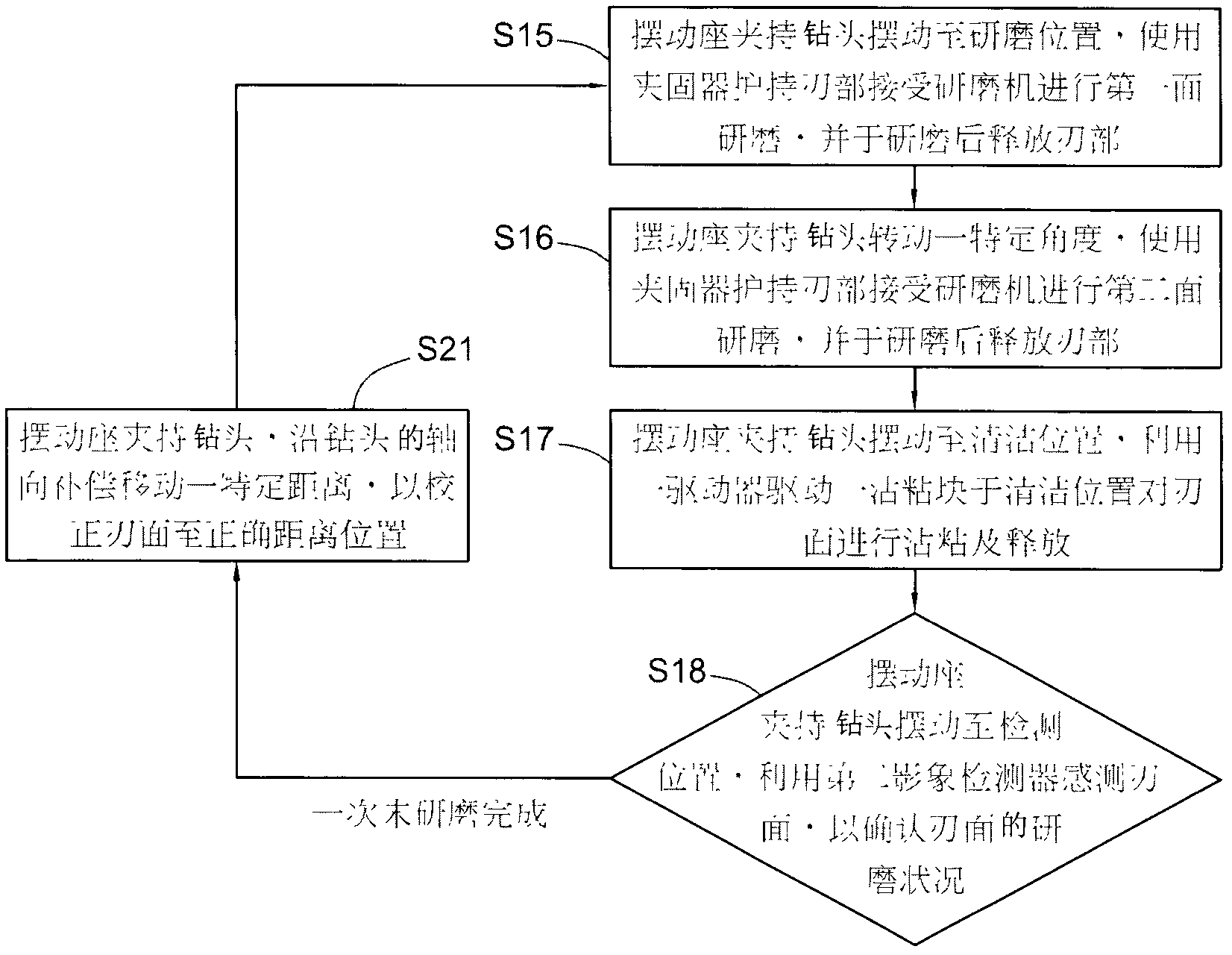

[0037] first look figure 1 Shown, reveals the flow chart of the preferred embodiment of the present invention, and coordinates figure 2 and image 3 Illustrate the automatic alignment grinding method of drill bit of the present invention, comprise following implementation steps:

[0038] In step S10, start to implement the method of the present invention.

[0039] In step S11, a swing base 1 is used, and the swing base 1 is pivotally placed near the feeding area 7 of a drill bit 9, and several drill boxes 90 capable of accommodating a plurality of drill bits 9 are arranged in the feeding area 7 , the drill bit 9 can be taken out by the drill box 90 in this implementation, and put back into the original drill box 90 after grinding, so the feed area 7 can become the feed end and outlet of the drill bit 9 in this implementation. The material end; the swing base 1 can actually be a rotary pneumatic cylinder, and the top of the rotary pneumatic cylinder has a clamping part 11 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com