Heat storage temperature control device of solar disc-type Sterling engine

A technology of Stirling engine and temperature control device, which is applied in the direction of hot gas variable capacity engine device, machine/engine, mechanical equipment, etc. Efficiency, improve efficiency, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings and specific embodiments.

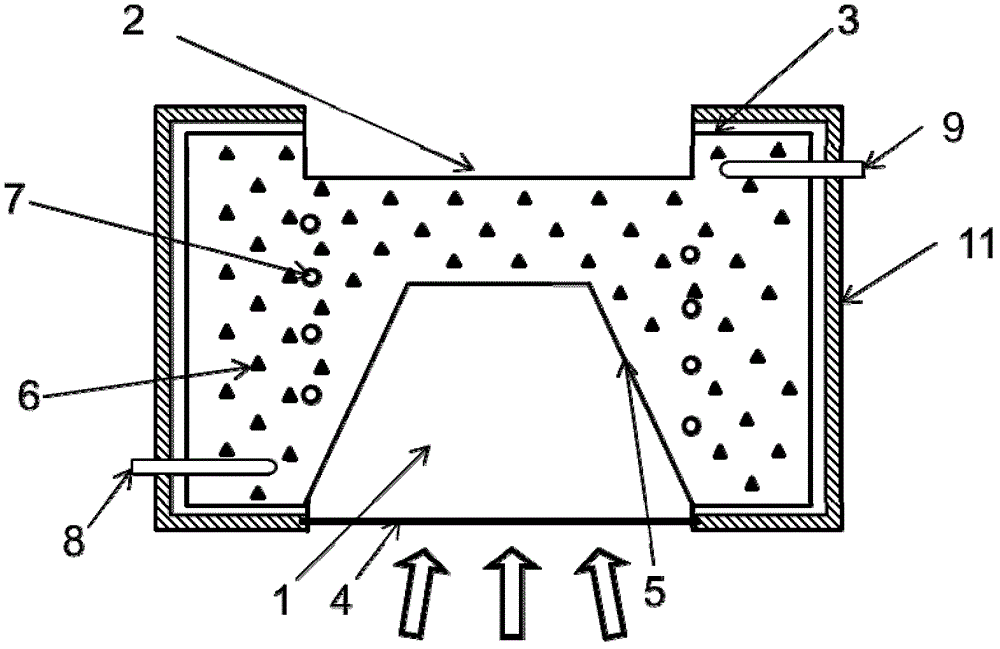

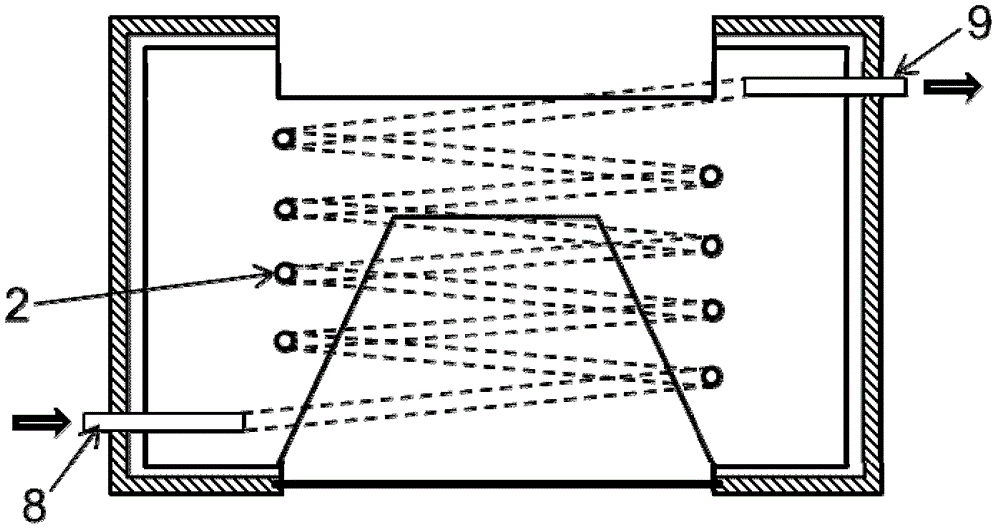

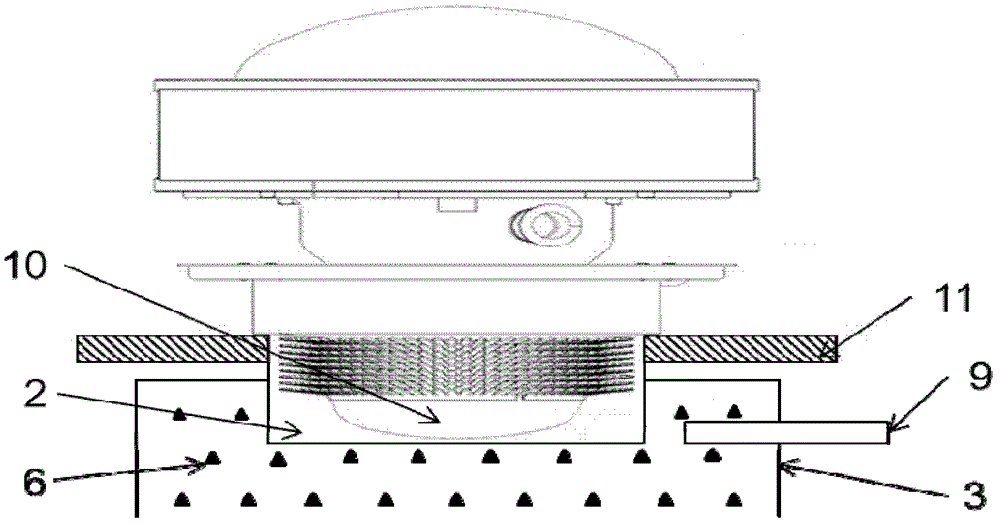

[0026] Such as figure 1 As shown, a heat storage and temperature control device for a solar dish type Stirling engine is cylindrical as a whole. One end of the cylindrical shape is provided with a solar heat collection cavity 1, and the other end is provided with a reserved cavity for the hot end of the Stirling engine 2. In the middle is a sealed box 3, the solar heat collection cavity 1 is in the shape of a cone, a transparent cover plate 4 is installed at the entrance, the transparent cover plate 4 is embedded in the thermal insulation layer 11, and the heat collection cavity inner shell 5 It is made of high-temperature heat-absorbing material, and the heat-collecting cavity 1 is sealed and evacuated into a vacuum. The sealed box 3 is equipped with heat storage materials 6 and heat exchange tubes 7, and the heat storage medium uses inorganic salt phase chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com