Fuel oil/gas boiler for reducing emission of nitric oxides and method

A gas-fired boiler, nitrogen oxide technology, applied in burners, combustion equipment, greenhouse gas reduction and other directions, can solve the problems of reduced combustion efficiency, reduced boiler rated output and thermal efficiency, complex systems, etc., to reduce nitrogen oxide emissions, The effect of no increase in operating cost and wide stability range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

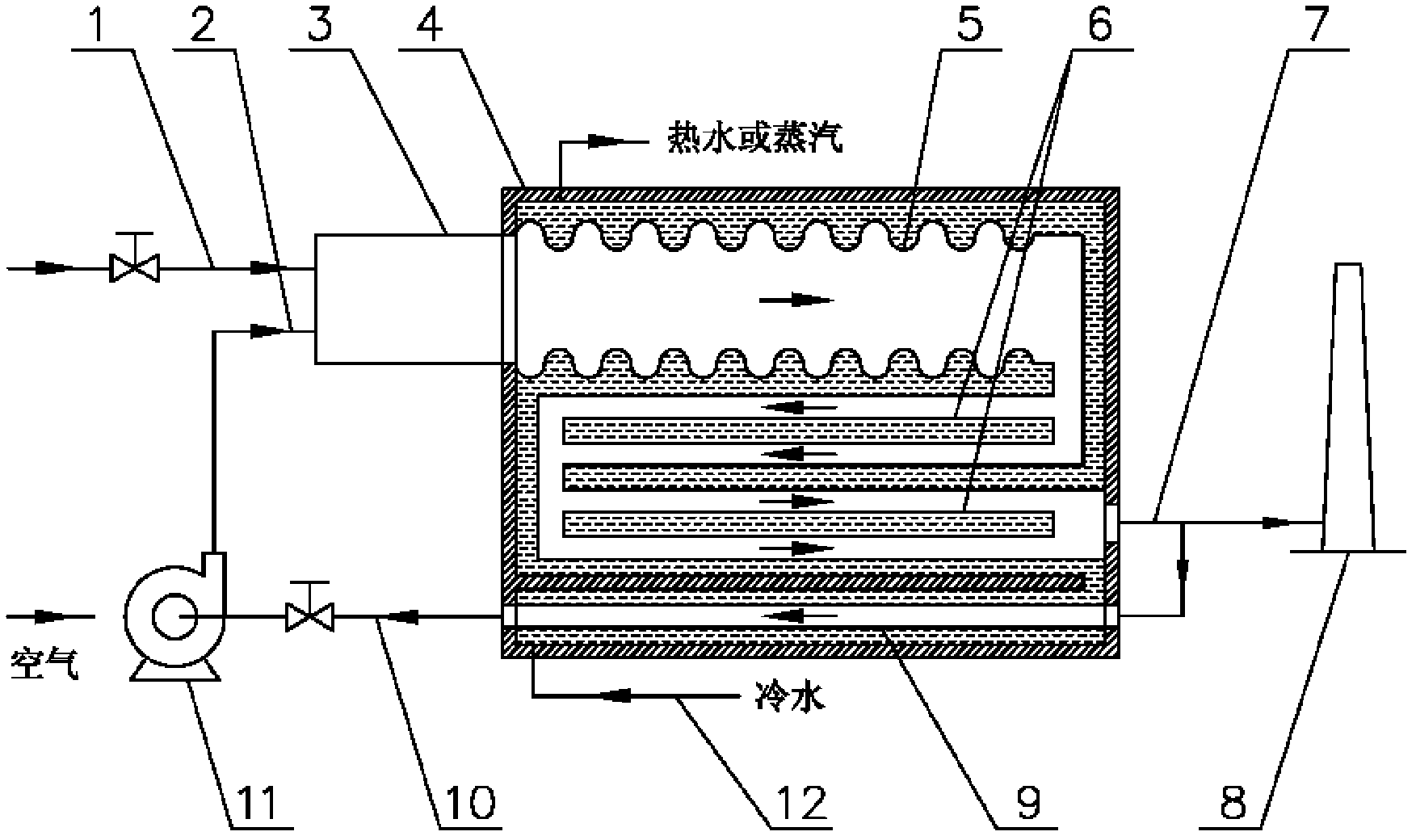

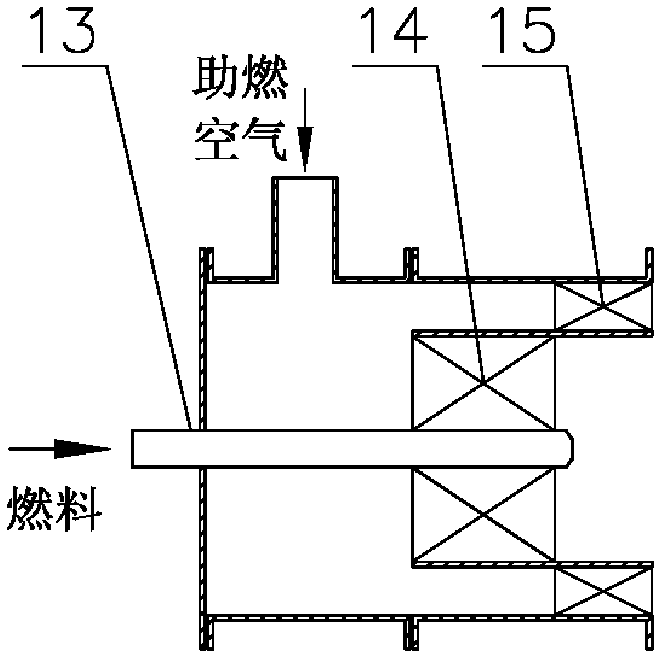

[0022] figure 1 As the first embodiment of the present invention, the fuel and combustion-supporting air enter the low-nitrogen burner 3 through the fuel pipe 1 and the combustion-supporting air pipe 2 to mix and burn, and generate high-temperature flue gas at 1180-1290°C (flow rate 1250-1360m 3 / MW) sequentially flows through the radiation heating surface 5 and the convection heating surface 6 in the boiler body 4 (the flow direction of the air flow