Blade grinding machine for external conical surface of drill

An external cone surface and sharpening machine technology, which is used in drilling tool accessories, grinding workpiece supports, drilling/drilling equipment, etc. Meet the quality requirements and other problems, achieve the effect of intuitive man-machine operation interface, solving difficult angle adjustment, and bright grinding surface of drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

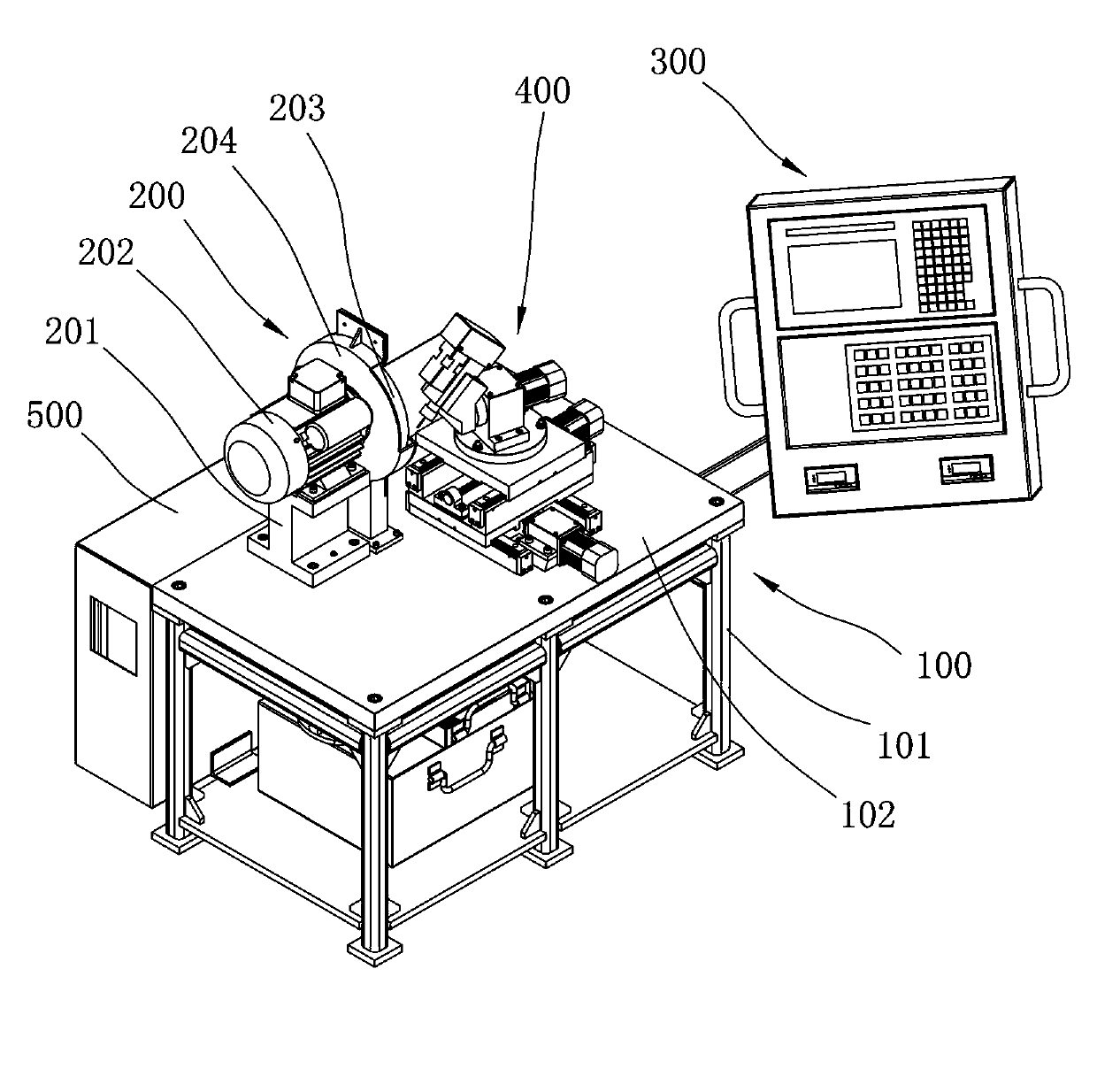

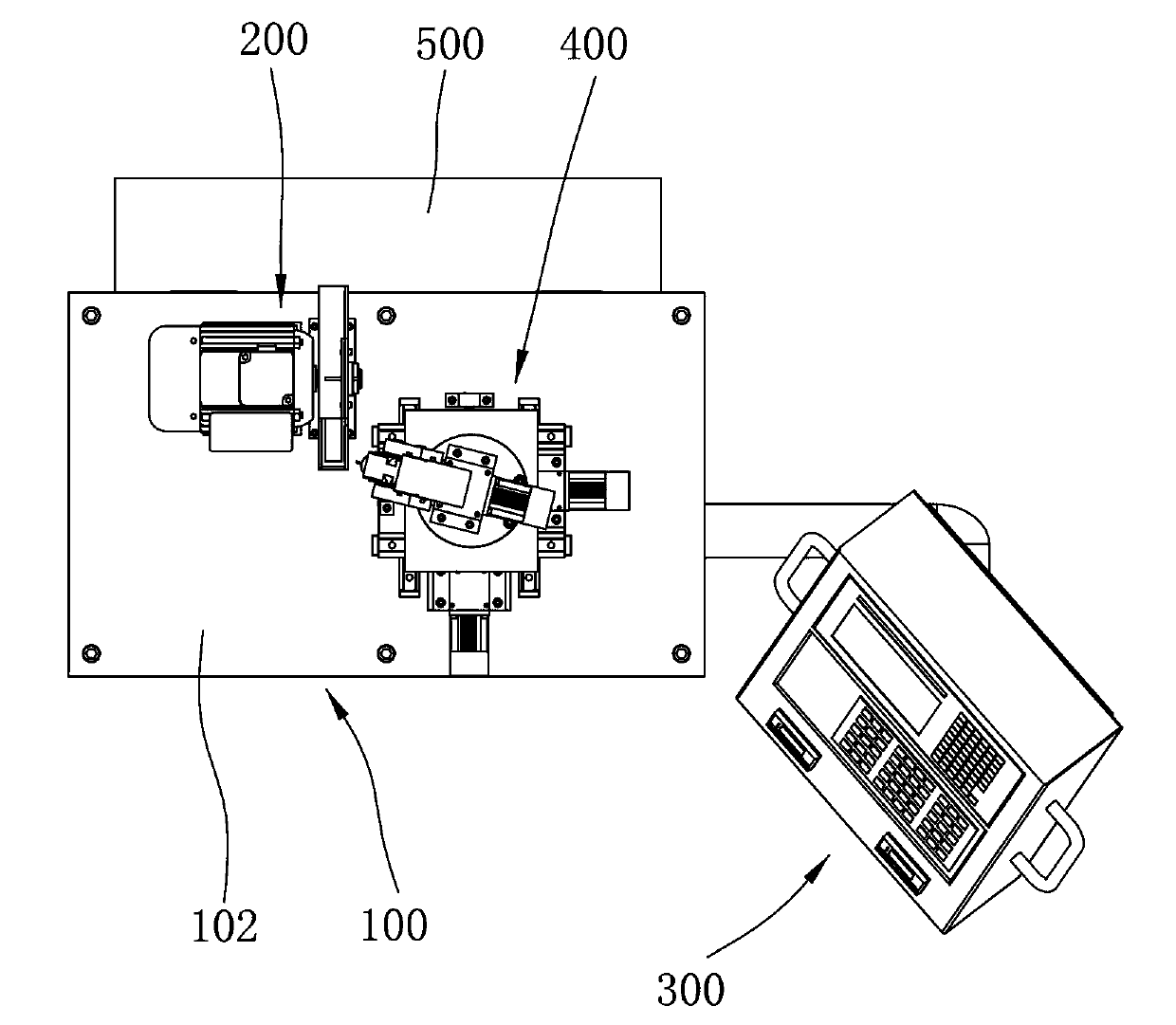

[0021] as attached figure 1 , attached figure 2 The shown drill bit outer cone sharpening machine includes a workbench 100 and a grinding device 200 installed on the workbench 100. A numerical control panel 300 is provided on one side of the workbench 100. According to the processed size, different programs are input on the numerical control panel 300 to control the rotation of the motor, so as to realize the precise grinding of the drill bit. The other side of the workbench 100 is also provided with an electrical control box 500 .

