Method and device for ice adhesion strength normal force on material surface

A technology of adhesion strength and test method, applied in the direction of measuring device, analyzing material, using mechanical device, etc., can solve the problems of excessive matching, complex test device, poor test repeatability, etc., to ensure uniformity and operation. Convenient, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

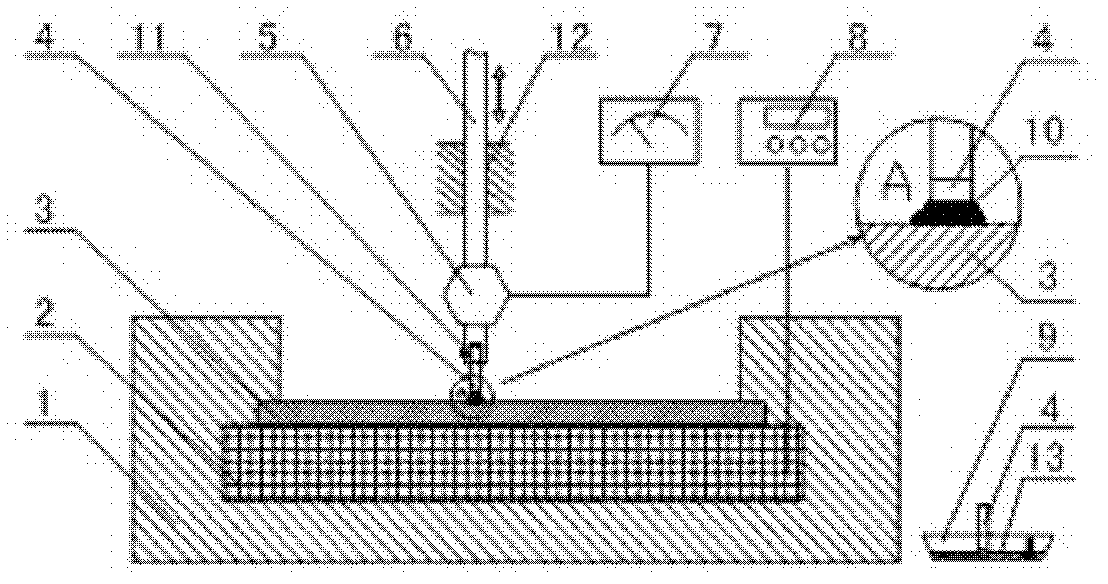

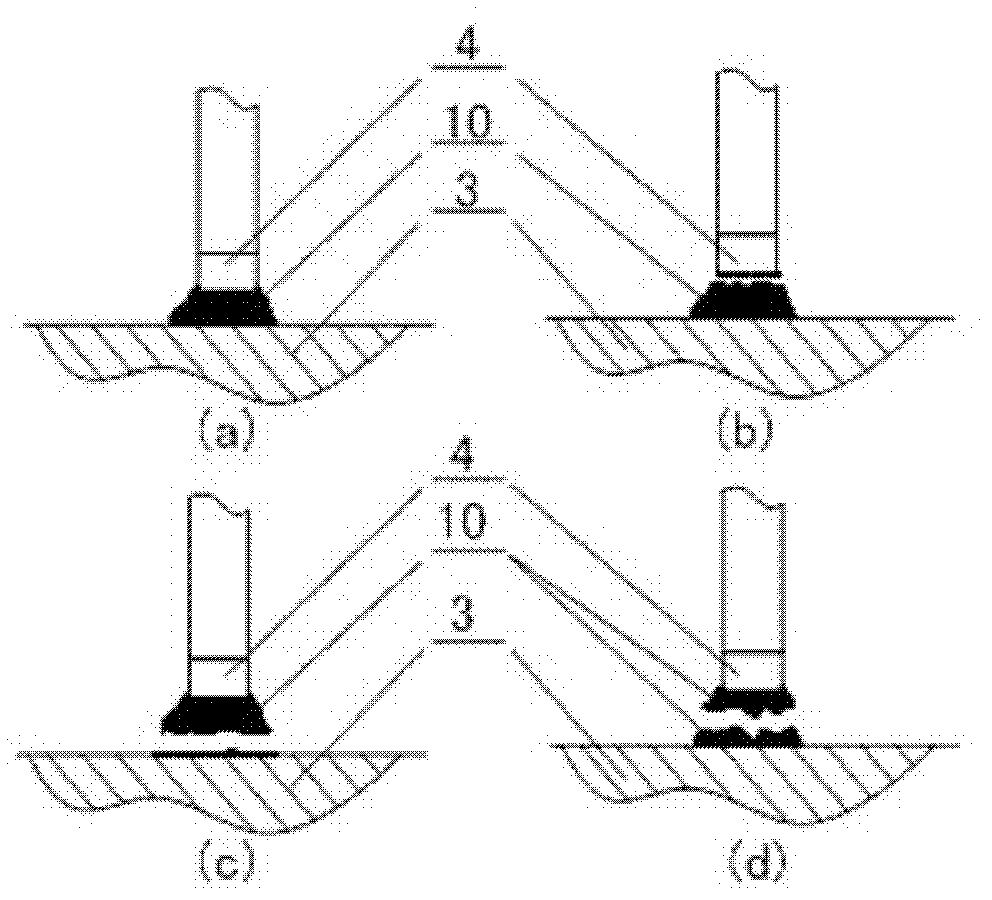

[0039] The method and device for testing the normal force of the ice adhesion strength on the material surface disclosed by the invention characterize the ice adhesion strength of the surface of the sample by testing the maximum normal force when the surface of the peeled sample is