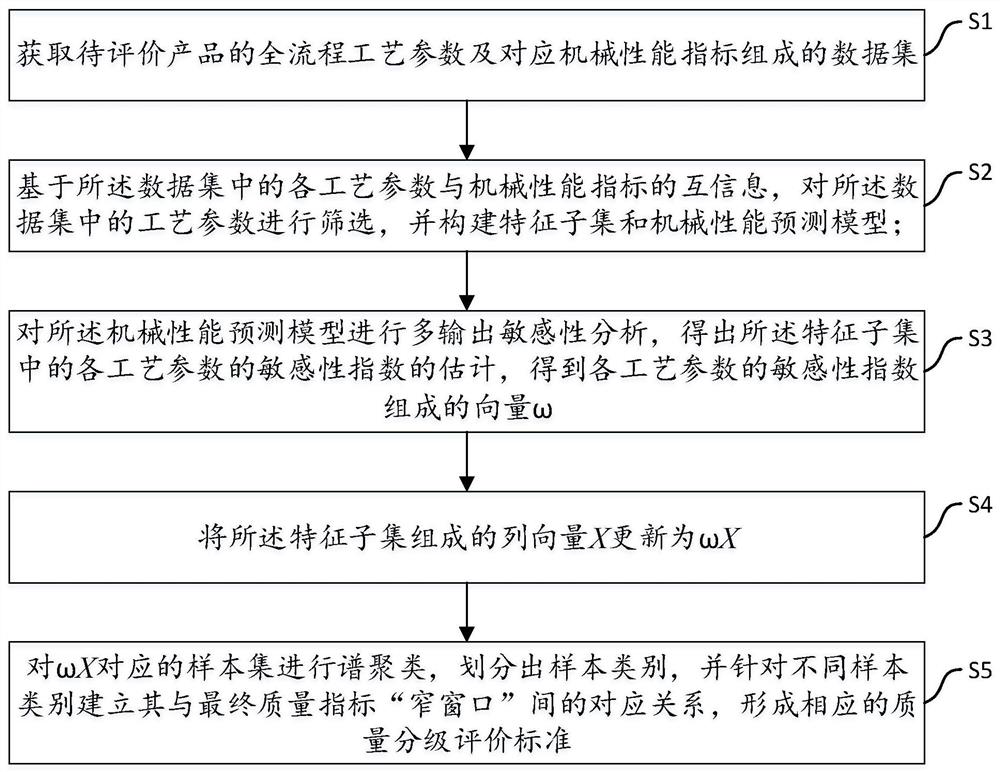

Product quality grading evaluation standard design method and system

An evaluation standard and product quality technology, applied in the field of product quality classification evaluation standard design method and system, can solve problems such as difficult to directly and accurately reflect the quality index level of process parameters in the whole process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

