Large-scale circulating fluid bed boiler with buffering bed

A circulating fluidized bed and buffer bed technology, which is applied in the direction of fluidized bed combustion equipment, combustion type, fuel burned in a molten state, etc., can solve the fundamental problem of "turning over bed, coking in the furnace, threatening the safe and stable operation of the boiler" To achieve the effect of improving hydrodynamic safety, uniform heating, and consistent heating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. The same reference numerals denote the same elements or elements having the same function throughout the drawings. The embodiments described below by referring to the figures are exemplary.

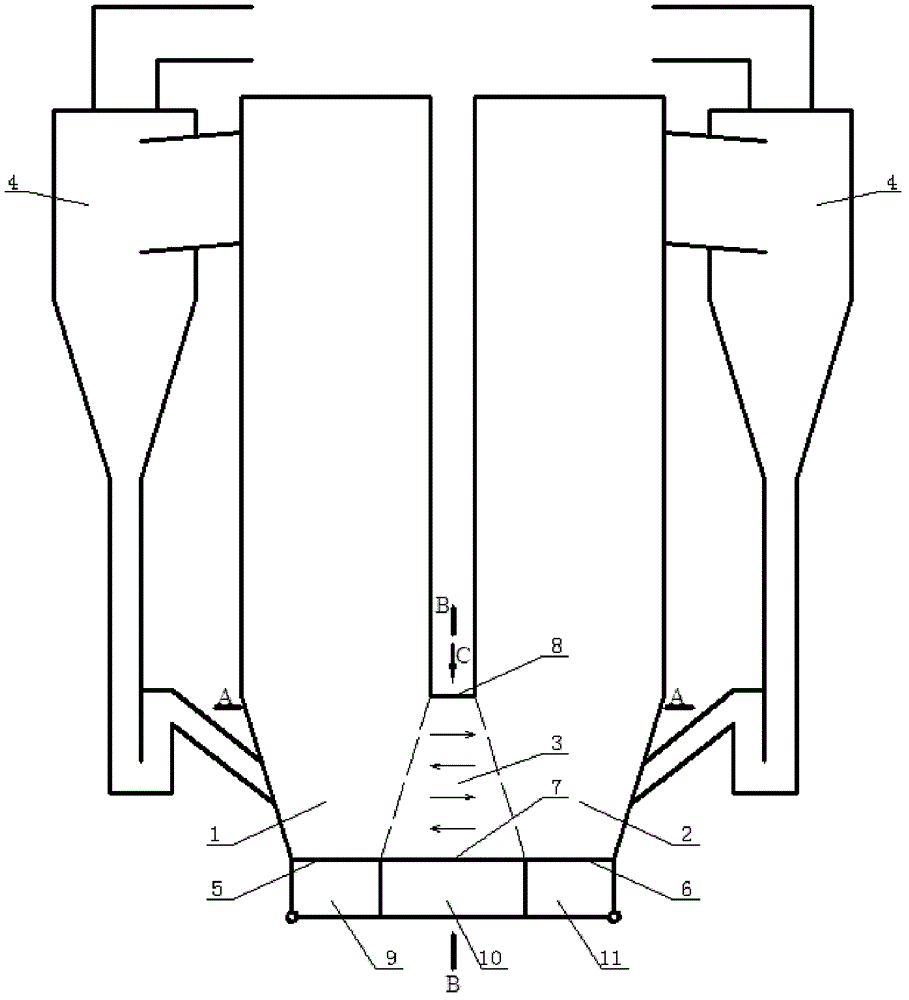

