Mould without hindering pearlstone slurry expansion

A body expansion and mold technology, applied in the field of building material production equipment, can solve the problems of perlite material structure integrity damage, finished product shape not too complicated, finished product strength decline, etc., to improve convenience, novel structure design, reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

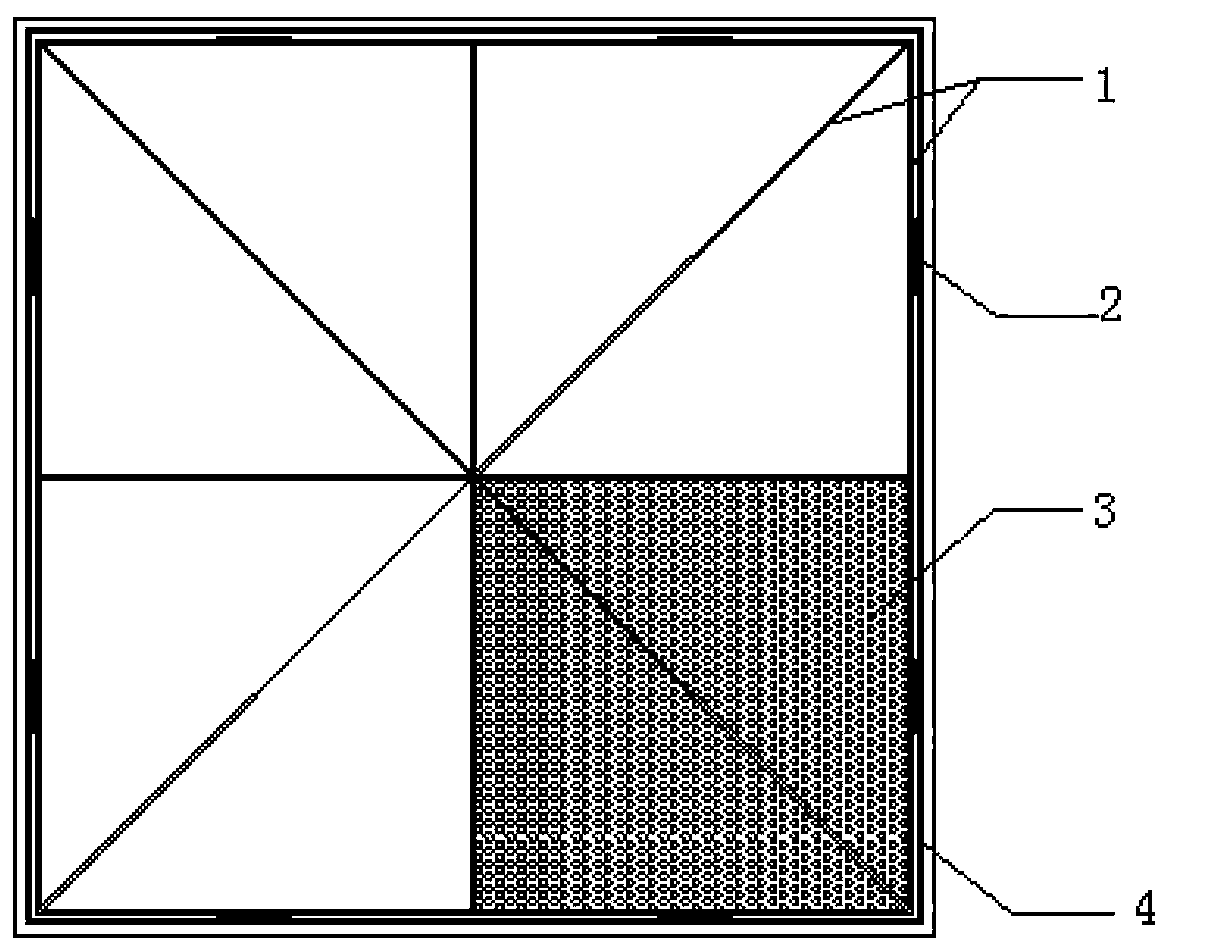

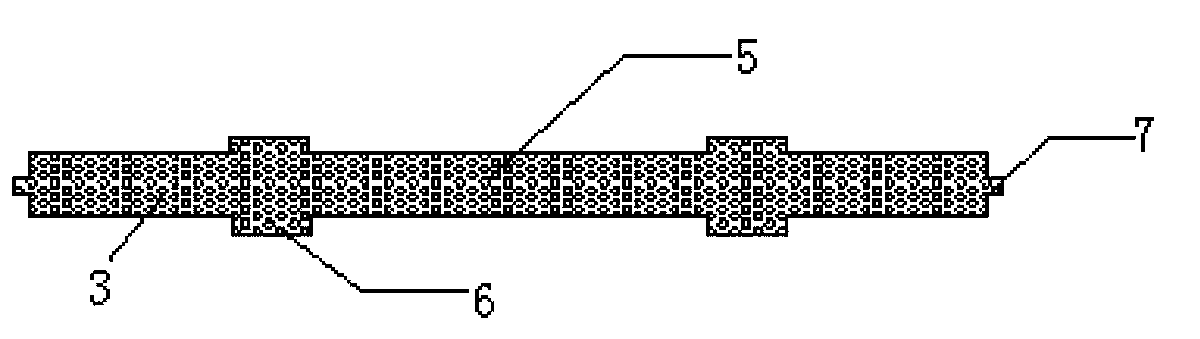

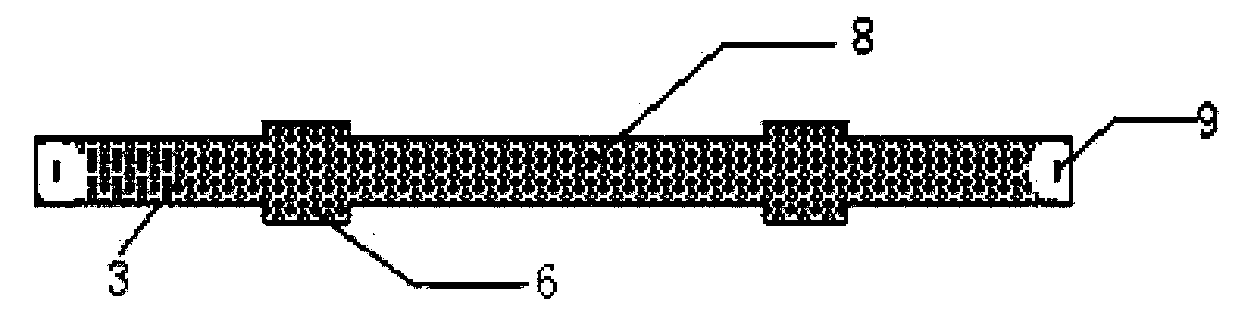

[0015] The main structure of the mold involved in this embodiment is composed of five functional parts: upper base plate, lower base plate, male wall plate, female wall plate and U-shaped card, including reinforcement rib 1, wall plate jack 2, vent hole 3, U Type card locking protrusion 4, male wall plate body 5, bottom plate plug 6, wall plate plug 7, female wall plate body 8, wall plate cross jack 9, hook 10, card slot 11 and U-shaped card body 12; the whole The mold consists of upper and lower bottom plates, the four side walls are male and female, and two wall plates are inserted on the sides of the upper and lower bottom plates in a butt joint type, and eight U-shaped clips are respectively buckled on the eight sides of the square mold. At the corresponding sides, the upper and lower bottom plates and the four walls of the mold are evenly dug with vent holes to facilitate the escape of gas during drying; There are densely distributed through-type exhaust holes 3 with a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com