frozen. The difference from the existing ice adhesion strength test method: the method disclosed in the present invention is to first refrigerate the test sample 3 and keep it warm, and then the water 13 dipped by the adhesion probe 4 is mixed with the surface of the test sample 3 Make icing. During the peeling process, the adhesion probe 4 is normally stretched by the push-pull mechanism 6 to make it peel off from the ice on the surface of the sample 3 to be tested, and the maximum peeling force in this process can be determined by the load cell 5 . The test sequence of the disclosed method of the present invention is:

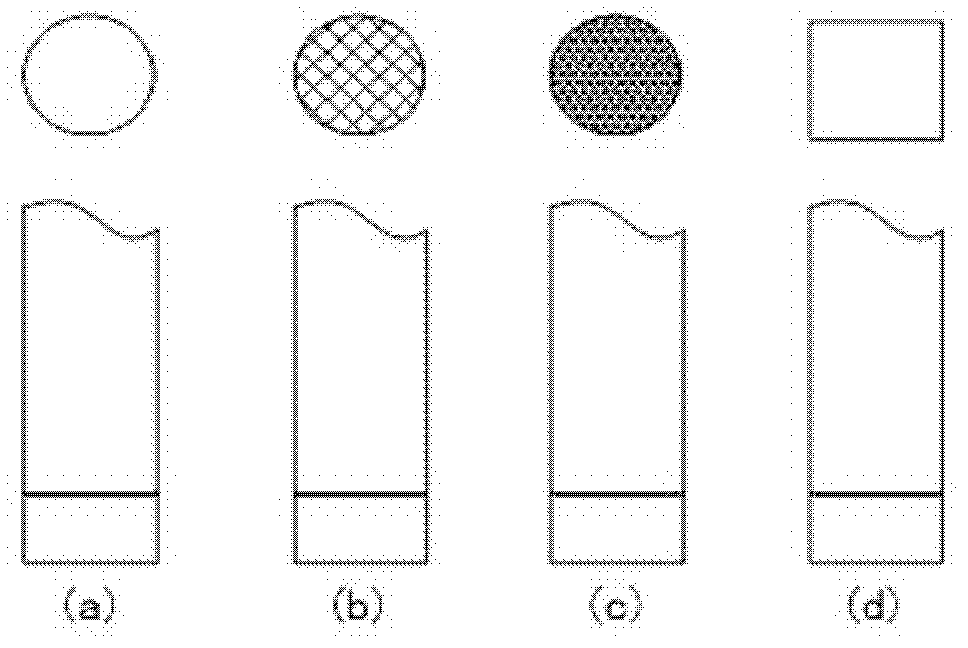

[0040] (1) The size of the sample 3 to be tested is determined according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com