Processing method and boring clamp of front axle shell for excavator

A processing method and technology of excavators, which are applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy generation of waste, low processing efficiency, and troublesome clamping, so as to ensure processing accuracy and improve work efficiency. , Fast clamping and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

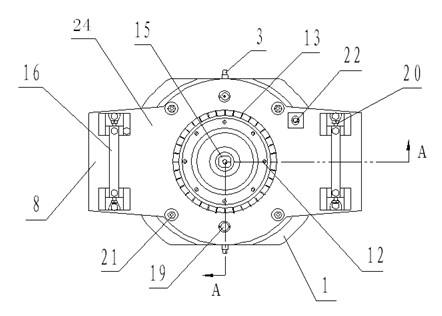

[0018] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but it is not intended to limit the present invention.

[0019] The embodiment of the present invention: a method for processing the front axle housing of an excavator. The front axle housing of the excavator is processed on an ordinary boring machine. First, a base with a horizontal reference surface is fixed on the worktable of the boring machine, and then the The end surface of the large hole on the front axle housing of the excavator is used as the positioning reference surface during processing. The end surface of the large hole on the front axle housing of the excavator used as the positioning reference surface is attached to the horizontal reference surface on the base, and then passed After the clamping device installed on the base clamps and fixes the front axle housing of the excavator, the shaft holes at both ends of the front axle housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com