Integrated sludge treatment device

A treatment device and technology for sludge, which are applied in the fields of temperature control sludge treatment, dewatering/drying/concentrating sludge treatment, energy and waste water treatment, etc. The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

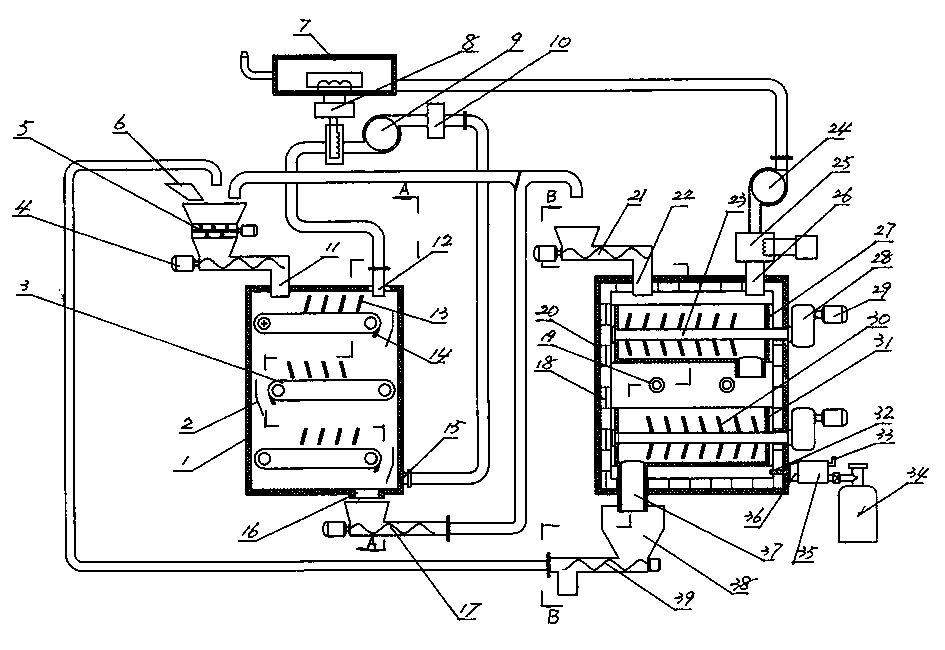

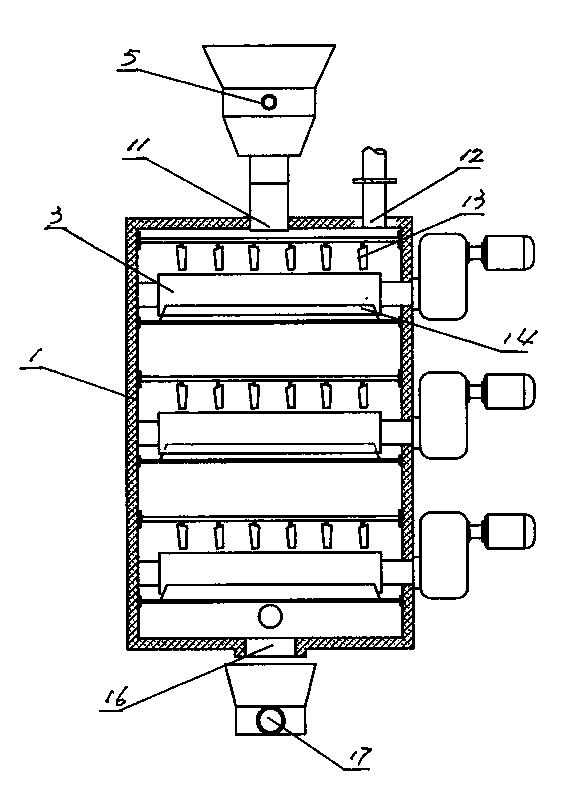

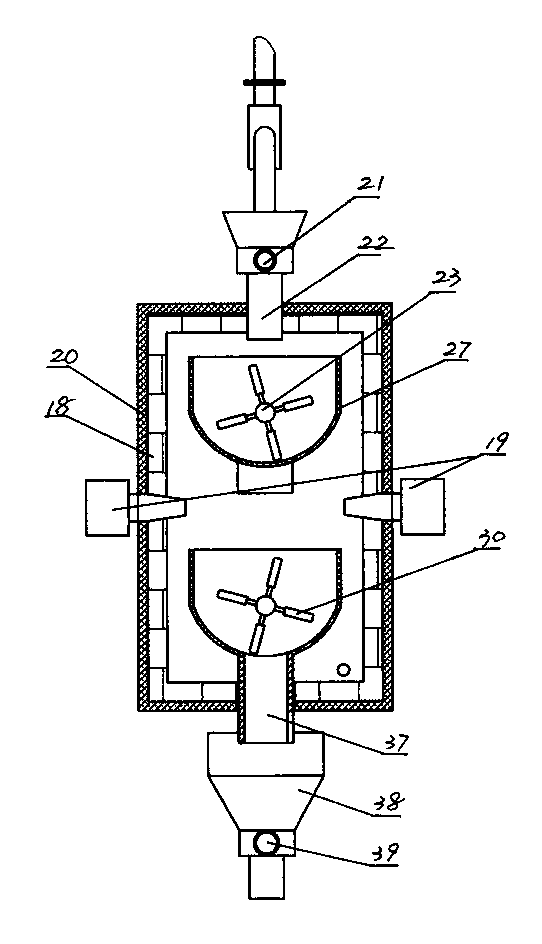

[0022] like figure 1 and figure 2 As shown, the sludge integrated treatment device of the present invention includes a drying part and a carbonization part. A first mud inlet 11 and a first air inlet 12 are processed on the top of the drying part containing the drying box 1, and a first mud outlet 16 and a first air outlet 15 are respectively processed on the bottom of the drying box 1 and on one side of the box bottom. . A heat collector is arranged above the drying box 1. The heat collector contains a box body 7 and a heat pump 8. The box body 7 is a closed box body. The inner side of the box bottom and the inner side of the four walls of the box body 7 are made of foam insulation materials For the insulation layer, the top plate of the box body 7 is made of light-transmitting glass, and the cold end of the heat pump 8 is placed in the box body 7 . In this way, in the daytime and when the sun is shining, the solar energy can be fully utilized to heat the cold end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com