Method for evaluating emulsifying capacity of emulsifiers for emulsified explosives

A technology of emulsifying ability and emulsifying explosives, applied in the directions of flow characteristics, measuring devices, instruments, etc., can solve the problems of unusability, contradictory test results of high and low temperature cycle method, long investigation time of conductance method, etc., and achieves high reliability and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

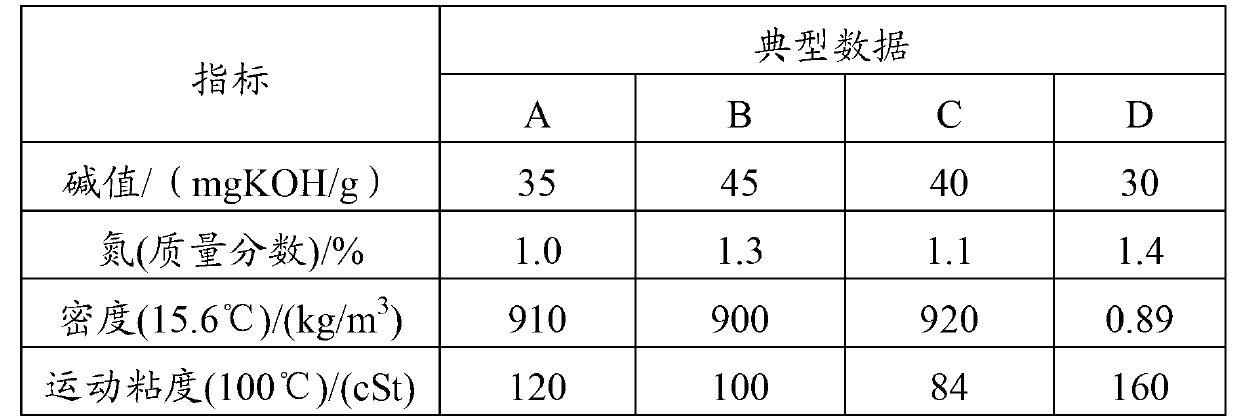

[0037] The emulsifying ability of the commercially available polymer emulsifiers A, B, C, and D was evaluated by the method for evaluating the emulsifying ability of the emulsifier according to the present invention. Polymer emulsifier A is R102 emulsifier produced by Jinzhou Huifa Tianhe Chemical Co., Ltd., polymer emulsifier B is LZ2820 emulsifier produced by Lubrizol, and polymer emulsifier C is produced by Beijing General Research Institute of Mining and Metallurgy BEF emulsifier, polymer emulsifier D is T154 emulsifier produced by Jinzhou Petrochemical No. 6 Plant. The relevant technical indicators of polymer emulsifiers A, B, C, and D are shown in Table 1 below.

[0038] Table 1

[0039]

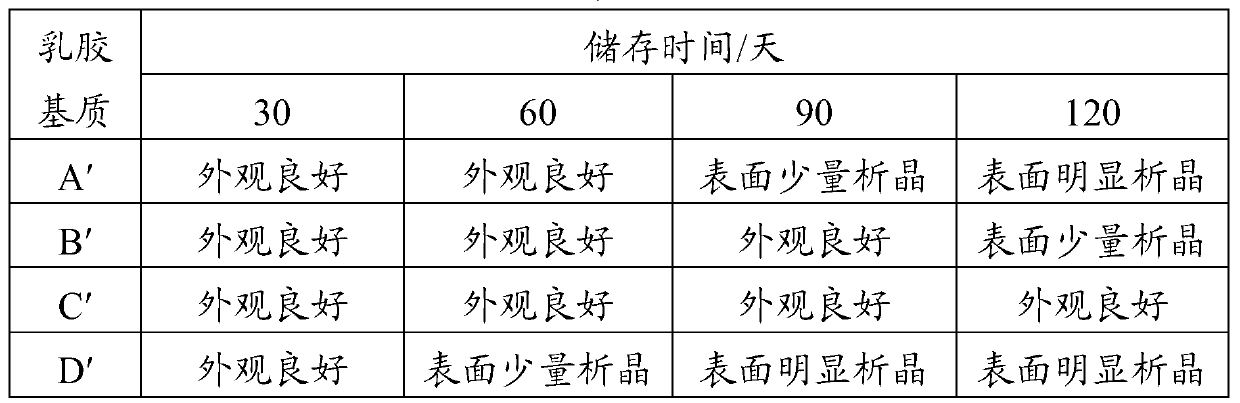

[0040] For each of polymer emulsifiers A, B, C, and D, 5 kg of latex base was prepared. Each latex matrix contains 72.9wt% of ammonium nitrate, 20wt% of water, 0.1wt% of citric acid, 2wt% of emulsifier, 5wt% of 46# machinery oil in the national standard GB / T7631.13-1995.