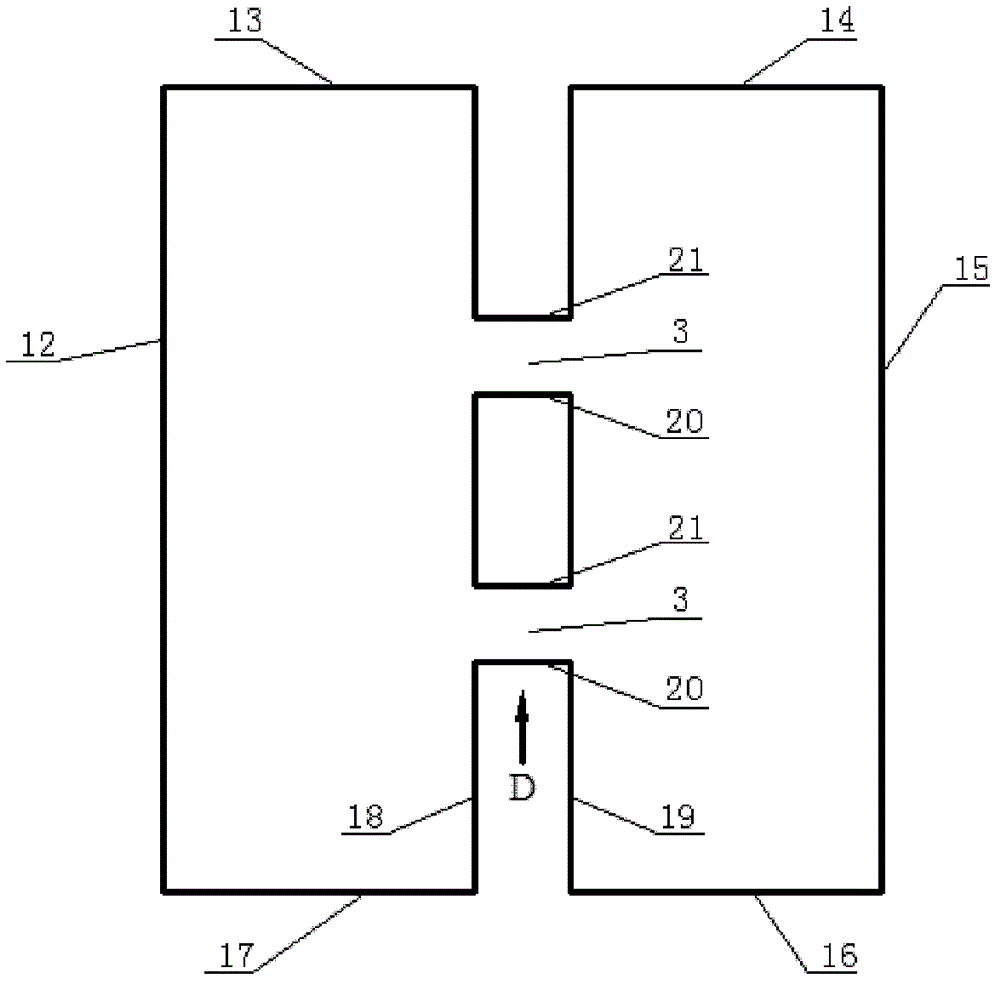

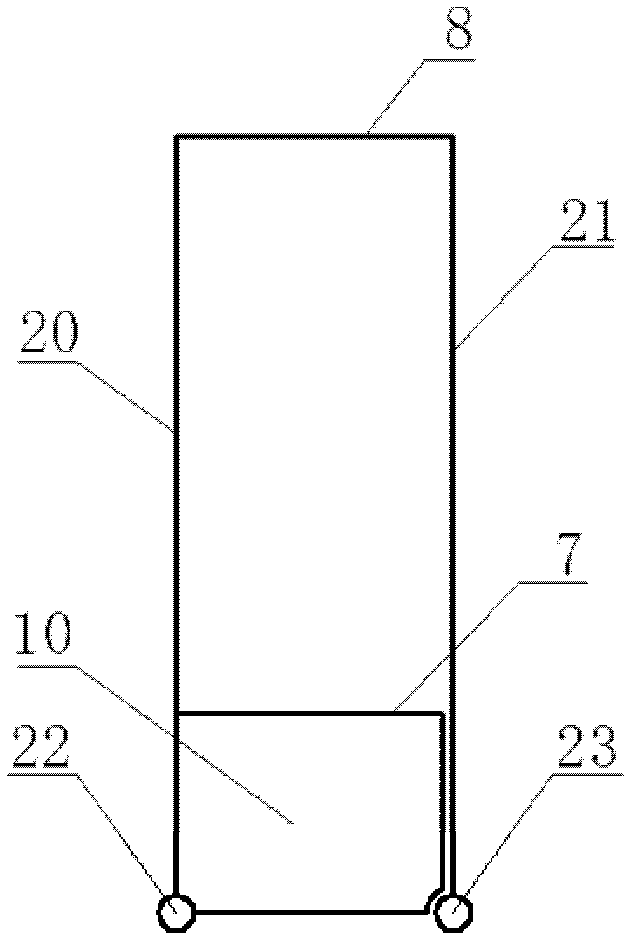

[0018] figure 1 , figure 2 and image 3 It is a structural schematic diagram of an embodiment of a large-scale circulating fluidized bed boiler with a buffer bed provided by the present invention. The large-scale circulating fluidized bed boiler includes: the first furnace 1, the second furnace 2, the cyclone separator 4 and at least one buffer bed 3 arranged in parallel adjacently, and the buffer bed is uniform along the depth direction between the first furnace and the second furnace Setting; the cyclone separator is symmetrically arranged on the outside of the two furnaces, the upper part of the first furnace 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com