Hydraulic safety valve of antifreezing oil storage tank

A technology for oil storage tanks and safety valves, applied in safety valves, balance valves, valve devices, etc., can solve problems such as increased viscosity of sealing oil, freezing of flame arresters, storage tank accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

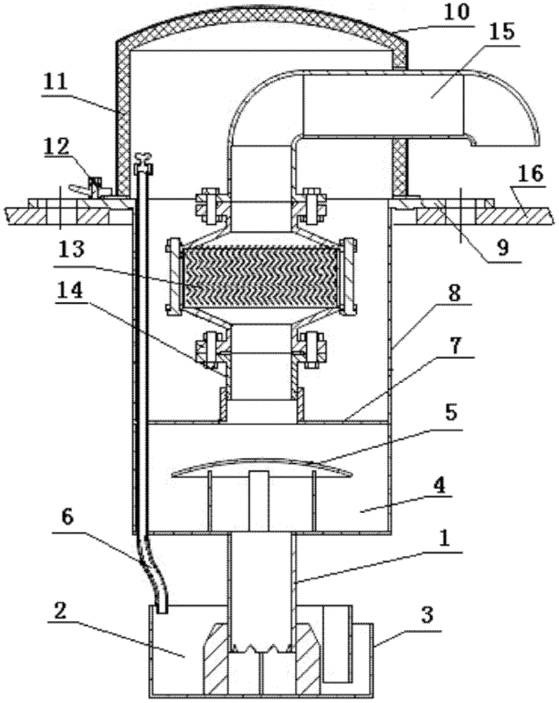

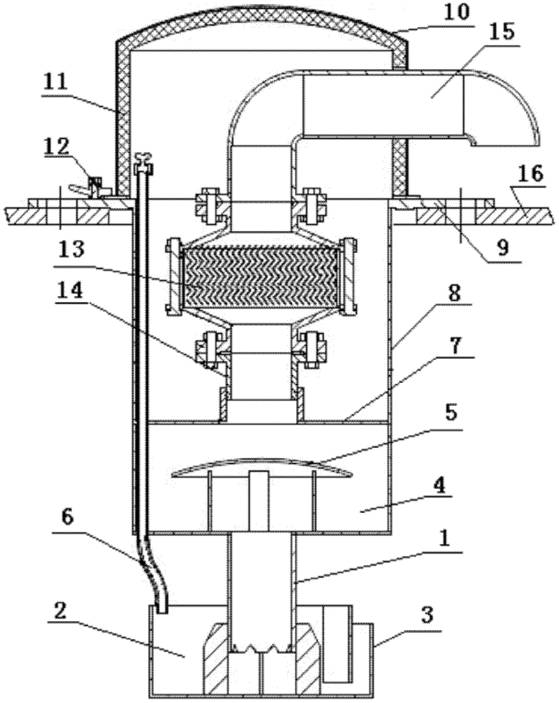

[0018] Embodiment: Taking a hydraulic safety valve of an antifreeze type petroleum storage tank with a total height of 1300mm, a diameter of 425mm, and an outer diameter of the mounting flange of 620mm as an example, further details will be given.

[0019] refer to figure 1 . Antifreeze hydraulic safety valve for petroleum storage tanks, mainly composed of central liquid conduit 1, liquid storage box 2, anti-shock plate 5, sealing liquid level detection device 6, cylinder body 8, mounting flange 9, windshield 10, flame arrester 13 , Connecting tube 14 and breathing tube 15 are formed.

[0020] The outer diameter of the mounting flange is 620mm, and a circular cylinder 8 is welded on the lower part of the center hole of the flat circular mounting flange 9. The inner diameter of the cylinder 8 is 415mm, the outer diameter is 425mm, and the height is 750mm. A 5 mm thick diaphragm 7 is welded in the cylinder body 8, and a fluid accumulation chamber 4 is formed between the diaphr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com