is shown by the arrow in the figure), heating the water in the boiler, while the flue gas is cooled, and the radiation heat exchange surface 6 of the boiler The area is 5.7~7.1m 2 / MW, the area of convective heat transfer surface 7 is 22.9~28.6m 2 / MW. 15% to 25% of the low-temperature flue gas from the boiler is mixed with fresh air and used as the combustion-supporting air of the low-nitrogen burner 3. The temperature of the high-temperature flue gas produced is 190°C to 300°C lower than that of ordinary boilers, and the flo...

Embodiment approach

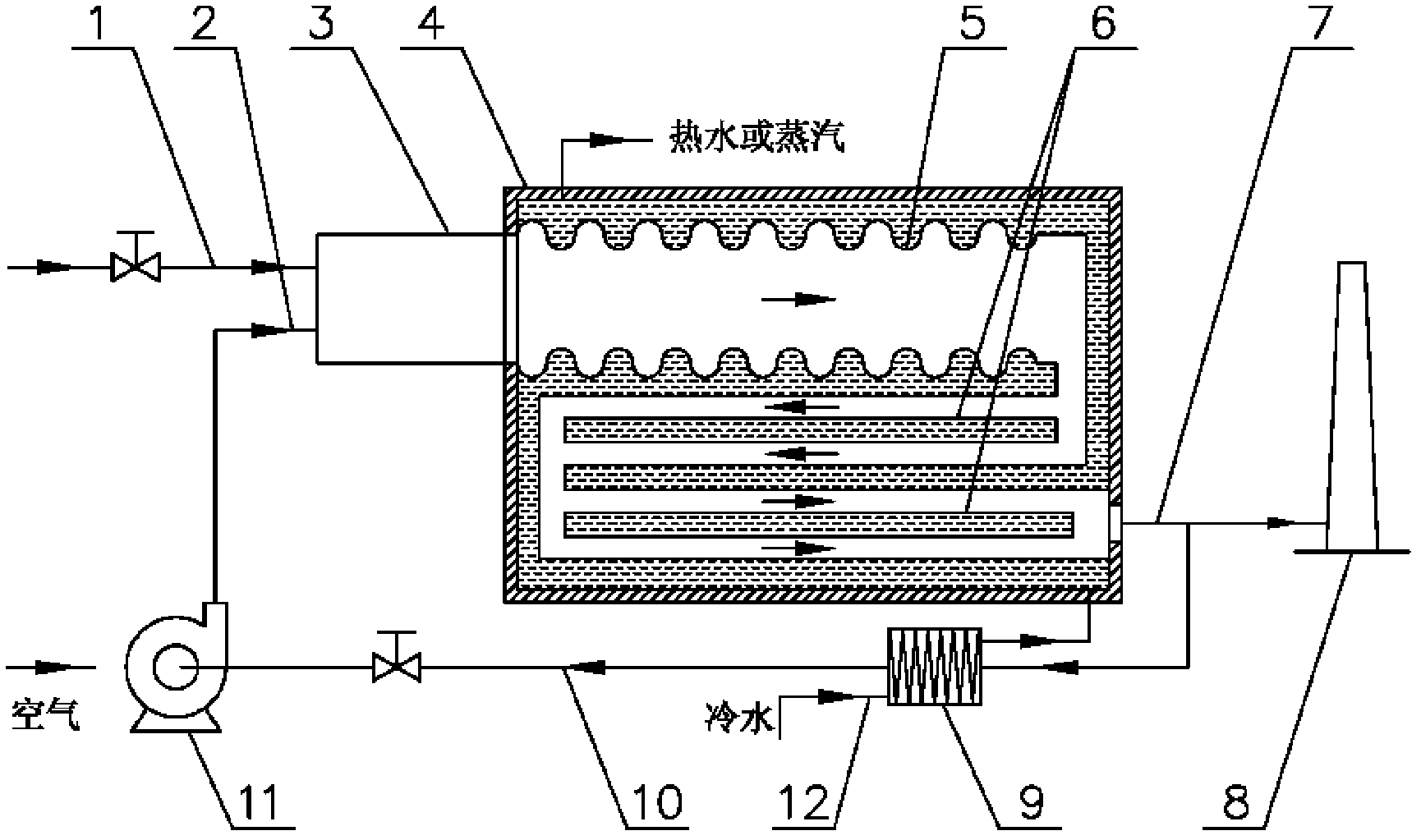

[0026] figure 2It is the second embodiment of the present invention. Compared with the first embodiment, the circulating flue gas cooler 9 in this embodiment is placed outside the boiler body 4 . The cold water in the water inlet pipe 12 first cools the external circulating flue gas cooler 9 and then enters the boiler body 4 to ensure the cooling effect of the circulating flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com