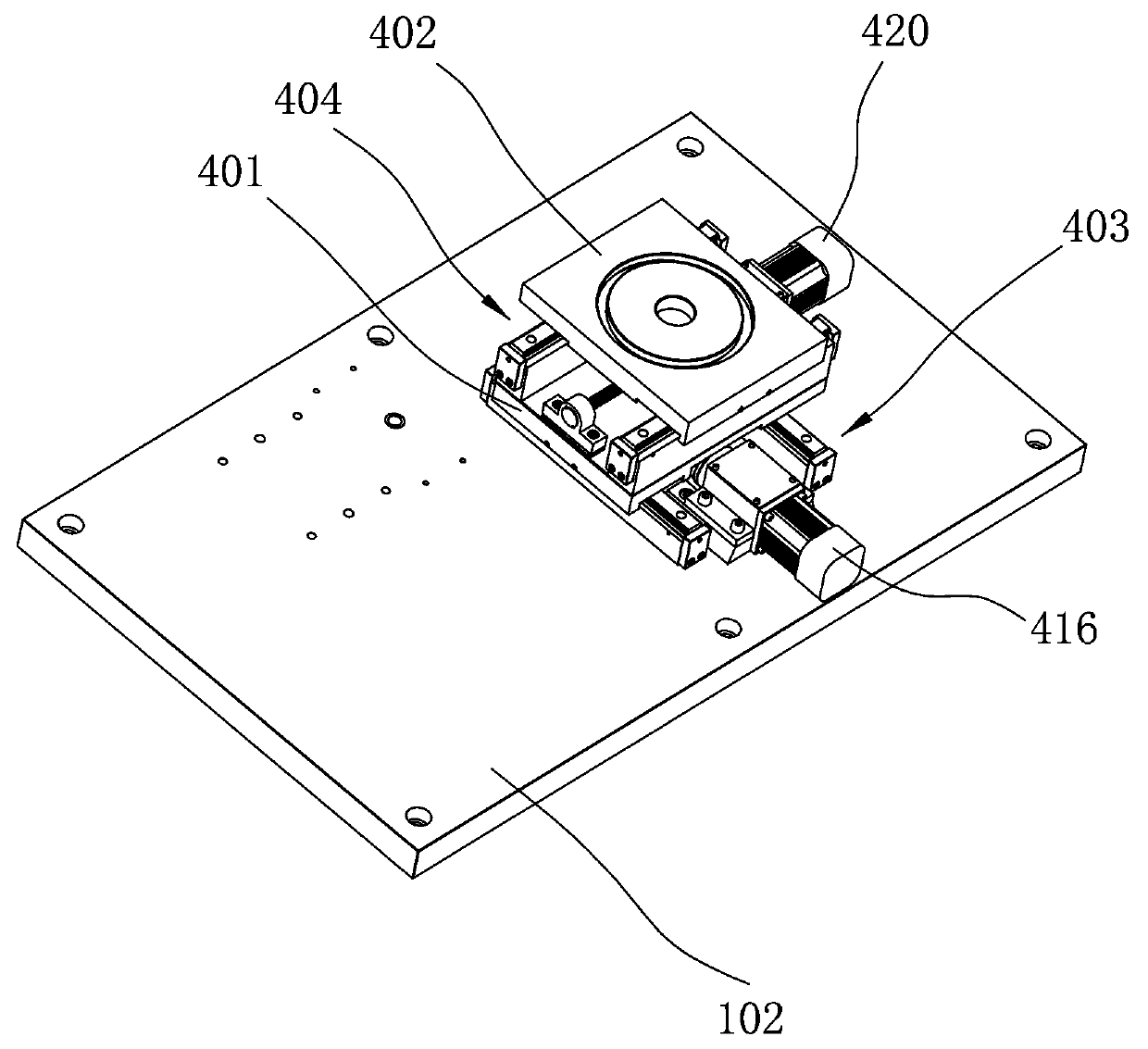

[0022] The workbench 100 includes a base bracket 101 for installing the grinding device 200 and the drill bit position adjustment device 400 and a base 102 installed on the base bracket.

[0023] The grinding device 200 includes a support frame 201 , a grinding motor 202 installed on the support frame 201 , and a grinding wheel 203 installed on the output end of the grinding motor 202 . The grinding wheel 203 is covered with a grinding wheel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com