Axial electromagnet bearing

An electromagnetic bearing and axial technology, which is applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of low utilization rate of permanent magnets and insufficient axial size, and achieve compact structure, small axial size, and high current The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

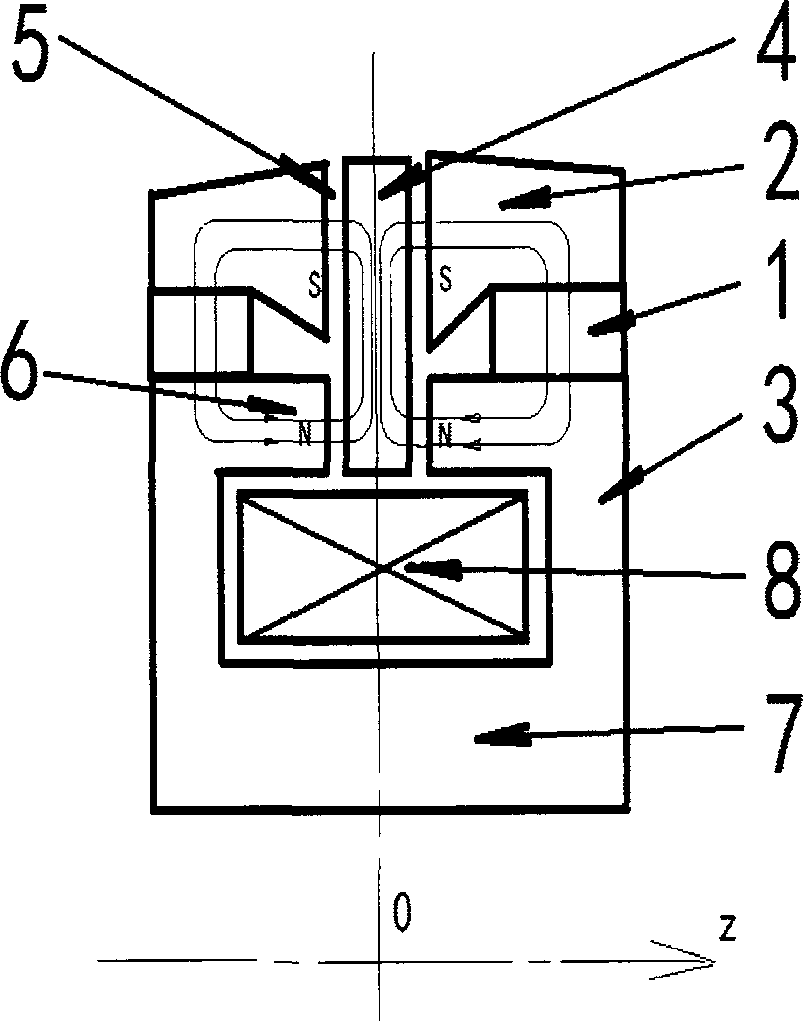

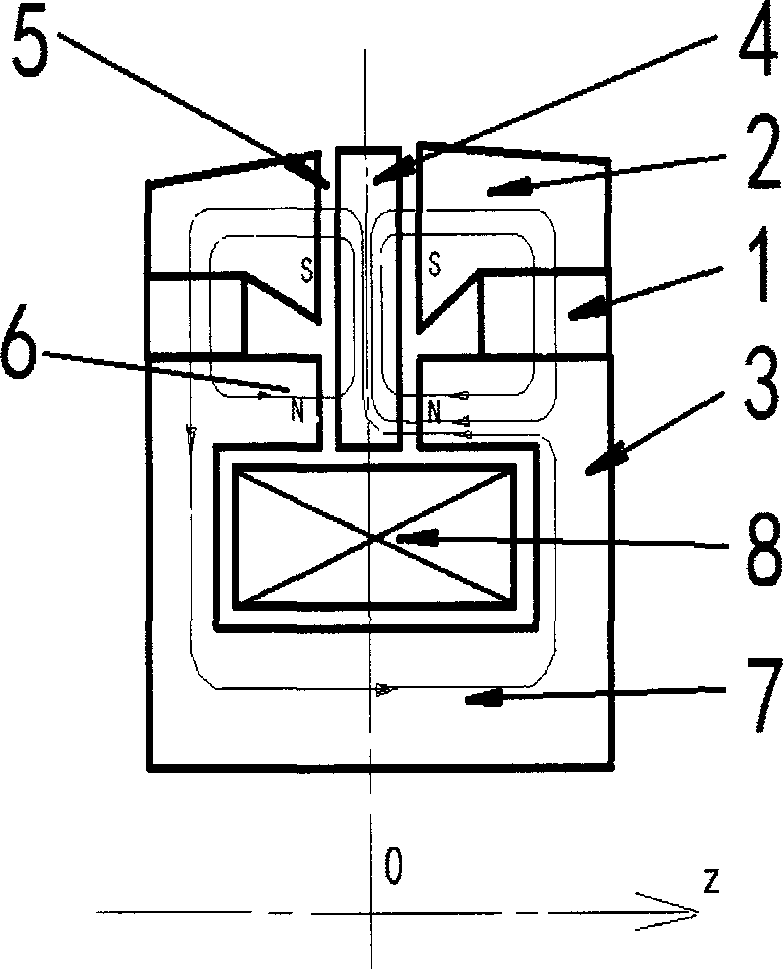

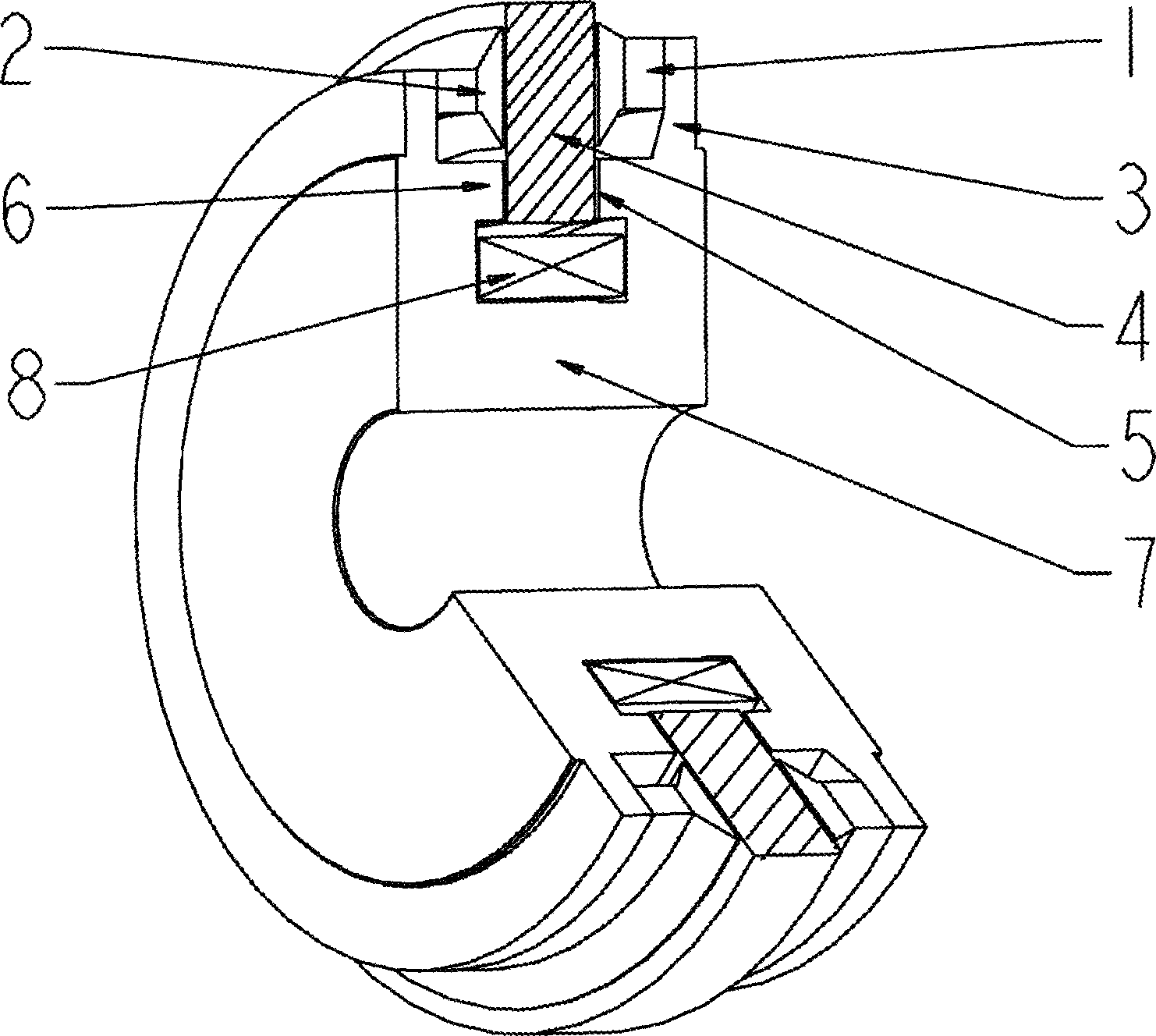

[0025] figure 1 It is a schematic diagram of the magnetic force lines of the permanent magnet bias flux along the magnetic circuit. The polarity of the magnetic poles on both sides is axisymmetric to the center line of both sides, and the S poles are all outside according to the radial direction. The two sides of the bias flux magnetic field line respectively pass through the high magnetic flux density small magnetic pole 6, the air gap 5, the rotor suction cup 4, the air gap 5, the low magnetic flux density large magnetic pole 2, and the bias permanent magnet 1 to form a loop, the low magnetic flux density is large The magnetic pole 2 has a large area so the magnetic flux density is low. The volume of the bias permanent magnet 1 on one side is larger than that on the other side, that is, the magnetic force of the air gap 5 on one side is greater than that on the other side. When the rotor is erected, the rotor sucker 4 has a suction difference at the balance position to bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com