[0041]...

example 2

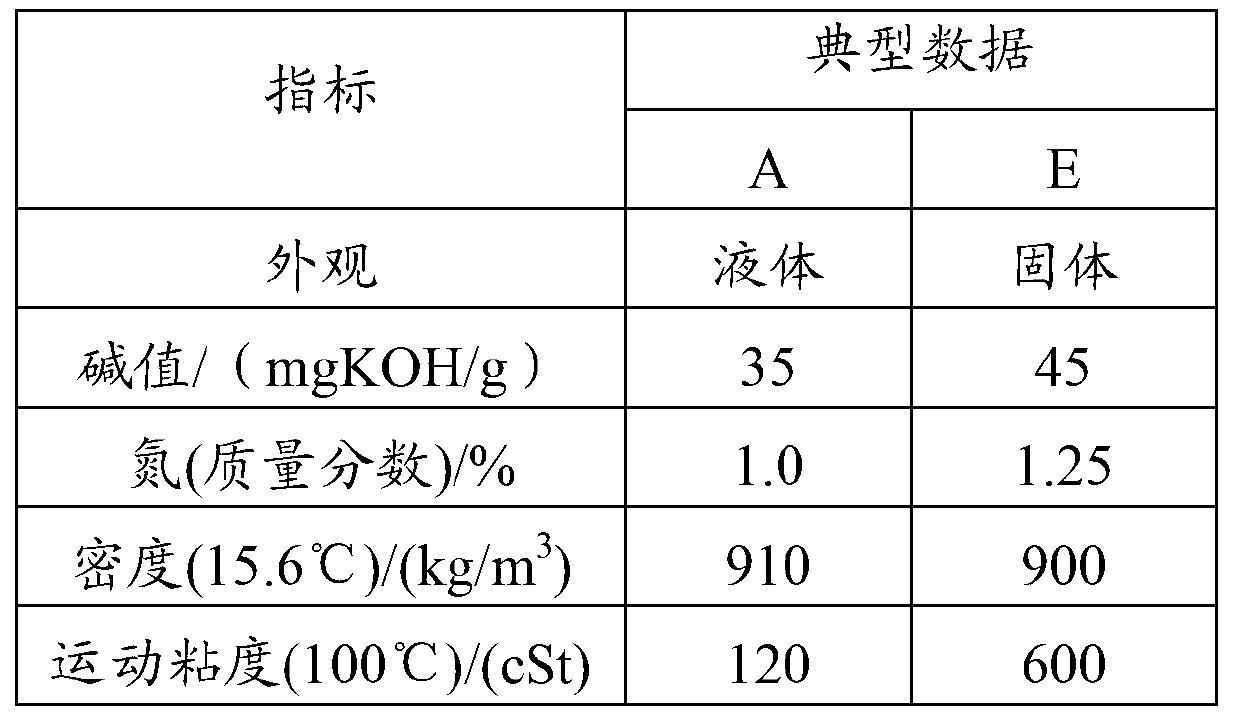

[0058] The emulsifying ability of the commercially available polymer emulsifiers A and E was evaluated using the method for evaluating the emulsifying ability of an emulsifier according to the present invention. Polymer emulsifier A is the R102 emulsifier produced by Jinzhou Huifa Tianhe Chemical Co., Ltd. used in example 1, and polymer emulsifier E is the solid T152 emulsifier produced by Jiangsu Hongguang Chemical Co., Ltd. The relevant technical indicators of polymer emulsifiers A and E are shown in Table 5 below.

[0059] table 5

[0060]

[0061] Since polymer emulsifiers A and E differ greatly in appearance, polymer emulsifier A is liquid, and polymer emulsifier E is solid, so first perform pre-separation of active ingredients on polymer emulsifier E and prepare a product with uniform active ingredient content Steps for testing samples.

[0062] Using the silica gel column separation method, take 500 grams of polymer emulsifier E and put it into the silica gel colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com