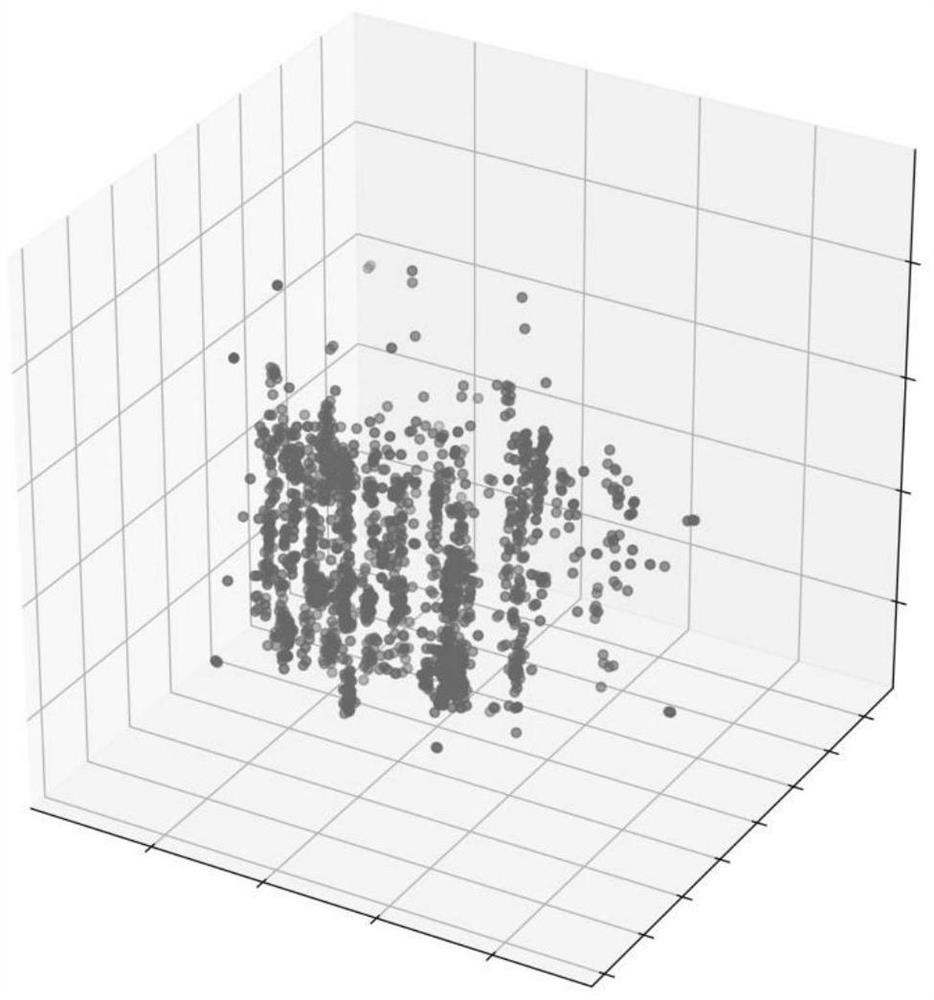

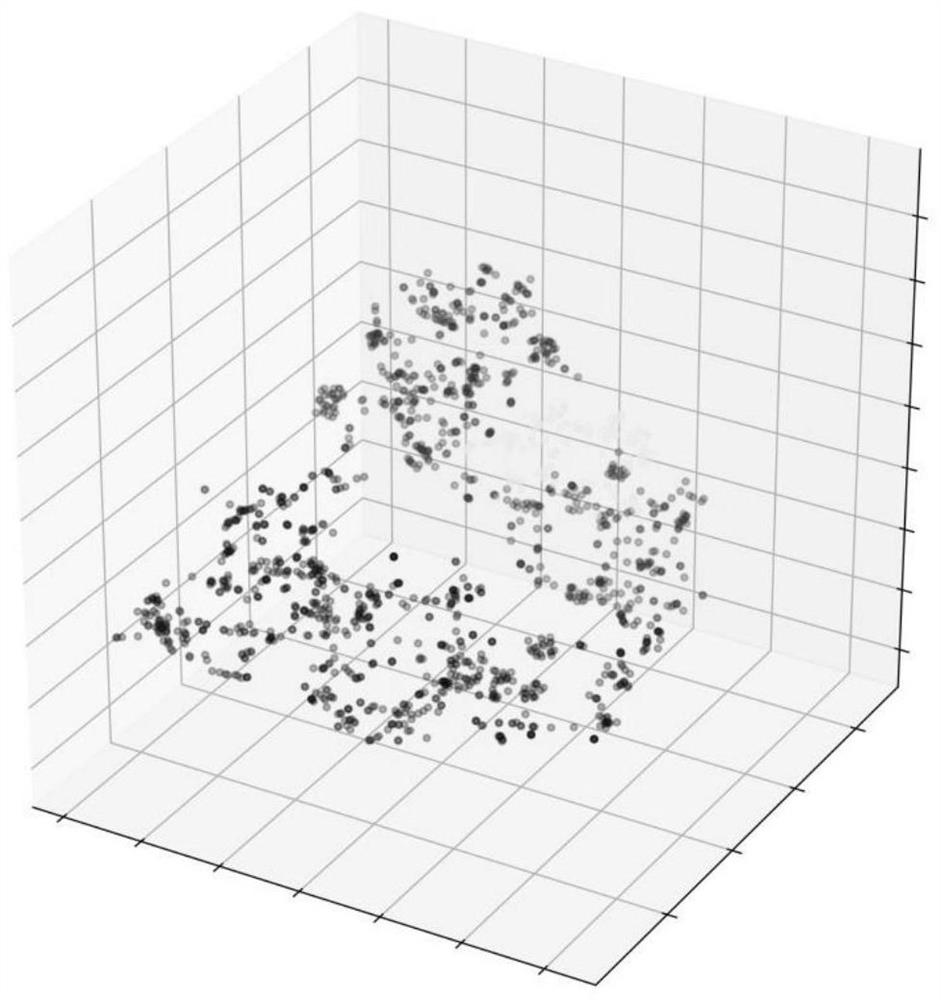

[0063] This embodiment provides a product quality classification evaluation standard design method, which is mainly used for product quality classification evaluation management in the steel manufacturing process. This embodiment defines the column vector composed of feature subsets after feature selection of production process parameters as X, Quality indicators of steel products: the column vector of lower yield strength, tensile strength and elongation is Y, and the mechanical properties prediction model of cold-rolled products is constructed as Y=f(X), where f is the trained MSVR model or other A multi-output nonlinear prediction model that satisfies prediction accuracy. Since the upstream process parameters of iron and steel products are genetically influenced by multiple processes to the final product quality, and the process parameters have different scales, it is impossible to evaluate the influence of the process parameters on the final product quality by directly clus...

no. 2 example

[0114] This embodiment provides a product quality classification evaluation standard design system, and the product quality classification evaluation standard design system includes the following modules:

[0115] The data set acquisition module is used to obtain the data set composed of the whole process process parameters of the product to be evaluated and the corresponding mechanical performance indicators;

[0116] A feature subset and mechanical property prediction model building module is used to screen the process parameters in the data set based on the mutual information of each process parameter and the mechanical property index in the data set, and construct the feature subset and mechanical property prediction model; wherein, the input of the mechanical performance prediction model is a vector composed of process parameters, and the output is a vector composed of mechanical performance indicators;

[0117] The process parameter sensitivity index vector acquisition m...

no. 3 example

[0123] This embodiment provides an electronic device, which includes a processor and a memory; wherein, at least one instruction is stored in the memory, and the instruction is loaded and executed by the processor to implement the method of the first embodiment.

[0124] The electronic device may vary greatly due to different configurations or performances, and may include one or more processors (central processing units, CPU) and one or more memories, wherein the memory stores at least one instruction, so The instructions described above are loaded by the processor and perform the following steps:

[0125] S1, obtaining a data set consisting of process parameters of the whole process of the product to be evaluated and corresponding mechanical performance indicators;

[0126] S2, based on the mutual information of each process parameter and the mechanical performance index in the data set, screen the process parameters in the data set, and construct a feature subset and a mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com