Device and method for testing interlaminar tensile strength of 3D printed concrete member

A 3D printing and tensile strength technology, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems to be discussed, reduce the test error, the test principle is simple and clear, improve the The effect of the test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

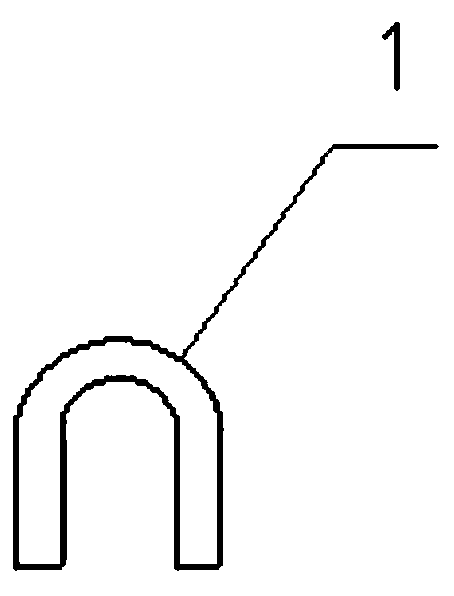

[0029] The present invention provides a device for testing interlayer tensile strength of 3D printed concrete components, see Figure 1-6 , including: an indenter 1, a fixed rod 2 and a bracket 4; the indenter 1 is in contact with the indenter of the universal material testing machine;

[0030] The support 4 is composed of left and right parts, the left and right parts are symmetrical and identical, and a single support is stable and upright when placed on a horizontal plane; the upper surface of the support 1 is provided with a groove 7, and the groove 7 is close to the inner surface The first protrusion on the side of the ball is 1-5mm higher than the other protrusions, see image 3 ; The inner surface of the support 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com